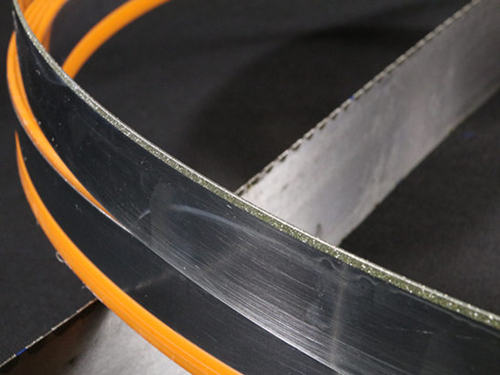

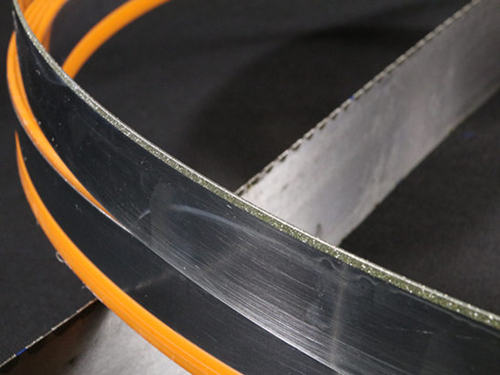

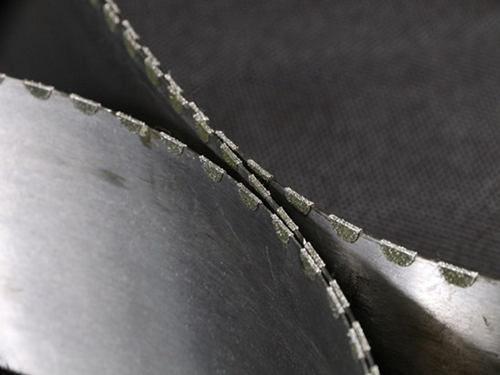

Segmented edge and continuous edge diamond coated band saw blades

Segmented edge and continuous edge diamond coated band saw blades

Diamond Band Saw Blades have proven the be an effective diamond machining tools on a large variety of materials and applications. With diamonds firmly attached to ultra-thin metal body, Diamond Band Saw Blades remain the tool of choice for many diamond cutting and machining jobs. Only the highest quality raw materials are used in the manufacturing process. Manufacturing process is carefully controlled, matching your application with the right bond type, grit size, bond hardness and composition.

Application of diamond coated band saw blades

For glass, hard graphite, high-fired graphite, ceramic, single crystal silicon ingot, synthetic quartz block and abrasive composites

Concrete materials, carbon fibre reinforced plastic, sintered materials, semiprecious gems, tile, ceramic, porcelain, marble, virgin stone

Aircraft and Sheet Stainless Steel, Aircraft Flooring and Interiors, Aluminum Oxide, Carbon, Cast Iron

Advantages of diamond coated band saw blades

Cuts safer, with snag free action, reducing the risk of breakages

Precise, smooth, clean cuts, excellent durability and fatigue resistance

Low finishing thanks to good cutting surfaces

Minimal material loss, and longer band life.

Durable steel backing material lends exceptional flexibility, while not sacrificing strength to the band saw blade

Feature of diamond coated band saw blades

Backing material made of alloyed tempering steel

The highest quality diamond grit and continuous or segmented edge.

High heat and abrasion resistance, can be used with a variety of applications.