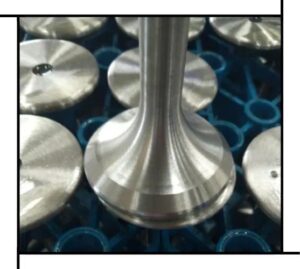

Example of New-type Six Valve Grinding

From:https://mp.weixin.qq.com/s/iqqqyUkkf1bKk6QWVJk6gw

Types of valve materials

According to the use occasion of the valve, the valve materials can be divided into the following three categories.

1) The applications in automotive gasoline engines are roughly divided into 4 types:

① For light passenger cars and trucks, 40Cr is used for intake valve and 4Cr9Si2、4Cr10Si2Mo steel is used for exhaust valve;

②Medium-sized passenger and truck, 5Cr8Si2、4Cr9Si2 is used for intake valve, 21-4N steel is used for exhaust valve;

③4Cr10Si2 Mo is used for the intake valve of low and mid-range cars, and 21-4N is used for the exhaust valve;

④ 4Cr10Si2Mo、21-4N is used for the intake valve of medium and high-end cars, and 21-4NWNb、Inconel751、Nimonic80A is used for the exhaust valve.

2) For vehicle diesel engines, 4Cr9Si2、4Cr10Si2Mo is used for the intake valve of medium-sized vehicles, XB、MF811、X85CrMoV182、21-12N,23-8N for exhaust valve; 4Cr9Si2、4Cr10Si2Mo、MF811、X85CrMoV182、MF811、X85CrMoV182、 XB, the exhaust valve uses 21-12N, 23-8N, 21-4Nb, ResisTEL.

3) 4Cr9Si2、4Cr10Si2Mo is used in the intake valve of high-speed diesel engines for locomotives and ships; exhaust valves: 4Cr14Ni14W2Mo、21-12N、LF2、LF4 for domestic locomotive diesel engines, 21-4NWNb、ResisTEL、Inconel751、Nimonic80A .

| Type | Material grade |

Heat treatment state at the time of delivery |

Hardness

HB |

Tensile strength |

| Constructional

steel |

40Cr | Anneal | ≤269 | — |

| 45Mn2 | Anneal | ≤269 | — | |

| Martensitic steel | 4Cr9Si3 | Anneal | ≤269 | — |

| 5Cr9Si3 | Anneal | ≤300 | — | |

| 5Cr8Si2 | Anneal | ≤300 | — | |

| 4Cr10Si2Mo | Anneal | ≤269 | — | |

| 8Cr20Si2Ni | Anneal | ≤300 | — | |

| 9Cr18Mo2V | Anneal | ≤300 | — | |

| Austenite steel | 4Cr14Ni14W2Mo | Solution | ≤255 | — |

| 2Cr21Ni12N | Solution | ≤209 | — | |

| 5Cr20Mr8Ni2N | Controlled cooling | ≈385 | ≈1300 | |

| 1000-1100℃ solution | ≤385 | ≤1300 | ||

| 5Cr21Mr9Ni4N | Controlled cooling | ≈385 | ≈1300 | |

| 1000-1100℃ solution | ≤385 | ≤1300 | ||

| 5Cr21Mn9Ni4Nb2WN | Controlled cooling | ≈385 | ≈1300 | |

| 1000-1100℃ solution | ≤385 | ≤1300 | ||

| 6Cr21Mn10MoVNbN | Controlled cooling | ≈385 | ≈1300 | |

| 1000-1100℃ solution | ≤385 | ≤1300 | ||

| 3Cr23Ni8Mn3N | Controlled cooling | ≈360 | ≈1250 | |

| 1000-1100℃ solution | ≤360 | ≤1200 | ||

| High-nickel alloy | GH145 | 930-1030℃ solution | ≤325 | ≤1100 |

Common failure modes in valve material processing

The grinding characteristics of valve material in grinding. The abrasive debris is easy to adhere to the surface of the grinding wheel, filling the pores between the abrasive grains, and the grinding wheel loses its grinding ability. This phenomenon is most obvious in high nickel materials, followed by austenitic stainless steel, and martensitic stainless steel is lighter. Because of its high toughness, the grinding debris is not easy to be cut away, and the abrasive grains of the grinding wheel are easy to become dull, which worsens the grinding and causes the grinding wheel to be repaired frequently. The grinding force per unit area is large, up to 68600MPa, the grinding temperature can reach 1000~1500℃, and burns are easy to occur; the surface hardening is serious, which is 1.4~2.2 times the hardness of the substrate, and the hardening depth is 0.1~0.2mm; due to stainless steel The coefficient of linear expansion is 50% larger than that of ordinary steel, causing the workpiece to be easily deformed; austenitic stainless steel is non-magnetic, and it is difficult to grind and clamp.

More Super Hard Valve Case Sharing

More Super Hard After years of research on valve materials and the accumulation of actual grinding application performance, let’s share some actual cases of processing national Emission six emission standard valves.

1. Grinding of valve head: (valve material: high nickel material)

| Product name | Rough grinding head (external circle + cone) 60° grinding wheel |

| Specifications | 510D-30T-203.2H-60° |

| Binding agent | Electroplated |

| Weight | 20-25Kg |

| Dynamic balance | ≤0.5g |

| Installation requirements | Radial runout&end runout ≤0.003mm |

| Workpiece | |

| Margin | φ0.5-1mm |

| Material | Nickel 30(High-nickel) |

| Working accuracy | Rz≤10μm |

| Other requirement | No scratches, burns, vibration marks and other defects on the surface |

| Machining effect | |

| Processing life | 100-120 thousand Pcs |

| Roughness | Rz≈5μm |

| Processing time | 10s |

| Stability | Batch processing size is stable, no need to debug |

2.Grinding of valve lock groove: (valve material: martensite/austenite)

| Products name |

Locking groove grinding wheel |

| Specifications | 400D*24T*160H |

| Binding agent | Electroplated |

| Weight | 16-20kg |

| Dynamic balance | ≤0.5g |

| Installation requirements | Radial runout&end runout ≤0.003mm |

| Workpiece | |

| Margin | φ1.2mm |

| Material | Martensitic heat resistant steel |

| Working accuracy | Ra≤0.8μm |

| Other requirement | The grinding surface has the same texture, no chatter marks, burns, and no burrs. |

| Machining effect | |

| Processing life | 120-150 thousand Pcs |

| Roughness | Ra≤0.8μm |

| Processing time | 7~8s |

| Stability | Batch processing size is stable, no need to debug |

https://www.morediamondwheel.com/products/Grinding_Wheels_for_Auto_Processing_Industry_1.html