-

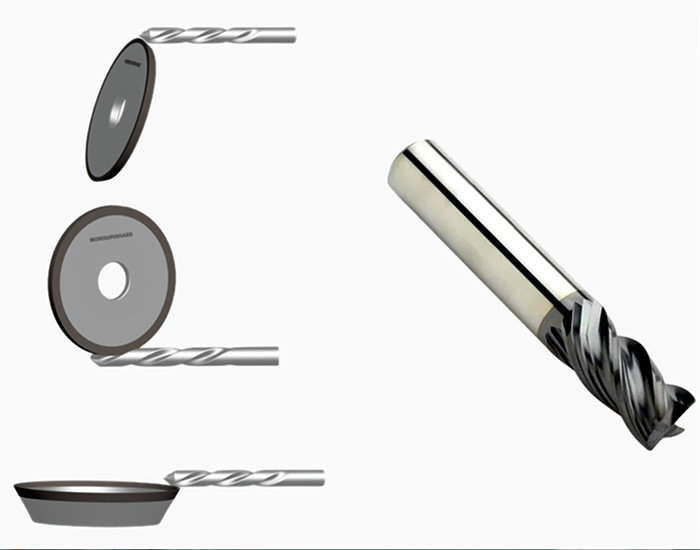

Case of resin/ hybrid diamond grinding wheel for carbide milling cutter and resharpening

2023-07-20Diamond and CBN grinding wheels always used for cutting tools production, especially resin diamond grinding wheel and hybrid diamond grinding wheel.

Learn More

-

Case of resin CBN grinding wheel for gear hob cutter

2023-07-20As the wear degree of the gear hob cutter increases during use, the cutting performance will decrease, which will increase the roughness of the machined tooth surface, increase the cutting force, and cause vibration or abnormal sound during the cutting process. If you continue to use it at this time, it will not only further deteriorate the processing quality, but also sharply wear the tool. Therefore, when the gear hob cutter itself cannot meet the process requirements, it needs to be regrinded.

Learn More

-

Good Review of resin bonded diamond grinding wheel for glass part

2023-07-14Learn More

-

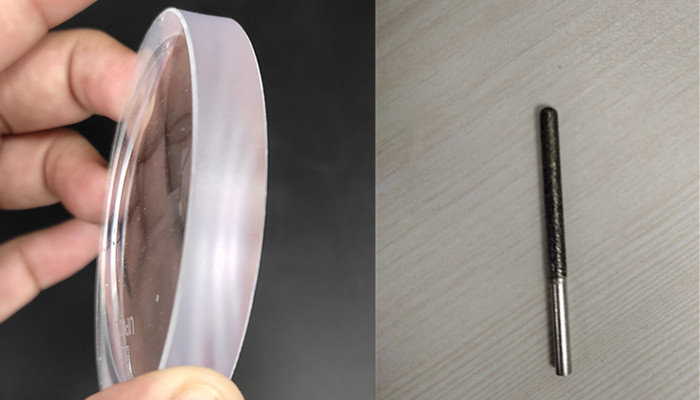

Case of electroplated CBN grinding pins for Zeiss lens edge grinding

2023-07-09Moresuerhard also provides customers with a new grinding solution, recommending electroplated diamond lenses, because the lenses are ceramics, and grinding with diamond materials is also very effective and more cost-effective.

Learn More

-

Case of metal CBN grinding wheel for engine valve

2023-07-03Learn More

-

Case of Vitrified bond CBN wheel for compressor cylinder

2023-07-01Vitrified bond CBN internal grinding wheels are widely used in air-conditioning compressors, auto parts and other industries, such as compressor pistons, cylinders, cylinder heads, bearings, gears and other internal hole grinding. CBN internal grinding wheel is suitable for various ultra-high precision internal hole grinding, the grinding wheel has an open structure and good self-sharpening.

Learn More

-

Case of resin CBN grinding wheel for HSS circular saw blade

2023-06-25Recently, we have a circular saw blade customer who mainly manufactures carbide and high-speed steel circular saw blades. The customer wants to grind the cutting edge with Moresuperhard resin diamond and resin CBN products. In addition, he also hopes to distribute some products, grinding heads. The customer want to order a resin CBN grinding head for grinding the edge of a circular saw blade of the customer. We speculate that it should be used for finish dressing.

Learn More

-

Case of resin diamond sanding belt for polishing tungsten carbide coating

2023-06-10Resin abrasive belts use resin as a binder, and also have the dual advantages of softness of traditional coated abrasives and high hardness of diamond. However, during the grinding process, heat accumulates next to the diamond. If it cannot be exported or discharged immediately, the temperature here will rise immediately, causing the binder to melt, and the diamond will fall off before it can fully function, and the service life will be short. Therefore, the diamond resin abrasive belt must be cooled with water for grinding.

Learn More

-

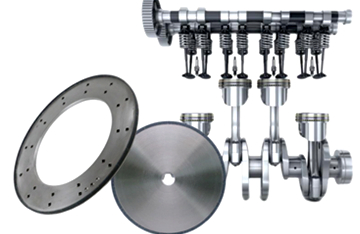

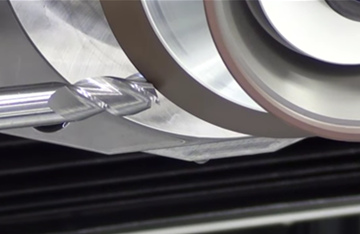

Case of vitrified CBN grinding wheel for crankshaft grinding on Landis grinder

2023-05-04The crankshaft is the main rotating part of the engine. After the connecting rod is installed, it can undertake the up and down (reciprocating) motion of the connecting rod into a circular (rotating) motion.

The crankshaft is an important part of the engine. Its material is made of carbon structural steel or ductile iron. There are two important parts: main journal, connecting rod journal (and others). The main journal is installed on the cylinder block, the connecting rod journal is connected with the large end hole of the connecting rod, and the small end hole of the connecting rod is connected with the cylinder piston, which is a typical slider crank mechanism.

Moresuperhard can make vitriied CBN grinding wheel for camshaft/crankshat grinding, all sizes can customize according to your requirement.

Learn More

-

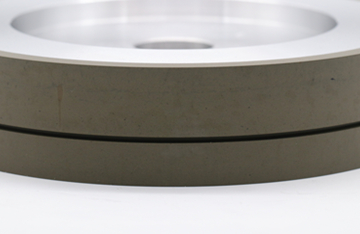

Good Feedback of CNC Grinding Wheel

2023-04-08Resin diamond grinding wheel has high hardness, high strength, and strong grinding ability. It is mainly used for grinding high and hard alloys, non-metallic materials, cutting hard and brittle cemented carbide, non-metallic minerals, etc. Such as cemented carbide, ceramics, agate, optical glass, semiconductor materials, wear-resistant cast iron, stone, Most hybrid bond grinding wheels are suitable for use with carbide (tungsten carbide) milling cutters, drills and other tools to effectively grind grooves. Then the customer mentioned two brands of grinding wheels and one brand of cutting tools.etc.

Learn More