How to choose dressing speed?

Why need dressing grinding wheels?

During the grinding process, the state of the grinding wheel will directly affect the grinding result. The state of the grinding wheel includes changes in the cutting force and shape of the grinding wheel. These changes will affect the yield and reproducibility of the ground product.

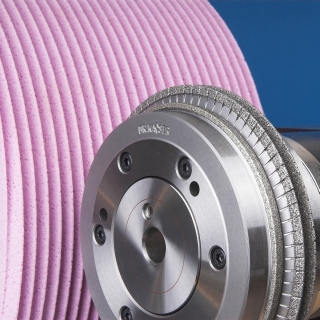

Moresuperhard can provide single point diamond dresser , diamond rotary roller dresser, conventional abrasive grinding wheel for dressing different kind of grinding wheel, any dressing method can inquiry us!

What is the main reason for the loss of cutting force of the grinding wheel?

1. During the grinding and extrusion process of abrasive grains, the edges and corners are gradually rounded, which we call passivation. At this time, the self-sharpening ability of the grinding wheel does not play a role in time, which will reduce the cutting force and cannot effectively perform the grinding function.

2. Debris will be generated during the grinding process, especially for viscous materials. If the pores of the grinding wheel are not large enough or the porosity is low, debris will easily fill the pores and cause blockage. As a result, the grinding wheel becomes a non-serrated plane and loses cutting force.

During the use of the grinding wheel, wear and tear will occur. Such loss will cause the gradual loss of the roundness of the grinding wheel and the unevenness of the grinding surface of the grinding wheel. This situation will cause problems such as deflection during grinding and reduced grinding efficiency.

In these unstable states, the grinding wheel must be trimmed to restore the cutting force or true roundness of the grinding wheel. However, because the grinding wheel rotates at a high speed during processing, it is often impossible to directly observe whether the grinding wheel has lost its cutting force or is uneven from the naked eye. However, many grinding phenomena will occur when the cutting force is lost. If these phenomena occur, it can be estimated whether the grinding wheel needs to be dressed.

The insufficient cutting force caused by passivation and clogging, and unevenness caused by wear will be directly reflected on the grinding result; so when the following conditions occur during grinding, it is time to repair the grinding wheel.

How to choose dressing speed?

If the dressing speed is faster, the serrated part will be thicker, that is, the surface of the grinding wheel will be thicker, and the grinding surface will be rougher, but the cutting force will be better.

The dressing speed is slower, and the sawtooth shape of the grinding wheel surface is smoother, that is, the grinding wheel surface is smoother, the grinding surface is finer, and the cutting force is poorer.

The cutting surface of the grinding wheel is more like each abrasive is like a cutting edge. Use this as the cutting edge to do the grinding action. When the grinding wheel is blunted, we need to repair the sharp edge of the abrasive, basically Yes, the faster, the thicker the shape, the better the cutting force.

Dressing too quickly can also cause problems. Dressing is fast, and the distance of each jump is large. Although the abrasive is sharpened, because the moving speed is too fast, the abrasive may be skipped for dressing. So not every grit is actually dressed, thus causing poor cutting force. More importantly, the sharpness retention of the grinding wheel will not be enough, because it is likely that only one-third of the abrasive is trimmed, and only this part of the abrasive has cutting force, and of course it will be blunted soon. Therefore, although the cutting force is better if the repair is faster, it is also necessary to pay special attention to the fact that a lot of abrasives may be missed if it is too fast. Therefore, after rough repairing, there may be a good cutting force at the beginning, but the cutting force will be lost soon, which may be caused by the effect of too fast dressing speed.

On the contrary, when the dressing speed is slow, although each abrasive can be dressed evenly, if it is too slow, there may be no cutting force at all, and even the whole abrasive will be pulled out due to too much resistance, and the abrasive will fall off If the speed is too fast, the grinding wheel may often lose sand.

Therefore, the dressing speed has a certain range, which can be set according to the abrasive, the size of the abrasive, the speed of the grinding wheel, and so on. Sometimes, if the cutting force is not enough, the maintenance is not good, or the sand is lost, it is likely to be caused by too fast or too slow abrasive repair.

—EDITOR: Doris Hu/Wing She

—POST: Doris Hu