What’s the application of CBN Wheels

CBN material is not only used for making cutting tools, but also for making CBN abrasive tools, which are used for high speed and high efficiency grinding and honing, which can greatly improve the grinding efficiency and the grinding accuracy and quality by one grade.

1. Grinding automobile parts — camshaft and crankshaft

The camshaft of automobile engine has several cams. The coarse grinding and fine grinding after quenching are the key processes that affect the CAM quality.Generally, the profile of the CAM surface is affected by the diameter of the grinding wheel, so it is difficult to ensure the accuracy of the profile of the CAM. Production practice has proved that when the diameter of the grinding wheel is large, the grinding convex wheel is thin, when the diameter of the grinding wheel is small, the grinding CAM is fat, only when the diameter of the grinding wheel is close to or equal to the diameter of the grinding wheel wheel of the cam-by-mold (generally 570mm), the profiling error is close to zero, that is, the grinding CAM surface profile curve is close to the cam-by-mold CAM. In the actual production, the diameter of the grinding wheel used is usually from D600(or 610) to D500, which is quite different from the ideal diameter of the grinding wheel (570), so the CAM curve of most camshafts always exceeds the standard in the production. To solve this problem, in the image on the CAM grinding machine using CBN grinding wheel grinding, CBN grinding wheel diameter can be made into D575, CBN abrasive layer thickness is 4 ~ 5 mm, the minimum diameter of the grinding wheel grinding is D565, grinding range although only 10 mm in diameter, but the grinding parts number is equivalent to a few pieces of grinding wheels, can not only ensure CAM curve correctly, and also won’t produce the phenomenon of grinding burn.

2. Application of CBN grinding wheel in inner hole grinding

The main reason for the low efficiency of internal grinding is the rigidity of grinding speed, material of grinding wheel and grinding rod. In the production process, the time spent in dressing and replacing the grinding wheel accounts for almost 1/3 ~ 1/5 of the working hours of a single piece. If the inside circle or groove grinding with CBN electroplated grinding wheel, and increase the grinding wheel speed, increase the stem diameter, it can improve the speed and feed rate, appropriately (arc) can not only ensure hole diameter, groove width size and shape accuracy, surface roughness and avoid burns, but also improve the machining efficiency will be multiplied, reduce the processing cost.

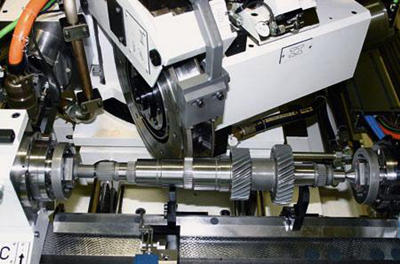

3. CBN wheel is used to grind the gear

In the past, single tooth surface grinding and multi-tooth surface grinding were used. Although single tooth surface grinding can achieve higher machining accuracy, it is of low efficiency and high cost. Although multi-tooth surface grinding has high production efficiency, its machining quality is worse than single tooth surface grinding. If CBN grinding wheel is adopted, whether single tooth surface grinding or multi-tooth surface grinding, electroplated CBN grinding wheel or ceramic bond grinding wheel is adopted for grinding, the effect is extremely significant:

(1)CBN grinding wheel can be made into a tooth shape with high precision. Due to its high durability, it is not frequently trimmed and the machine tool does not need constant adjustment, so stable tooth profile, lead and pitch precision can be obtained.

(2)high speed grinding and high feed rate can be achieved to grind the tooth surface with low roughness and no burn, and higher gear precision (grades 6 ~ 7) can be obtained under the condition of improving grinding efficiency.

(3)CBN grinding wheel has long life and good grinding performance, which saves a lot of auxiliary time such as grinding wheel dressing, machine tool adjustment and workpiece detection.

4.Use CBN abrasive tools to process hard working materials and hard working surfaces

For honing of holes of hardened steel or chilled cast iron, CBN honing stone can be used. For alloy steel, stainless steel, heat-resistant steel and alloy with high strength, high hardness and high heat sensitivity, CBN grinding wheel with high hardness and high strength should be used. Extreme pressure emulsion or high speed grinding fluid should be used for cooling.It is advisable to use CBN grinding wheel for long guide or complex surface and cam-grinding machine.