RELATED BLOG

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17Learn More

-

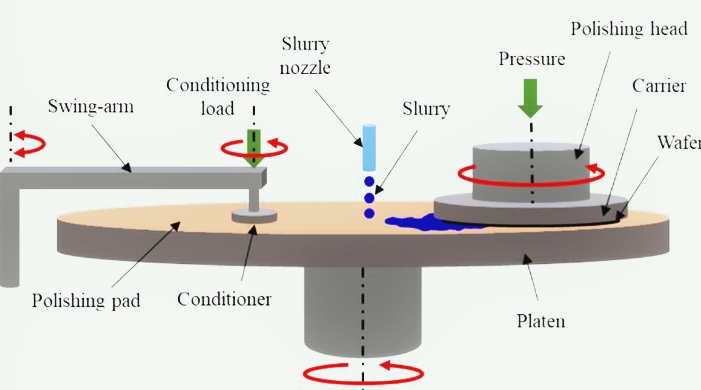

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07Polyurethane polishing pads are currently the most commonly used material in sapphire CMP.

Learn More

-

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04In the field of wood turning, the sharpness and condition of the tool directly determine the precision and texture of the finished product, and the grit wheel is a core factor affecting the tool’s polishing effect. Different grit wheels will bring drastically different cutting performances, and the combination of wheel material and polishing system will also affect the overall turning process. This article will comprehensively break down the logic of grit wheel selection for wood turning tools, providing wood turners with a complete solution from basic understanding to practical selection.

Learn More

-

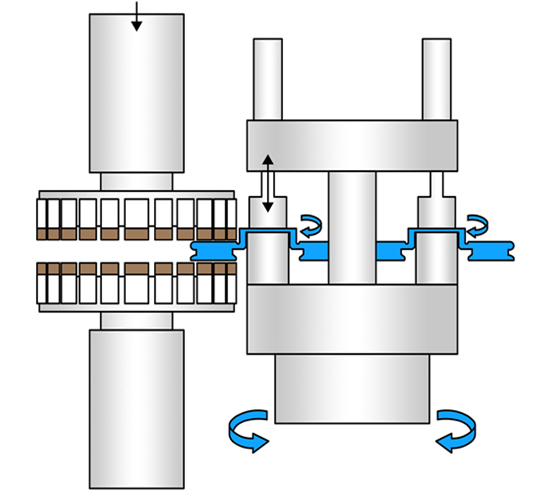

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18Learn More

-

How to grind suspension springs?

2025-11-11Learn More

-

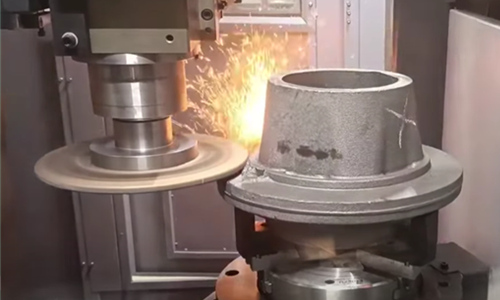

How to machining carbon-ceramic brake disc?

2025-11-05Machining carbon-ceramic brake discs demands advanced superabrasive technology. The choice of diamond bond — resin, vitrified bond diamond grinding segment — determines the success of the operation.

Learn More

-

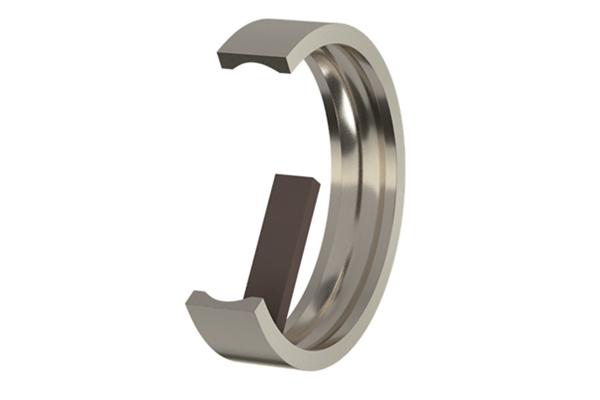

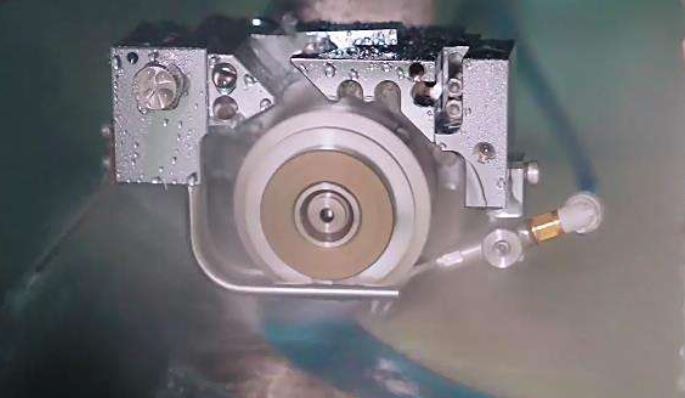

Application of CBN Superfinishing Oilstones in Bearing Raceways

2025-10-16Learn More

-

The difference between grinding fluid and polishing fluid

2025-09-26Learn More

-

How to suppress the generation of grinding cracks

2025-09-19Learn More

-

How to choose the dicing blade In the substrate processing?

2025-09-11Learn More