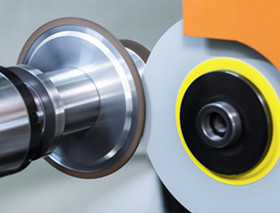

Diamond dresser for dressing aluminum oxide wheel

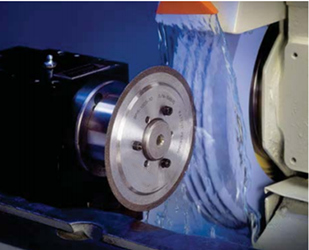

In the long grinding process of alumina grinding wheel, due to the action of grinding force and grinding temperature, the abrasive material on the working surface of the grinding wheel will gradually dull. A dull grinding wheel will affect the surface quality and geometric accuracy of the workpiece to be grinded. Therefore, the grinding wheel should be trimmed regularly after a period of use, to trim the dull place and regain the sharp surface. This can not only improve the grinding efficiency, but also ensure the grinding quality.

Diamond roller made of a large number of diamond particles embedded on the surface of a steel roller by electroplating or powder metallurgy. The diamond roller rotates at a certain speed and produces grinding and rolling effects on the surface of the high-speed rotating wheel, so that the grinding wheel can obtain a sharp working surface consistent with the profile of the roller. Dressing grinding wheel one-time forming, with high efficiency, high precision, durable characteristics, widely used in thread, gear, bearing, machine tools, automobiles, blades, cutting tools and so on.

Advantages of diamond roller dressing grinding wheel

(1) High efficiency. Simple operation, high dressing efficiency, long service life, stable quality.

(2) Precision stability. Adjustable grinding wheel with complex surface, stable surface quality and accuracy.

(3) Small tolerance. The angular symmetry tolerance of diamond dressing roller is controlled within 0.5 degree, and the minimum tolerance of arc is guaranteed within 2μm.

(4) Short time. Diamond rollers greatly shorten the dressing time, improve production efficiency and reduce the wear degree of mechanical equipment.

—EDITOR: Sarah Shi/Doris Hu

—POST:Doris Hu