Automotive engine casting aluminum alloy cylinder block processing

Automotive engine casting aluminum alloy cylinder block processing

Cylinder block is the basic part of the engine, but also the key part. The upper surface is the mounting surface of the cylinder head, the lower surface is matched with the oil pan, the front cover is the front cover, the rear is the transmission, the left and right sides are respectively the intake and exhaust surface. Cylinder block reciprocating movement of piston cylinder hole and installation of crankshaft main bearing hole, more densely covered with oil channel, channel, large and small positioning holes and threaded holes.

Cylinder hole machining is the key point of cylinder block machining, the precision of cylinder hole affects the performance of the engine, so cylinder hole machining must be careful. Cylinder hole processing technology: Boring: rough boring, fine boring –> Honing: rough honing, fine honing, platform honing.

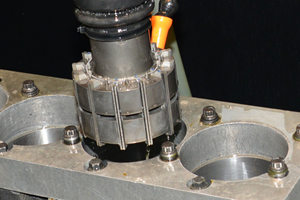

Boring:

Rough boring: Remove excess metal, eliminate cylinder hole blank error, for fine boring to establish the size precision, hole shape precision. The cubic boron nitride tool with high hardness, low friction coefficient and good wear resistance was selected for the processing allowance of about 4mm for high strength and good wear resistance of phosphorus-containing cast iron cylinder liner. The two-edged rough boring cutter removes most of the excess metal in the cylinder hole at one time, and the cutting speed reaches 200m/min.

Fine boring: To ensure high precision and stable quality of quilting, it is necessary to have proper quilting allowance and foundation precision (roundness of holes, column degree, dimensional accuracy and surface roughness). Three-edged fine boring tool, single side machining allowance is about 0.3mm, and the quilting allowance is controlled between 0.045 and 0.075mm, Tooth feed 0.2mm, cutting speed 189m/min, feed speed 510mm/min, cylinder hole cylindricity error after fine boring.

Honing:

Rough honing: Remove margin and remove fine boring marks.

Fine honing: Ensure the precision of the size and shape of the quilting to form a mesh groove.

Platform honing: Eliminate the groove peak, form the platform, establish the platform mesh structure on the surface of the cylinder hole.