Application research of aluminum alloy in automotive lightweight field

It is possible to make auto parts with aluminum alloy instead of steel because of its advantages such as light weight, high specific strength, corrosion resistance, good formability and recycling.

At present, many domestic and foreign automobile enterprises have realized the lightweight upgrade of aluminum alloy vehicles. Compared with the traditional steel car, the aluminum body can reduce the overall weight by 30% ~ 40%, and the aluminum engine can reduce the weight by 30%. Moreover, the vehicle is light and strong, which is convenient for modularization, personalized design and diversified layout of the vehicle structure. It not only saves energy and reduces emissions, but also improves the vehicle’s handling stability and collision safety.

At present, there are three main ways to achieve vehicle lightweight:

(1) Lightweight materials, such as to increase the use of light alloy, high strength steel, high performance composite materials in cars.

(2) Lightweight structural design, such as thin-walled and hollow-out design of components.

(3) Manufacturing processes are lightweight, such as gas-assisted forming, hydraulic bulging and solid particle medium bulging integrated forming processes instead of the traditional unequal thickness injection molding and secondary welding processing

The application of aluminum alloy in the light weight of automobile body

The automobile body is generally composed of covering parts and frame structure. Covering parts are assembled on the frame structure to form the appearance of the whole vehicle. With the further improvement of people’s aesthetic requirements on the appearance of automobiles, covering parts tend to develop in the direction of beauty, light weight and low wind resistance. The exterior plate of the covering piece is the intuitive perception part of the customer, which pays attention to the forming process, corrosion resistance, the deformation of electrophoretic paint and the finish of the paint, but also takes into account the matching and feasibility of the vehicle shape.

AA6000 series heat-treatable aluminum alloy has high strength, good forming performance, and high spray painting, baking and hardening characteristics. It has almost become a special aluminum alloy for the outer plate of covering parts. In addition, AA7075, AA7N01 and other 7000 series of ultra-high strength aluminum alloy in the outer plate of the covering parts are also in the forefront of research, which is expected to obtain a wider range of promotion and application.

Different from the high standard requirements for the surface quality of the outer panel of the covering panel, the inner panel of the covering panel focuses more on the deep drawing and drawing properties of the material, good bonding and supporting strength.

In recent years, AA5754 and AA5182 are the most commonly used aluminum alloys for the inner plate of covering parts, with superior forming and welding properties. In addition, in case of vehicle collision, aa554 and AA5182 show good energy-absorbing buffering effect, which can provide better safety protection for passengers.

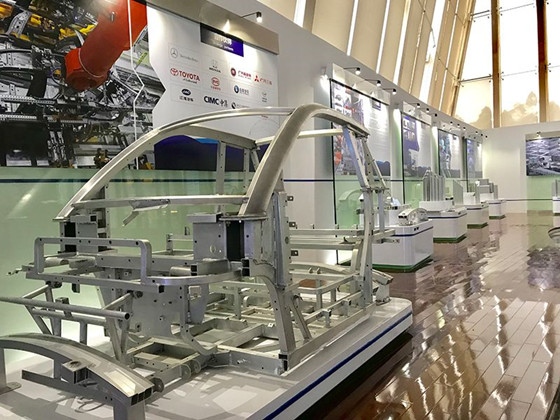

The frame structure of the car body is an important support for the composition of the car. Chassis, electrical appliances, powertrain and other components are assembled on the frame of the car body, which is the basic carrier of the whole car. Whether 3H frame structure or keel frame structure, its rigidity and torsional resistance are important parameters that cannot be ignored.

The use of aluminum alloy body frame can effectively reduce the vehicle preparation quality and improve the mechanical and safety performance of the vehicle. According to OPEL, the aluminum body is 23% better in quality and performance than steel, 74% better in torsion and rigidity, and 62% better in bending.

The analysis shows that, compared with the traditional steel body, the higher the aluminization rate is, the better the vehicle’s lightweight effect is, the more conducive to energy conservation and emission reduction, and the further optimization of the vehicle’s operational stability and ride comfort. However, due to the application of aluminum alloy materials in the body, such as aluminum alloy forming process and die, specific environmental performance and maintenance methods are less studied, and the cost is more expensive than steel, aluminum alloy has been mainly used in high-end cars and new energy vehicles with extremely strict requirements on lightweight for a long time.

