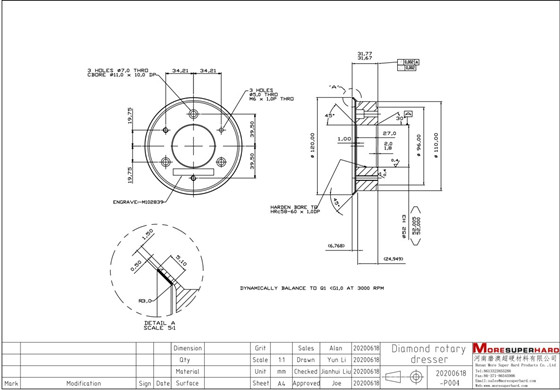

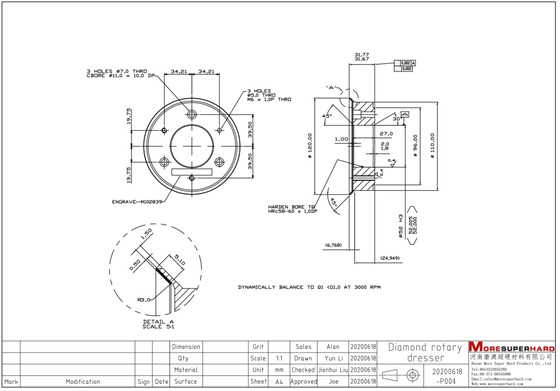

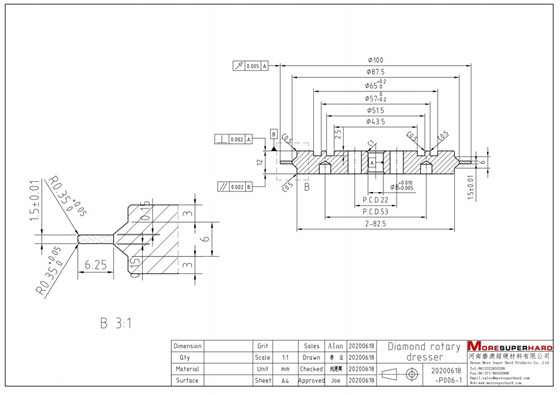

Diamond rotary dresser for crankshaft grinding wheel

1. Rotary dresser for the WA/PA wheels.

Dressing with rotating diamond tools has been found to be a reliable technique in series and performance grinding processes, especially those applications using vitrified bonded grinding wheels.

The automotive and -supply industry for grinding crankshafts.

