Good feedback of resin CBN grinding wheel for brake disc grinding

Resin CBN grinding wheels are indispensable tools in the automotive industry, specifically engineered for the precision grinding of brake discs. Moresuperhard offers specialized resin CBN wheels tailored for brake disc applications, ensuring high efficiency and superior performance in both manufacturing and maintenance processes.

Understanding Brake Discs

Brake discs, commonly known as rotors, are critical components of a vehicle’s braking system. They are typically made from cast iron or high-strength steel and function by providing a surface for brake pads to clamp onto, thereby slowing down or stopping the vehicle. The effectiveness of a brake disc directly influences the safety and performance of the vehicle, making its quality and maintenance paramount.

Why Do Brake Discs Require Grinding?

Over time, brake discs are subjected to wear and tear, leading to issues such as surface irregularities, grooves, and rust. Grinding is a crucial maintenance process that addresses these problems by:

-

Restoring Surface Flatness: Grinding removes high spots and surface defects, ensuring the disc is perfectly flat. This uniformity is essential for consistent braking performance and to prevent vibrations.

-

Eliminating Grooves and Imperfections: Continuous contact with brake pads can create grooves on the disc surface. Grinding smooths out these imperfections, enhancing the contact area between the disc and pads.

-

Removing Rust and Corrosion: Exposure to environmental elements can cause rust formation on brake discs. Grinding effectively cleans the surface, removing rust and preventing further corrosion.

-

Enhancing Frictional Properties: A smooth and clean disc surface improves the friction coefficient between the disc and brake pads, leading to more efficient braking.

The Role of Resin CBN Grinding Wheels in Brake Disc Maintenance

Cubic Boron Nitride (CBN) is a superabrasive material renowned for its hardness and thermal stability, making it ideal for grinding ferrous materials like brake discs. When combined with a resin bond, CBN grinding wheels offer several advantages:

-

High Grinding Efficiency: Resin CBN wheels provide rapid material removal rates, reducing processing time.

-

Superior Surface Finish: The self-sharpening nature of resin bonds ensures a consistent and smooth surface finish on the brake disc.

-

Extended Wheel Life: The durability of CBN combined with the resilience of resin bonds results in a longer-lasting grinding wheel, minimizing the need for frequent replacements.

-

Reduced Heat Generation: Efficient grinding with resin CBN wheels generates less heat, preventing thermal damage to the brake disc and preserving its metallurgical integrity.

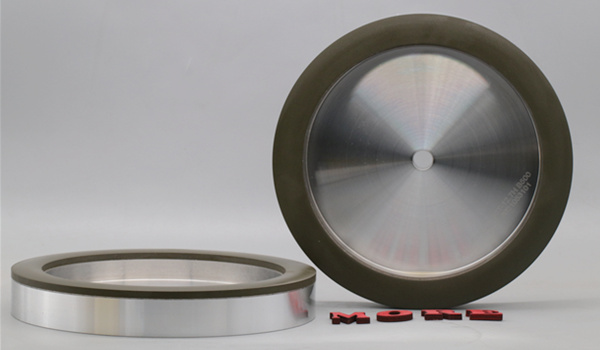

Moresuperhard Resin CBN Wheels for Brake Discs

Moresuperhard specializes in the production of high-quality resin CBN grinding wheels designed explicitly for brake disc applications. Key features of their products include:

-

Customized Specifications: Moresuperhard offers a range of sizes and grit options to meet specific grinding requirements, ensuring compatibility with various grinding machines and processes.

-

Enhanced Performance: Their resin CBN wheels are engineered to provide optimal balance between cutting efficiency and surface finish, catering to both rough grinding and fine finishing needs.

- Application Versatility: Suitable for grinding various types of brake discs, including those made from cast iron and high-strength steel, as well as coated or treated discs.

