Aluminum Alloy Hole Machining Tool

Compared with steel, aluminum alloy has the characteristics of soft material, poor rigidity, and low elastic modulus. In addition, the difficulty of hole processing is high, which leads to the need for more efficient and high-precision tools when processing aluminum alloy holes.

The material and geometric parameters of the tool have an important influence on the cutting force and cutting heat. Choosing a suitable tool can not only ensure the stable quality of the workpiece, but also improve the processing efficiency and bring more value returns.

PCD material has extremely high hardness and wear resistance, low friction coefficient, no affinity with non-ferrous metals, easy outflow of chips, high thermal conductivity, and it is not easy to generate built-up edge during high-speed cutting. PCD reamer has unparalleled processing advantages in cutting force and surface roughness. The tool has a long service life, which effectively reduces the number of tool changes and tool adjustment time, and can realize multiple grinding, which significantly improves the accuracy and smoothness of the machined surface.

PCD reamer

Product introduction:

Diameter: D4.00-D35.00

Number of blades: 2

Tool holder type: HA (DIN6535), HSK, BT

Cooling: internal cooling (customized external cooling)

Blade material: CKD10

Tool body material: cemented carbide (≤D20), steel (>D20)

Product advantages:

·Single-stage PCD reamer, suitable for reaming products of aluminum and aluminum alloys, and other non-ferrous metal materials.

· RC301 machining through hole

· Reaming accuracy H7

· Cooling on both sides

· Front port cooling

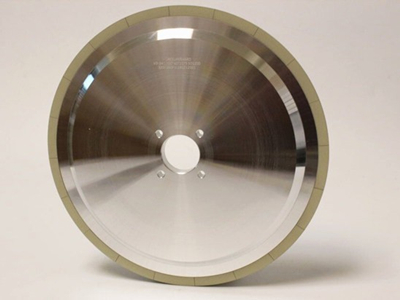

MoreSuperHard provide the Cylindrical Diamond Wheel for PCD Reamer Grinding, If you are interested, Please go to our website to find more information.