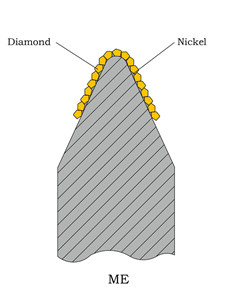

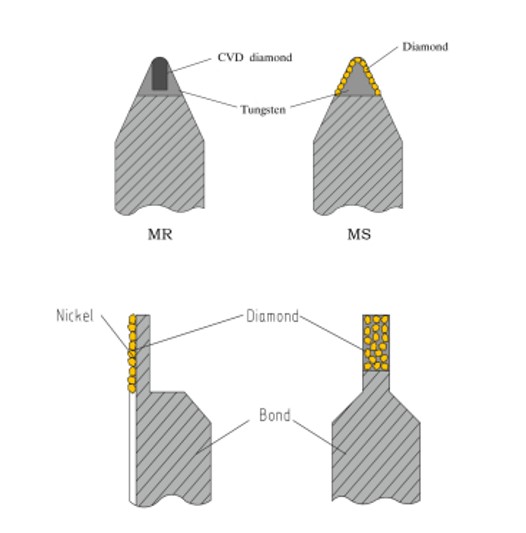

Type of diamond rolls

diamomd dresser

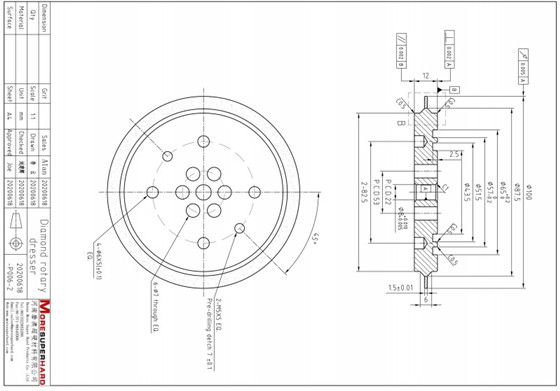

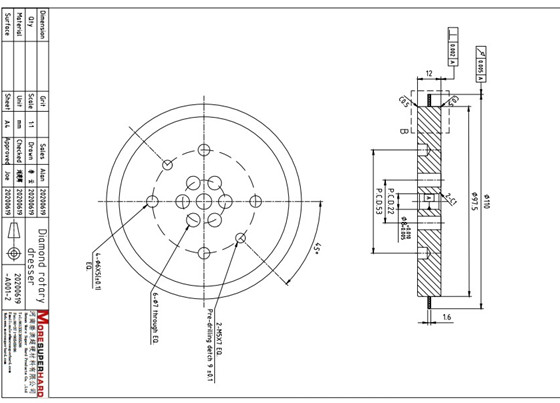

2. Rotary dresser for the Vitrified bond CBN wheels.

The primary characteristics of Vitrified CBN grinding wheel are high hardness, high thermal conductivity, high sharpness, resulting in high grinding efficiency. Suitable for high efficiency grinding of steel.

Because CBN material is hard so it is very difficult to dressing, Then special diamond rollers are needed.

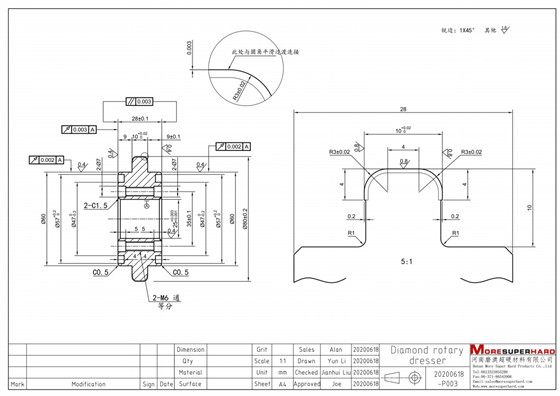

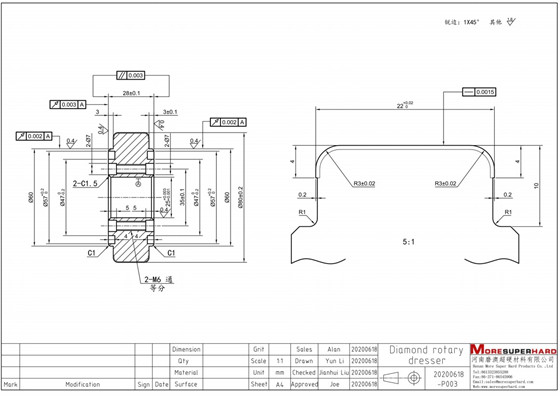

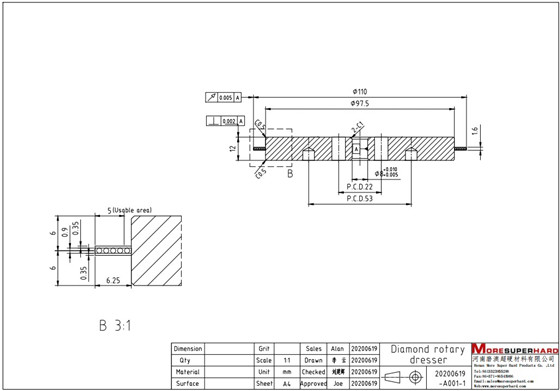

Type of diamond dresser

(1)For Junker Machine

Grinding Wheel speed when dressing:60m/s

Rotary dresser speed when dressing:120M/s

(2) For JTEKT(Toyota) Machine

Grinding Wheel speed when dressing:70m/s

Rotary dresser speed when dressing:130M/s

(3) For Landis Machine

Grinding Wheel speed when dressing:60m/s

Rotary dresser speed when dressing:120M/s

Standard Accuracy of diamond rolls

|

Measure of length

|

± 0,002 mm

|

|

Measure of step

|

± 0,002 mm

|

|

Radius (for radii < 20 mm)

|

± 0,002 mm

|

|

Angle (dependent on the side length):

|

± 1‘

|

|

Evenness

|

± 0,002 mm

|

|

Line shape

|

0,0015 mm

|

|

Concentric run-out, related to an area A:

|

0,002 mm

|

|

Cylinder shape

|

0,002 mm

|

|

Evenness, area of contact:

|

0,002 mm

|

|

Rectangularity, area of contact related to the bore:

|

0,002 mm

|

|

Axial run-out, area of contact related to the bore:

|

0,002 mm

|

|

Concentric run-out, complete profile related to the inspection collar:

|

0,002 mm

|

| Concentric run-out, diamond coating related to the bore:

|

0,003 mm

|

| Diameter of the bore:

|

Tolerance class H3

|

.jpg)