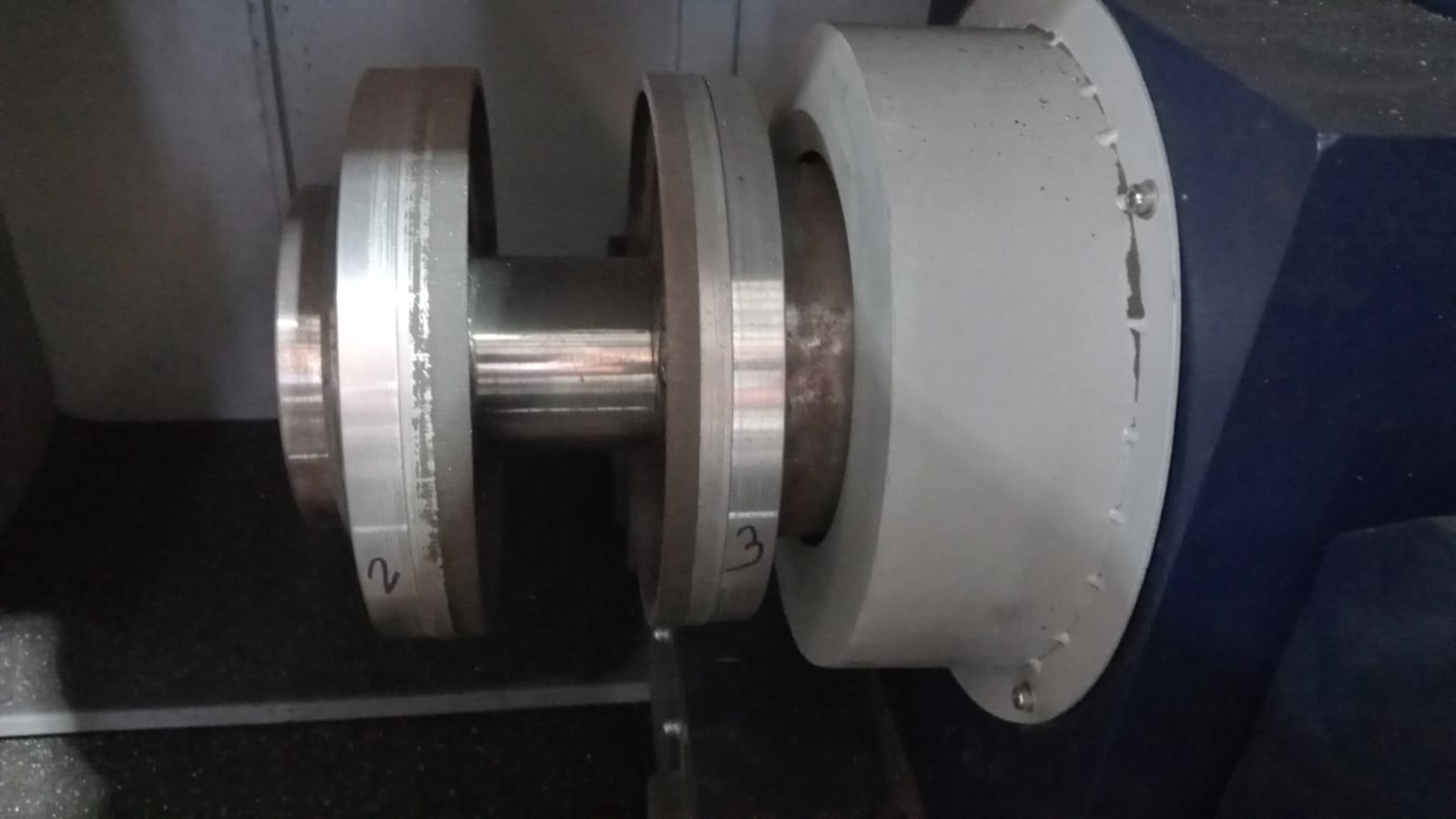

Recently Moresuperhard received good review from customers, who ordered resin CBN grinding wheel for grinding brake disc, lets see it together:

| Grinding wheel | Resin bond cbn wheels |

| Application | grinding of brake disc |

| Workpiece material | FG 260 gray cast iron, CI CASTING |

| Grit | Ra1.2-1.5, 80# |

| Size of resin CBN wheel | D200xH42xt40xW10xX10 |

Conclusion

The maintenance of brake discs is vital for vehicle safety and performance. Utilizing high-quality resin CBN grinding wheels, such as those offered by Moresuperhard, ensures efficient and precise grinding operations. By restoring the optimal condition of brake discs, these grinding wheels play a crucial role in extending the lifespan of braking systems and enhancing overall driving safety.

—EDITOR: Doris Hu, Anna Wang

—POST: Doris Hu