-

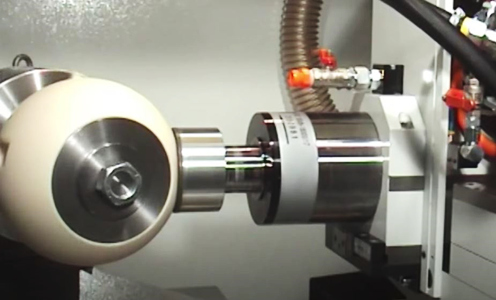

Case of ceramic femur processing customer

2024-02-03In view of the human life support properties of the required implants, the demand for The processing quality of the implant material surfaces of the smallest components is particularly stringent, especially when it comes to orthopedic implants, joint replacements and implant material surface processing applications.

Medical implants are mostly made of biocompatible materials, which are difficult to process.

For ceramic femur processing, Moresuperhard recommends using resin diamond grinding wheel for rough grinding and a resin grinding wheel for fine grinding (resin is easy to repair).

Learn More

-

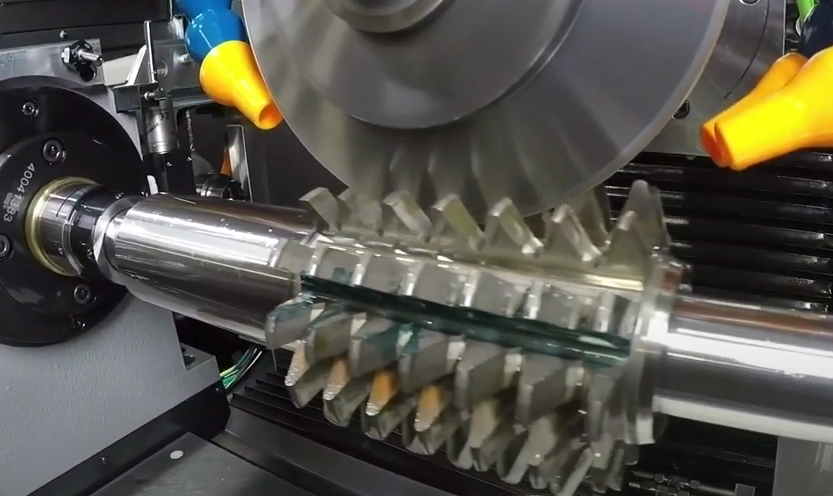

Case of metal CBN grinding wheel for gear hob cutter

2024-01-26Test feedback:

1. The grinding wheel is resistant to grinding and has one-third longer service life than its peers.

2. The grinding wheel has good self-sharpening properties, which reduces the frequency of dressing and saves time.

3. The grinding wheel has high precision and good grinding effect

4. The soft and hardness formula of the grinding wheel meets customer requirements, and there is no burn or blackening.

5. The grinding wheel consumes less and has a long service life.Learn More

-

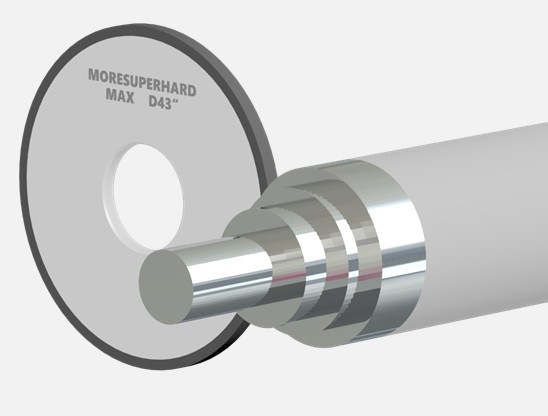

Case of resin CBN grinding wheel for metal thermal spray coating

2024-01-08Learn More

-

Case of electroplated diamond grinding wheel for PEEK

2023-12-29Learn More

-

Case of diamond grinding wheel for thermal spray coating

2023-12-27Resin diamond grinding wheel for grinding and finishing of thermal spray coatings ( including tungsten carbide , chrome carbide and chrome oxide ), ceramics, carbides, chilled iron composites and other hard-to-grind materials. Vitrified Diamond Grinding Wheel for Hard Surface in Thermal Spraying Coating

Learn More

-

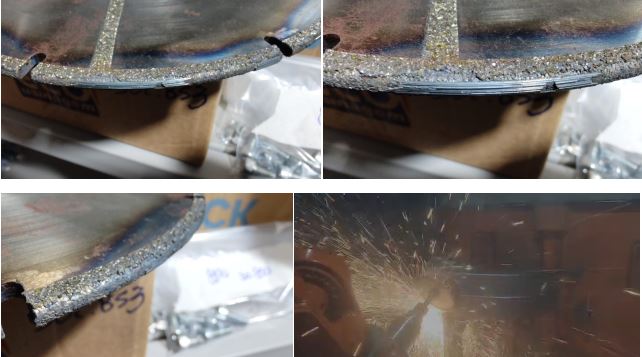

Case of metal CBN cut off wheel for SUH11 valve CBN

2023-12-09One of the key advantages of metal CBN cutting discs is their ability to deliver enhanced precision. SUH11 is a kind of heat-resistant stainless steel used in the manufacture of valves, which demands consistent and accurate machining. Metal CBN cutting discs provide a precise cutting edge that enables operators to achieve tight tolerances and maintain dimensional accuracy throughout the machining process. This level of precision is essential for ensuring the proper fit and functionality of valves.

