How to Dress Vitrified CBN wheels?

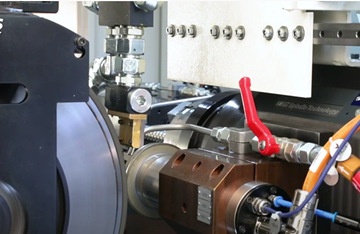

Vitrified CBN grinding wheel is widely used in high-precision CNC Grinding of key components such as crankshafts

Vitrified CBN grinding wheel is widely used in high-precision CNC Grinding of key components such as crankshaftsand camshafts of automobile, motorcycle engine, marine engine, and internal combustion engine manufacturing. In

the 1990s, the appearance of CBN CNC crankshaft grinders with integrated processes, which realized the complete

grinding of the crankshaft main journal and connecting rod journal in one clamping. The CNC grinding machines

produced by Japan’s TOYODA, Germany’s JUNKER, Germany’s Naxos-Union, and the United States’ LANDIS all use

high-speed ceramic CBN grinding wheels, with a maximum speed of 200 m/s. German companies such as WINTER,

WENDT, and TYROLIT of Austria all use the grinding wheel with the speed above 120 m/s and the maximum speed

up to 160 m/s. The development of high-speed machine tools need to develop the corresponding high-speed grinding

wheel.

domestic grinding machines with a speed of 60 m/s,

but its high speed and high efficiency could not be effectively displayed. With the continuous introduction of high-speed CNC grinding machines at the beginning of this

century, the speed of CBN grinding wheel developed in China has reached 80 m/s ~ 125 m/s, and it has been applied in camshaft processing, showing obvious advantages

such as high degree of automation, high processing efficiency and stable workpiece quality, laying a good foundation for the promotion and application of vitrified CBN

grinding wheel.

grinding of difficult materials, high-efficiency molding grinding and other processing fields. During the grinding process, the grinding grains on the working surface of the

grinding wheel will gradually passivate due to the grinding force, high temperature and adhesion of the grinding area. At the same time, the grinding grains on the working

surface of the grinding wheel will lose the correct original geometric shape due to uneven wear. In addition, because of the small grinding debris of high-speed grinding, it

is easy to block the gap on the working surface of the grinding wheel. In order to keep the CBN grinding wheel always in the good grinding state, the grinding wheel must

be trimmed during its grinding process. This problem has become a very important research topic in the application field of the CBN grinding wheel.

The dressing of CBN grinding wheel can be divided into two steps: Truing and Dressing.

Truing is to make the grinding wheel reach the required geometric shape and dimensional accuracy by changing its macroscopic shape

of the grinding wheel, and make the

grinding wheel tip finely broken to form a sharp grinding edge. Dressing is to remove the binder between the grinding grains of the

grinding wheel, so that the grinding grains protrude from the surface of the binder, forming the necessary chip space so that the

grinding wheel has the best grinding capacity. According to the specific situation, shaping and sharpening can be unified or completed at the same time, also can be done

step by step.

1. The Shaping/Truing Method of Vitrified CBN wheel

There are many truing methods of vitrified CBN wheel, such as turning shaping, rolling shaping, grinding shaping and so on. In recent

years, laser shaping also appeared.

(1) Turning Truing

Turning shaping/truing is to use single-particle diamond dresser or diamond dressing tools to turn the grinding wheel to achieve

the purpose of shaping.

A. Single Point Diamond dresser Shaping/Truing

The single-particle diamond dresser has very high hardness and good wear resistance, so it is often used for dressing CBN grinding wheel with the ceramic binder or resin

bond. Because the tip of the diamond dresser is subjected to the concentrated and continuous action of heat and force, the wear is severe. Using single-particle diamond

dresser after trimming vitrified bond CBN grinding wheel, grinding wheel surface is not easy to meet the requirements of grinding, due to the small chip space, wide

cutting edge and non-sharp grinding blade, if directly used for grinding workpiece, primary grinding forces and grinding temperature is larger, both prone to vibration

grinding burns or lines, and therefore must use dressing stones to sharp the wheel surface of after-finishing.

B. Blade Type Diamond Dresser Shaping(Diamond Chip Dresser Shaping)

Diamond chip dresser is made by the consolidation of small diamond particles on the carbide matrix by powder metallurgy. Using a

diamond chip dresser, the cost is low and the performance of it does not change much after wear. During shaping, a large dressing

feed can be used without increasing the surface roughness of the grinding wheel. Compared with a diamond pencil, it has obvious

advantages. But turning shaping can only be used for the less-demanding workpiece.

