Ultra-thin Diamond Cutting Wheel

1. Why use diamond cutting wheel to cut carbide and zirconia ceramics

Cutting hard alloy and zirconia ceramics are very challenging work, first of all, hard alloy often used as a tool, can see the hardness of the high, the same zirconia ceramics Mohr hardness of 8.5, monoclinic crystal density of 5.85, with a very high toughness and hardness, ordinary resin cutting pieces can not be processed.

2. Advantages of precision ultra-thin diamond cutting wheel

Sharp cutting, high processing efficiency;

High rigidity, high strength, long service life;

Continuous cutting does not slip, does not appear the phenomenon of saw blade passivation;

High precision, can be used to cut off the precision slotting machine, the incision is smooth without breakage.

3. Types of precision ultra-thin diamond cutting wheel

Resin bond diamond cutting wheel

Good self-sharpness, sharp cutting, flexible binding agent, can improve the quality of the processed surface, mainly used for the cutting of hard alloy, but also for the opening of quartz high borosilicate glass tube, glass (tea leakage), quartz crucible groove and cut.

Metal bond diamond cutting wheel

It is mainly used for cutting zirconia ceramics, and also for cutting fuse glass tube and sapphire.

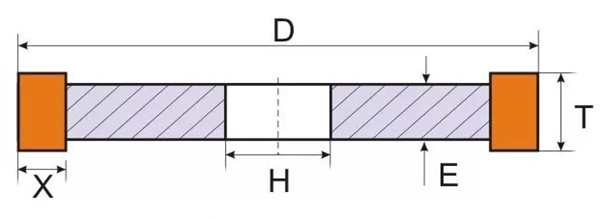

4. Shape of precision ultra-thin diamond cutting wheel

Shape 1A1 ultra-thin diamond cutting wheel

Diamond working layer and substrate thickness equal, high precision, mostly used for high-precision groove cutting and cutting.

Shape 1A1R ultra-thin diamond cutting wheel

The thickness of abrasive working layer is larger than that of substrate, which is convenient for chip removal and cooling.

Remark:

D: diameter

H: inner diameter

X: width of diamond working layer ring

E: matrix thickness

T: thickness of working layer

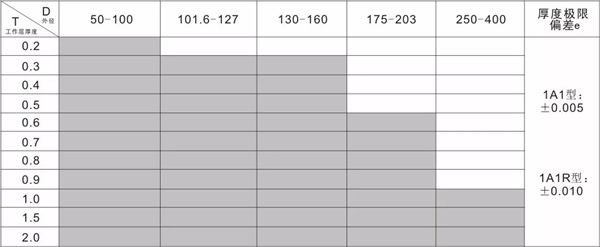

5、Precision ultra-thin diamond cutting wheel specification and precision range