In recent years, with the further in-depth research of aluminum alloy materials, and the gradual reduction of manufacturing and use costs, its use in the middle and low-end vehicles are also gradually increasing, I believe that in the near future, the use of aluminum alloy body will be more popular, comprehensive coverage of body assembly parts.

Application of aluminum alloy in chassis lightweight

As one of the three major parts of an automobile, the chassis system carries the functions of transmission, driving, steering and braking. It is directly related to the vehicle’s passability, operation stability and ride comfort, and is also one of the systems that customers focus on and perceive.

The traditional chassis parts are cast iron parts with large quality and easy to rust. With the development of new materials and new technology, aluminum alloy has been widely used in automotive chassis rims, steering knuckles and other key fatigue structural systems. Tebaldini et al., based on a356-T6 aluminum alloy rim fatigue crack research, showed that fatigue crack always starts from pore, and low pressure casting defect is one of the important factors leading to fatigue crack of rim.

Compared with forging, aluminum alloy rim produced by low pressure casting process has better cost efficiency and complex forming performance, but due to the unavoidable casting defects, the mechanical properties of cast aluminum rim are slightly lower than that of forged aluminum rim. The use of aluminum alloy rim can effectively reduce the unsprung mass of the vehicle driving system, absorb the vibration and torque generated during the driving process, and improve the driving stability, operating stability and ride comfort of the vehicle. Compared with steel rim, aluminum alloy rim heat dissipation performance and heat transfer performance is superior, can effectively send out the braking system and driving system heat, reduce the thermal load, improve the vehicle driving safety.

The steering knucks in the chassis assembly are the key structural parts of the automobile steering system. They play an important role in controlling the driving direction of the vehicle and bear variable impact load during the driving process of the vehicle, which is prone to fatigue failure.

The results show that compared with the inevitability of casting defects, the mechanical properties of forged parts are better than those of cast parts, which can better meet the performance requirements of aluminum alloy for automobile chassis parts. Therefore, the low cost and high performance forging process will become the focus of future research in the field of lightweight aluminum alloy chassis parts.

Application of aluminum alloy in powertrain lightweight

With the continuous improvement of power performance requirements of the majority of users, light weight, low consumption, good heat conduction and corrosion resistance has become an important symbol of an excellent engine, and aluminum alloy material perfectly gives consideration to the above performance, making it possible to replace the ductile iron manufacturing engine.

In view of the special working environment of the engine, it is required that the selected aluminum alloy material should have the characteristics of high temperature resistance, impact resistance, corrosion resistance and fatigue resistance, and be able to maintain good mechanical properties under the working environment of high temperature and high pressure, repeated vibration and impact.

The results show that proper heat treatment is helpful to improve the anti-fatigue performance of casting engine cylinder block, and the fatigue limit of aluminum alloy will be increased with the refinement of grain structure.

At the same time with the development and evolution of the cylinder thermal spraying technology, can effectively increase the strength of the cylinder wall, reduce the cylinder wall and piston friction, reduce the cylinder volume, improve the service life of the cylinder, but also reduce the quality of the engine, so that the engine towards light, fast, good, the direction of the province development. With the continuous improvement of power, emission and lightweight requirements, the whole vehicle powertrain system is facing a huge challenge, requiring the engine, gearbox, drive motor and other powertrain components to develop towards the extreme lightweight direction.

The research of lightweight aluminum alloy powertrain parts focuses on the material performance improvement, optimization calculation and multi-part integration technology under extreme working conditions to reduce the volume and quality; At the same time in the forming technology and production cost should also have a breakthrough.

The application of aluminum alloy is more and more extensive, the processing of aluminum alloy is also very important. More Superhard Products Co.,Ltd. focuses on aluminum alloy and other precision parts CNC processing, can provide aluminum alloy processing solutions, whether grinding wheel or cutting tool, More Superhard company can provide you with quality products.