(2) Rolling Shaping/Truing

Rolling shaping is the use of relative rotating motion between the grinding wheel and the rolling wheel, fracture the bond of grinding

wheel and make the abrasive grains to break up and appears micro blades, and use cemented carbide or super hard steel, its manufacture process is simple and chip. In

addition, its main characteristics are high shaping pressure, low dressing efficiency and dressing accuracy, deep surface damage layer after dressing, low sharp cutting edge

density, sharp abrasives and easy to wear. In order to avoid peripheral ripples on the surface of the grinding wheel, the coaxiality of the grinding wheel shaft and the roller

shaft must be controlled.

(3) Grinding Shaping/Truing

Grinding shaping is used for the shaping of the common abrasive grinding wheel, diamond roller and CBN grinding wheel grinding shaping, CBN grinding wheel for low

carbon steel shaping. Grinding shaping of common abrasive grinding wheel is a ceramic bond grinding wheel with green silicon carbide or white corundum as abrasive.

The grinding wheel of CBN can be shaped by an external cylindrical grinding machine. Of course, this method can also be used for sharpening.

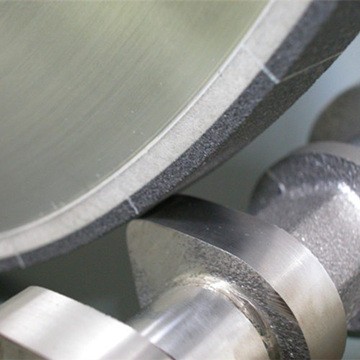

Diamond roller shaping is made of diamond roller by electroplating or powder metallurgy, which rotates with CBN grinding wheel at the same time to produce relative

motion to achieve grinding wheel shaping. Dressing feed and dressing speed ratio (the ratio of the linear velocity of diamond roller to the linear velocity of CBN grinding

wheel) have an important influence on the grinding performance of CBN grinding wheel after dressing. The grinding force of CBN grinding wheel after dressing is smaller

than that after dressing, but the surface roughness of the workpiece is larger. The grinding wheel after dressing with a large dressing feed is sharp, the specific value should

be determined according to the grinding roughness requirements and the characteristics of the grinding wheel. The main advantages of this method are simple structure,

high durability of the roller, the ability to trim the full width of the grinding wheel at the same time, short dressing time, small dressing force, and the ability to duplicate

the contour of the grinding wheel with complicated shape.

2. The Sharpening/Dressing Method of Vitrified CBN wheel

(1) Free Abrasive Sharpening Method

The free abrasive sharpening method includes gas blasting sharpening, ultrasonic vibration sharpening, elastic sharpening, free abrasive extrusion sharpening, and

hydraulic sandblasting sharpening. In short, silicon carbide, corundum or glass beads, and other free grinding grains are used as the sharpening medium and sprayed onto

the surface of the rotating CBN grinding wheel by various methods to remove part of the binder and form a cutting edge to achieve the purpose of sharpening the grinding

wheel. Because the bond of vitrified CBN grinding wheel is hard, the sharpening efficiency of this method is very low, and it has not been popularized in industry.

Consolidation sharpening tool sharpening method is divided into common abrasive sharpening block cutting sharpening, common grinding wheel grinding sharpening

and oil stone sharpening.

A. Common abrasive sharpening block cutting sharpening is to press the sharpening block to the direction of the radius of CBN grinding wheel, sharpening block grinding

grains hardness enough to remove CBN grinding particles. When the CBN abrasive grains meet the sharpening block abrasive grains, the sharpening block abrasive grains

will break due to the higher hardness of CBN abrasive grains. Filling up the grinding grains in the gap of the sharpening block helps to cut the binder, thus making the

shallow grinding grains on the CBN grinding wheel fall off, achieving the purpose of sharpening.

C. Oil-stone sharpening is a widely used sharpening method, which mainly removes the bond of CBN grinding wheel through the extrusion of crushing grains in the

contact area. However, the sharpening of the oil-stone can not obtain the larger protruding height of abrasive particles, so it cannot be used for the sharpening of the CBN

grinding wheel with the large cutting amount.

To sum up, there are many shaping methods for CBN grinding wheel, among which the diamond roller shaping method is the best. The sharpening method is

characterized by avoiding the effect on CBN grinding grains and directly etching the binders. Therefore, among the various sharpening methods for CBN grinding wheels,

the free grinding grains sharpening method has a good effect but low efficiency. Therefore, in recent years, the same kind of diamond roller is often used as a tool for

shaping and sharpening. Through adjusting the process parameters, the shaping and sharpening of the ceramic CBN grinding wheel are completed by clamping once.