Bearing super finishing

What are bearings?

Most bearings seen in daily life are ordinary bearings. However, high-end precision bearings applied in aero-engine, high-precision machine tool equipment, high-speed railway, instrumentation and other fields have unimaginable complexity in technology. The quality of a bearing is determined by its accuracy, performance in vibration, noise and noise, life and reliability, and high-speed performance. In the process of bearing production, the most critical links include forging, heat treatment, grinding, super finishing, rust prevention and so on.

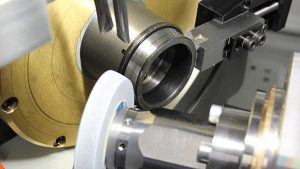

In the process of grinding, the working surface of bearings is grinded by high-speed rotating grinding wheel. In the process of grinding and superfinishing, the high precision bearing with excellent performance can be made only if the surface roughness meets the specified standard.

Abrasive tools play a key role in the final quality of bearings and can significantly affect the efficiency of grinding process.

Bearing grinding process is divided into:

Centerless grinding of bearing outer ring and cylindrical grinding of oversized bearing outer ring

Bearing outer ring inner raceway grinding

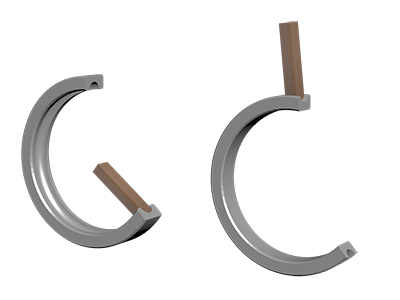

Bearing outer ring inner raceway superfine

Bearing inner ring outer raceway grinding

Bearing inner ring inner hole grinding

Bearing inner ring outer raceway superfine

Bearing inner and outer ring end grinding

What is superfinishing?

Superfinishing, generally refers to the good lubrication condition, the processed workpiece according to certain rotating speed, oil stone according to certain pressure elastic pressure processing on the surface of workpiece, and in the direction perpendicular to the workpiece rotation according to certain rules for reciprocating oscillation motion of a kind of automatically end finishing machining method High levels of superfinishing can influence on the performance of the bearing work:

- Improve the rotation accuracy of bearings and reduce the vibration and noise of bearings

- Improve bearing capacity of bearings

- Improve the lubrication effect of bearings and reduce wear

- Reduce the heat of bearings during work

The use of superfinishing oil stone with excellent quality is the premise of the existence of superfinishing technology. The characteristics of oil stone such as good cutting performance, slow loss and sufficient strength ensure the excellent completion of superfinishing.

Moresuperhard, the bearing inner and outer ring raceway and roller super finishing, can improve the bearing precision and surface finish, so as to extend the service life of the bearing and reduce the bearing running noise.

—EDITOR:Doris Hu

—POST:Doris Hu