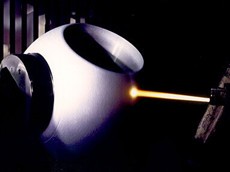

Flame spraying

Flame spraying is one of the oldest forms of thermal spray. Typically using oxygen and acetylene, these thermal spray systems melt wire or powder in the combustion stream and apply it to the part. These coatings are great for restoration of old parts. Flame spraying systems can spray I.D. and O.D. components and can be readily brought to a customer site for repairs if needed.

Process Description:An oxy-acetylene combustion process using wire based coatings

Coating Applications: Stainless Steels, Abradable coatings, Aluminum, Molybdenum, Tin, Zinc, Copper

Operating Cost Economical Spray

Bond Mechanism Mechanical: (1,000-5,000 psi)

Max Flame Temperature: 5,600 °F / 3,100 °C

Particle Velocity: 160-300 ft/sec

Max Spray Rate: 20 lb/hr (9 kg/hr)

Coating Thickness Range: 0.005″ to 0.250″

Special Features: Economical, No heat distortion

Wear Resistance: Acceptable,

Corrosion Resistance: Poor/Medium

Porosity: High