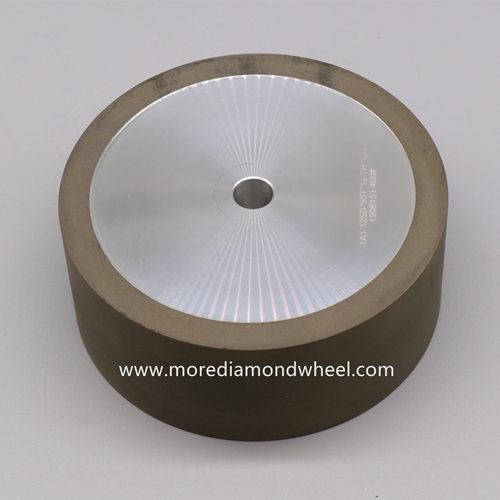

Selection of internal grinding wheels

When the internal grinding is performed in the inner hole, and if the diameter of the grinding wheel is too large, the contact arc between the grinding wheel and the work-piece increases. It increases the grinding heat and is difficult to cool and remove the debris. If the diameter of the grinding wheel is small, it is difficult to achieve the ideal grinding speed(30m/s-50m/s), making the grinding thickness increased, the load of the abrasive grains increased, and it is easy to be blunt, and the surface roughness of the inner hole is increased.

In order to obtain a better grinding effect, should keep the appropriate ratio of the diameter and inner hole of the grinding wheel. This ratio is usually within 0.5-0.9. When the aperture is small, if the problem is the peripheral speed of the grinding wheel is low, should take the large ratio. When the pitch is small, and the problem is the difficulty of cooling and debris removal, should take the small ratio.