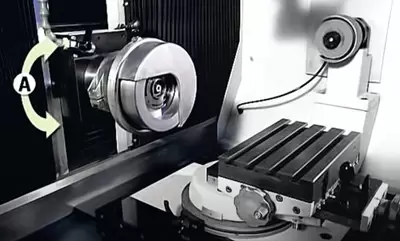

Ewag RS-15 Series Diamond Tool Grinder

The RS series manual universal grinding machine of Ewag have excellent performance in grinding superhard materials such as PCD tool edges for over 30 years. Ewag manual grinding machines are used to grind high-precision micro-tools made of carbide, steel or other materials. In addition, our machines can withstand the rational manufacturing and re-sharpening of polycrystalline diamond and carbide tools.

“Ewag’s tool grinders have proven their stability, accuracy and flexibility to the highest levels, “said ChristianMolch, managing director of technical production center in DE Pforzheim. In the German Pforzheim factory, there are 22 manual RS15 and 3 RS12 are working , usually 2 shifts per day.

When the technical production center began production in 1980, tool grinders were required to process superhard materials, and the machining tolerance had to be stable for a long time within 2um. Of course, this machine tool also needs to be extremely flexible to adapt to a variety of insert geometry and even including single efficient machining. “In retrospect, Ewag’s RS tool grinders are the only machines that meet these requirements in terms of spatial motion,” Mr. ChristianMolch emphasized.

Over the years, RS-15 series diamond tool grinders have become the first choice for grinding PCD complex cutting tools.

Abundant options and readily available add-on features enable rapid machining of complex profiles, such as convex profiles and sometimes (PCD materials are not included) concave arcs with axial angles and cutting edges. In addition, the latest version of the RS15 manual universal diamond tool grinder can quickly and easily set up and operate the machining tool. This is why Mapal continues to purchase RS15 tool grinders to accommodate a wide range of drill and hole tools, both left-handed and right-handed, with internal profiles and axial angles, cutting grooves, and PCD indexable inserts. It can be made new and re-grind. “As part of our international production strategy, we have acquired the opportunity to integrate the 500th R15 into our Mladaboreslav subsidiary in the Czech Republic.”

Although other machining technologies such as discharge machining or laser machining are increasingly available, Mapal’s tool experts believe that grinding for PCDs is essential. Based on his positive experience with hand tool grinders, Mr. Molch concluded, “In view of these advantages, when Germany needs to grind PCD tools, we will ignore the high staff cost and give priority to Ewag’s hand tool grinders.

Moresuperhard is a company committed to providing machining solutions for PCD/MCD/CVD/ND precision tools. We can provide suitable diamond wheels for EWAG RS15 and other RS series tool grinding machine. MORESUPERHAD can supply quality PCD grinding wheel at very long life as well as fast cutting. We only choose the very strong synthetic diamond as the raw materials, we make sure not only the particle shape is round enough but also be with some sharp points, which can make sure we won’t lose the efficiency while we still want enough life from the wheels. So it will help you get fast , stable, much more PCD tools in unit time. Moreover We have one series of solution on PCD&CBN tools, from the raw PCD/PCBN blanks, the PCD/CBN grinding wheel, the PCD/CBN tools grinding machine, laser cutting machine, the polishing and lapping machine & wheels, the chamfer machine &wheels, and the brazing machine include the high frequency & the vacuum brazing machine for PCD/PCBN tools.