How to high precision rotor grooving?

CBN has an extremely high hardness, second only to diamond. But it is better than diamond in heat resistance and chemical inertness to iron. Because CBN abrasive has the advantages of good wear resistance, non-ferrophilic and high thermal stability, so CBN grinding wheel in the grinding of difficult materials can keep sharp state for a long time, so the grinding force is small, the heat is small, the grinding temperature is low, the grinding parts of high precision, high production efficiency.

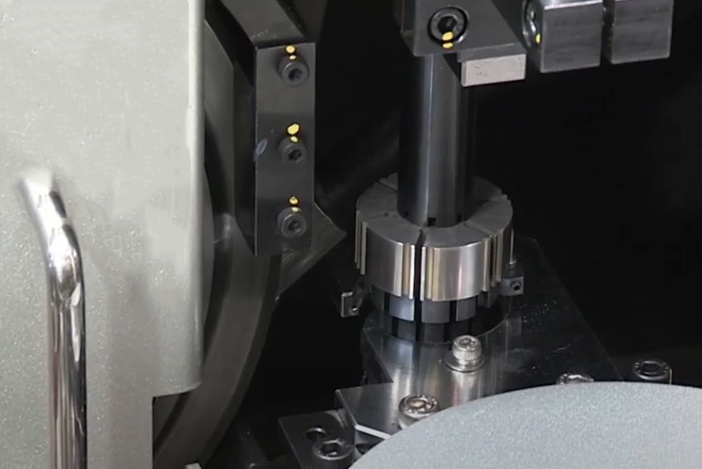

The rotor is a key part of the vane pump/motor. The material is 38CrMoAlA and the surface of the rotor groove is nitrified. Because the size accuracy, shape and position tolerance and surface roughness of this part are high requirements, the groove is narrow and deep, so the grinding wheel should be considered to have chemical inertia and high hardness, not need dressing in the process of use, so the selection of vitrified or electroplated CBN grinding wheel is more suitable.

Conventional abrasive grinding wheel processing can not achieve the accuracy requirements, based on the CBN abrasive has incomparable advantages of other ordinary abrasives, electroplated CBN grinding wheel is easy to make, and its runout is completely determined by the grinding wheel matrix. Electroplated CBN grinding wheel can be used without dressing, and the grinding wheel matrix can be reused after repairing after the coating abrasive particles are utilized to the maximum extent, so it is convenient and economical.

CBN abrasive has high wear resistance, high hardness and high chemical inertia, so CBN in narrow groove grinding, can keep sharp state and control heat for a long time, low grinding temperature, and good grinding wheel retention. Because electroplating CBN grinding wheel is easy to make, the runout of the grinding wheel is completely determined by the steel grinding wheel matrix, so the electroplated CBN grinding wheel does not need dressing before and during grinding.

Based on the above reasons, a single cutting and grinding scheme of rotor groove on nc machining center was proposed by using vitrified or electroplated CBN wheel.

It is convenient for the workpiece to be positioned and clambed to the top of the two centers, and the dividing device is installed. It is convenient for the workpiece to be measured online, and the numerical control machine tool is ideal.

Moresuperhard can provide coarse and fine grit 3A1/14A1 vitrified CBN grinding wheel and electroplated CBN grinding wheel for rotor groove machining.

Rotor slot grinding wheel (morediamondwheel.com)

The machine tool spindle is required to have a high speed, and the speed range can be changed and the machine tool must work smoothly.

Grinding amount:

-Coarse grinding

* Grinding wheel speed: Vc=15m/s

* Grinding depth: AP =0.02mm

* Feed speed: Vs=0.6mm/min

-Fine grinding:

* Grinding wheel speed: Vc=17.5m.s

* Grinding depth: AP =0.01mm

* Feed speed: Vs=0.5mm/min

Cooling fluid

At high grinding temperature, CBN abrasive particles will undergo chemical reaction when they meet alkaline aqueous solution, and the result will destroy the grain shape. Therefore, when CBN grinding wheel is grinding, only oily coolant can be used, but not water-based coolant.

Customer feedback effect

Using electroplating CBN grinding wheel to grind rotor groove on nc machining center, the rigidity of grinding wheel is greatly improved, and the life of grinding wheel is increased 10 ~ 20 times than that of ordinary silicon carbide grinding wheel. The grinding ratio of CBN grinding wheel is more than 100 times that of conventional grinding wheel, the grinding surface has no burn and crack, and the surface integrity meets the requirements. The processing accuracy can meet the technological requirements. Moreover, CBN grinding wheel does not need dressing, thus saving dressing tools and downtime, and greatly improving productivity.

—EDITOR: Doris Hu

—POST: Doris Hu