CBN grinding wheel for bearing steel

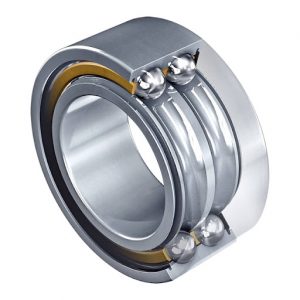

Bearing steel is the steel used to make balls, rollers and bearing rings. Bearing steel is also known as high carbon chromium steel, carbon content ω C is about 1%, chromium content ω Cr is 0.5%-1.65%. Bearing steel is divided into high carbon chromium bearing steel, chromium-free bearing steel, carburized bearing steel, stainless bearing steel, medium and high temperature bearing steel and antimagnetic bearing steel six categories.

Bearing steels have high and uniform hardness and wear resistance, as well as high elastic limits. The bearing steel has strict requirements on the uniformity of chemical composition, the content and distribution of non-metallic inclusions, and the distribution of carbides. It is one of the most strict steel types in all steel production.

Bearing steel is a kind of steel used in the manufacture of rolling bearings, such as balls, rollers and sleeves. It is also used in the manufacture of precision measuring tools, cold stamping dies, machine tool screws, such as stamping dies, measuring tools, taps and precision parts of diesel engine oil pumps. Bearing steel is the steel used to make balls, rollers and bearing rings.

Heat treatment process of bearing steel :

There are two main steps of bearing steel heat treatment process: pre-heat treatment and final heat treatment. GCr15 steel is one of the most widely used bearing steels with high carbon chromium bearing steel with less alloy content and good performance. After heat treatment, GCr15 bearing steel has high and uniform hardness, good wear resistance and high contact fatigue performance.

Anneal:

(1) complete annealing and isothermal annealing: complete annealing and weighing crystallization annealing, generally referred to as annealing, this annealing is mainly used for eutectoid components of all kinds of carbon steel and alloy steel casting, forging and hot rolled profiles, sometimes also used for welding structure. Usually as the final heat treatment of some unimportant parts, or as the pre-heat treatment of some parts.

(2) spheroidizing annealing: spheroidizing annealing is mainly used for eutectoid carbon steel and alloy tool steel (such as the steel used in manufacturing cutting tools, measuring tools and molds). Its main purpose is to reduce hardness, improve machinability, and prepare for later hardening.

Quenching:

In order to improve the hardness of the method, the main form is through heating, heat preservation, rapid cooling. The most common cooling media are brine, water and oil. Saline quenched workpiece, easy to get high hardness and smooth surface, not easy to produce hardened soft point, but easy to make the workpiece deformation serious, even cracking. Oil as quenching medium is only suitable for the quenching of some alloy steel or small size carbon steel workpiece with relatively large stability of undercooled austenite.

Tempering:

(1) Reduce brittleness, eliminate or reduce internal stress, there is a lot of internal stress and brittleness of steel after quenching, such as not tempering in time often make steel deformation and even cracking.

(2) To obtain the mechanical properties required by the workpiece, the workpiece after quenching high hardness and brittleness, in order to meet the requirements of different performance of various workpiece, can be adjusted by appropriate tempering with the hardness, reduce brittleness, get the required toughness, plasticity.

(3) Stabilize the size of the workpiece

(4) For some alloy steel that is difficult to soften by annealing, high temperature tempering is often used after quenching (or normalizing), so that the carbide in the steel is properly gathered, and the hardness is reduced to facilitate cutting.

Diamond grinding wheel is a better choice for grinding hard alloy, optical glass, ceramics, gem and stone materials with high hardness and high brittleness. However, diamond is not suitable for grinding steel because it is easy to carbonize at 700℃~800℃. The hardness of CBN is slightly inferior to diamond, but it has good thermal stability (can withstand 1300℃~1400℃ high temperature), CBN is not like diamond in high temperature, that is, oxidation and grapitization, and iron group elements chemical inertia, high thermal conductivity, with its production of grinding wheels long life (up to corundum grinding wheel dozens of times to more than 100 times), It is a better choice to replace hardened steel, high speed tool steel, bearing steel, stainless steel, heat resistant steel and titanium alloy and other metal materials with high hardness and toughness.

—EDITOR: Doris Hu

—POST: Doris Hu