Application of Vitrified Diamond Wheel in Thermal Spraying Industry

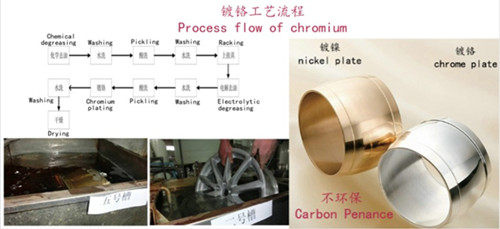

New materials often have a domino effect on aerospace processing technology. Environmental issues have forced the material to change from traditional chrome plating to high-speed oxyfuel (HVOF) spraying, which in turn affects people’s choice of grinding wheels.

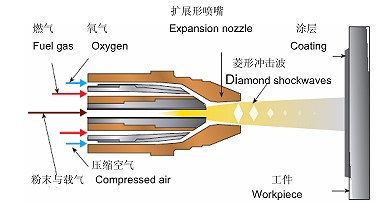

Traditional nickel and chromium plating processes used to harden or repair aerospace components can generate emissions that are harmful to the environment. Therefore, nickel and chromium are rapidly being replaced by HVOF (High Velocity Oxygen Fuel) coatings. The application process is also called “flame coating”.

This high-temperature thermal spraying technique can deposit corrosion and wear resistant materials like tungsten carbide or chromium carbide in a dense, strong and hard layer. HVOF coatings can be up to 90% harder than their alternatives, so they provide superior protection for critical wearing parts, which is good news. The bad news is that HVOP coatings need to be actively processed to make their rough, irregular surfaces meet the final geometry and tolerance requirements.

The primary condition of HVOF spray grinding is to grind HVOF components at the best cost and efficiency. Three things are required: super-hard, high-end CNC grinding system and automatic rotary dressing, carefully selected diamond wheels, and optimized grinding technology.

HVOF spraying formula, part or size of grinding wheel. These grinding processes are a single setting and no interference at all. In all stages of the automatic dressing process of ceramic diamond wheels. Using different dressing parameters, rough grinding and finishing can be performed at the same time. Automatic trimming is performed at specific intervals, which also results in an unusually consistent surface finish and displacement measurement from part to part.

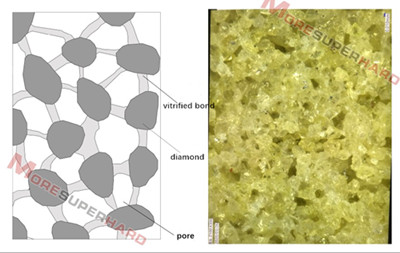

Due to the vitrified diamond grinding wheel can be rotated and dressed on the machine(while the resin diamond grinding wheel cannot), it avoids the need for a separate machine or grinding wheel for processing. The new diamond layer is exposed during the dressing process. The new diamond layer is exposed during the dressing process. This makes it possible to control the cutting behavior of the grinding wheel during the dressing process, so as to achieve the desired effect.. The rotary dresser can also be rotated in reverse, thus providing a higher surface finish. It is worth noting that the grinding wheel is not very sharp in this case, which is why it can bring better surface finish. However, resin bond grinding wheels also require alumina dressing rods. This involves the operator picking up the dressing rod and pushing it into the grinding wheel to expose the cutting area, thus introducing uncontrollable variables into the process. According to different operators,the dressing rod is applied under different pressures and creates different conditions for the grinding wheel according to the length of time. The combination of the vitrified diamond grinding wheel and the rotary dresser can dress a consistent amount at a continuous and stable feed speed, so that stable results can be obtained.

Vitrified diamond grinding wheel not only has the wear resistance of metal bond and the porosity of vitrified bond. There are many advantages: high abrasion rate, minimal bond/workpiece interaction, excellent chip and coolant carrying capacity, good sand fixation ability and tool life, reduce surface damage to the self-sharpening behavior of the work piece, and change the grinding wheel Grit Selection and customization of hole structure.

When roughing with vitrified grinding wheels, the removal speed should be more than 50% faster. Sharper cuts and no dressing cycles, which means more time to process the workpiece. Establishing the correct dressing cycle is crucial in order to develop a production and cost-effective HVOF grinding process for customers.