Case of CBN grinding wheel for grinding gear inner face

Vitrified CBN grinding head is the ideal tool for gear inner hole processing. The corundum grinding wheel (grinding head) is used to grind the inner hole of the gear. However, due to the high surface hardness of the gear after carburizing, the corundum grinding wheel has poor shape retention during the grinding process, and the shape needs to dressing frequently to ensure normal operation.

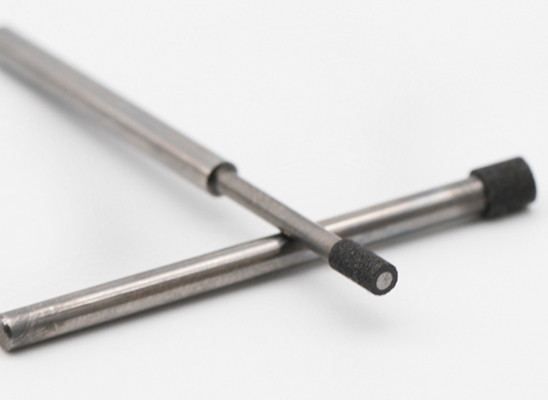

Moresuperhard recommend customer to use vitrified CBN internal grinding wheel to grind the inner hole of the gear. After mixing, mold pressing and high temperature firing, CBN raw materials have high strength, high density, sharp grinding and good shape retention, and do not need to modify the shape often. Suitable for supporting various types of CNC grinder, internal grinder or machining center. CBN grinding head in the use of high speed process is very good, on the contrary in low speed (such as line speed below 30m/s) process performance will not work well.

Gear material generally used carbon structural steel (Q255, Q275 strength high plasticity and good toughness), alloy carburizing low quenched 20MnZ, 20MnV, 20Cr, 20RcV for making small gear, quenched 20CrMn, 20CrMnTi, 20CrMnMo for making cars, motorcycles and other speed change gear, High quenched 18Cr2Ni4WA is used to make large gears such as aircraft and tanks.

After the preliminary process, the general gear needs to be treated with heat treatment or nitriding to improve the surface hardness. After treatment, the round hole above the gear will have different degrees of deformation, the amount of deformation from 0.1mm-0.5mm. At this time, it is necessary to use the internal grinder to grind the hole processing, in order to achieve the dimensional accuracy and hole inner wall finish requirements.

| Specification of customer workpiece | |

| Workpiece | Inner face of gears |

| Mateial | 20CrMnTi with carburization |

| Hardness | HRC60 |

| Grinding allowance | Unilateral 0.1-0.15mm |

| Ra require | 0.05 with like a mirror |

| Grinder RPM | 20000-30000 |

| Dressing | Stationary dresser. |

| Solution for Ra 0.05 internal grinding surface roughness | |

| Wheel size | D50xT7 |

| Wheel material | Vitrified bond CBN wheel for rough grinding and resin bond CBN wheel for fine grinding . |

| Operation | The first step removes the excess with a vitrified CBN wheel and leaves a 10-micron allowance. The second step is to use resin CBN grinding wheel for fine grinding and increase the line speed. |

If you have any requirement about gear grinding, you can contact Alan by email (alan.wang@moresuperhard.com) to contact in detail.

—EDITOR: Alan Wang/ Doris Hu

—POST;Doris Hu