Learn More

-

Case of internal grinding wheel for Injector

2023-11-18Moresuperhard center hole seat surface grinding CBN internal grinding wheel is suitable for center hole seat surface grinding of fuel injection nozzles. It is a high-precision grinding product used for grinding the center hole and seat surface of workpieces. The product has good grinding consistency and a processing accuracy of 2.0 Within microns, it has successfully replaced imported grinding wheels and can be customized and tested.

Learn More

-

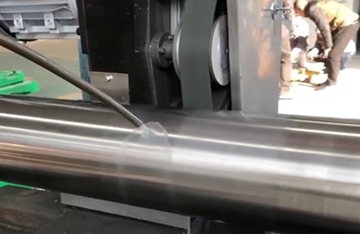

Case of electroplated diamond abrasive belt for polishing carbide coating roll

2023-11-17Diamond has a Mohs hardness of 10, making it the hardest material ever discovered. Diamond abrasive belt is especially suitable for processing non-metallic and non-ferrous metal-based materials that are difficult to process with high hardness and brittleness.

The diamond abrasive belt made by electroplating process has high bonding strength between diamond and base cloth. In addition, it adopts a gapped grinding unit arrangement, which has better chip removal and lower grinding temperature. It can not only ensure the surface quality of the workpiece, but also ensure the surface quality of the workpiece. It can also ensure the intrinsic quality of the workpiece, thereby improving the fatigue strength of the parts, extending their service life and improving production efficiency. The grinding process of diamond abrasive belt also has the characteristics of less dust, less noise and low energy consumption, which is very energy-saving and environmentally friendly.

Learn More

-

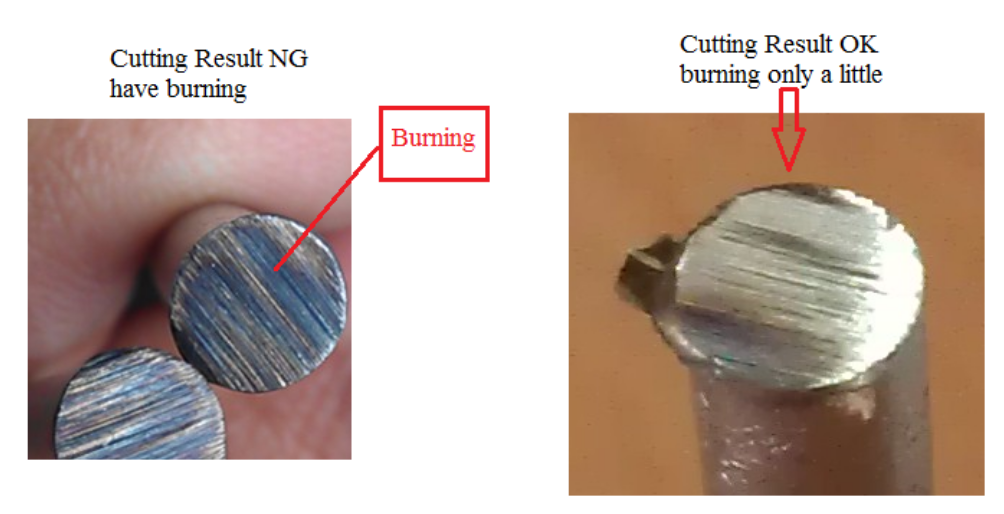

Case of grinding wheel for 38crmoal grinding

2023-11-08For 38crmoal material grinding, if workpiece with lower grinding requirements generally uses corundum grinding wheel, such as white corundum, brown corundum, single crystal corundum grinding wheel, etc., the grit size can be selected with 46#-70#. However, if you want better grinding results, it is recommended to use More Superhard ceramic/vitrified bond CBN grinding wheel.

More Superhard ceramic/vitrified bond CBN grinding wheel with good grinding efficiency, wear resistance and high speed processing without burning the workpiece characteristics, it can be use for process high hard and tough materials that are difficult to process.

Learn More

-

Case of electroplated diamond grinding wheel for cast iron

2023-10-27Moresuperhard changes the volume of diamond and the control of working layer density according to the different requirements for the surface finish of castings, and increases the grinding amount to the best state according to the needs. The maximum grinding amount can reach 3200g every ten minutes, and the sharpness changes during the service life. Too big.

Electroplated diamond grinding wheels are suitable for grinding, deburring and polishing ferrous metals: cast steel, cast iron, non-ferrous metals: cast aluminum alloys, aluminum-magnesium alloys. This product has high manufacturing precision, long service life, low single-piece processing cost, and It can be used under high-speed conditions, which greatly improves work efficiency. It solves the problem of grinding large workpieces (aerospace nacelles, ship hulls, wind energy blades, engine blades, composite pipes, etc.) and integrated deburring and polishing of workpieces with complex contours (various castings such as engine blocks and heads).Learn More