Grinding problems for the glass industry

The edge grinding process can effectively improve the brittleness of the glass, making the glass more beautiful and safer. Generally speaking, it is enough to use a coarse grinding wheel to grind off the corners of the glass. However, the requirements for craft decorations are higher and require rough grinding and fine grinding to make the original glass of different shapes and sizes gradually close to the workpiece required by the customer. size and surface roughness

What is the function of glass edge grinding?

After the original glass is produced, the edges of the glass are very sharp and generally need to be edged. After the glass is edged, it can play the following roles:

- Grind off the sharp edges and corners caused during cutting to prevent scratches during use.

- The small cracks and microcracks formed by cutting on the edges of the original glass are ground away, eliminating local stress concentration and increasing the strength of the glass.

- The geometric dimensional tolerance of the glass after edge grinding meets the requirements.

- Carry out different levels of quality processing on the glass edge, that is, grind it into rough grinding, fine grinding and polishing.

Common defects

1. Edge collapse

The causes of edge chipping defects include: too fast grinding speed; limited quality of the grinding wheel; improper adjustment of the grinding wheel position; poor cooling water quality or too low water pressure; the newly replaced grinding wheel is not sharpened; the original chip itself chipped; and the grinding wheel is severely worn. ;The motor vibrates too much.

Corresponding solutions include: reduce the grinding speed and improve the grinding wheel process; re-adjust the position of the grinding wheel; replace the cooling water and check the water path; reduce the grinding speed or use waste glass to open the front; replace the original piece to prevent the inflow of unqualified original pieces; Replace grinding wheel; tighten screws.

2. Corner collapse

The causes of glass chipping include insufficient parameter adjustment, causing the chamfering action to hit the corner too fast, the chamfering wheel to be a new chamfering wheel, the chamfering shaft to be severely worn, and the position of the chamfering wheel to be offset.

Corresponding solutions include: adjusting parameters according to the actual situation; using waste glass to open the chamfering wheel; replacing the shaft; adjusting the position of the chamfering wheel up and down.

3. Glass scratches

Pictures of glass scratches are shown in the figure. The causes of glass scratches include scratches on the original film; scratches during the loading process; scratches on transfer; scratches on the cleaning machine; and finally, irregularities in loading or unloading movements.

The corresponding solutions are: check the original film to see if there are scratches on the original film; check whether there are foreign objects on the film loading table or whether the film loading movement is normal; when lifting the film, the movements of both sides are coordinated.

4. Bright edge

The causes of bright edges include uneven distribution of the grinding amount of the grinding wheel, too small transmission pressure, the feed end of the edge grinding machine is not in a straight line, and the diagonal difference is too large, etc.

Corresponding solutions: 1. Re-adjust the grinding amount of the grinding wheel; 2. Adjust the tightness of the compression belt; 3. Re-adjust the feed end of the edge grinder; finally, adjust the diagonal.

5. Focused edge

When the glass comes into contact with the grinding wheel during the edge grinding process, the high-speed operation of the grinding wheel generates high temperatures. If the cooling water is insufficient, the edge of the glass will be burned and blackened, which is called burnt edge in industry terms. The causes of burnt edge include insufficient cooling water of the grinding wheel, too fast transmission speed, and excessive grinding amount on one side.

The corresponding solution is to check whether the cooling water pipe is smooth, reduce the transmission speed, and reduce the grinding amount (according to operating requirements: the grinding amount on one side shall not exceed 2.5mm).

6. Big and small heads

The big and small head means that the sizes of the two parallel sides are not the same, and the ground glass becomes an isosceles trapezoid. The reason for the large and small head is firstly that the amount of grinding on both sides of the grinding wheel is asymmetrical, causing the glass to skew during travel; secondly, the belt is not tightly pressed; thirdly, there is a gap in the transmission gear of the edge grinding machine, causing the glass position to deviate.

Corresponding solutions:

1. Readjust the grinding amount of the grinding wheel;

2. Adjust the tightness of the compression belt;

3. Adjust the transmission gear position.

4. Dimensional deviation

The reasons why the width displayed by the machine does not match the actual size of the glass grinded are: because the opening and closing transmission screw rod has been worn for a long time and there is a gap, the prepared grinding wheel will have certain changes after a period of grinding, and the pressure Insufficient belt pressing force, incorrect dimension input, and inconsistent distance between the fixed-side stop wheel and the conveyor belt, that is, inaccurate positioning of the glass, result in uneven grinding of both sides of the glass, resulting in diagonal instability and deviations.

Corresponding solutions:

1. Check the dimensions and correct the deviation; secondly, adjust the height of the pressing belt;

2. Carefully check the entered size;

3. Adjust the distance to the specified size.

4. Diagonal deviation

The diagonal deviation is due to the difference in the speed of the two lower surface conveyor belts of the conveyor system, or the grinding amount of 1#2#3# diamond wheels is inappropriate and the grinding force is uneven; Thirdly, the glass clamping force is inappropriate;

Finally, the stop blocks on the dynamic and static sides are not in a straight line or are not perpendicular to the conveyor synchronous belt.

Corresponding solutions include adjusting the belt tension, adjusting the grinding amount of the diamond wheel, adjusting the clamping force; adjusting the stops on the dynamic and static sides so that they are in a straight line and perpendicular to the conveyor synchronous belt.

Commonly used types of glass edge grinding machines

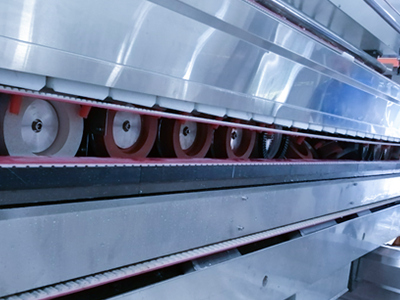

2. Linear edge grinding machine: used for grinding and polishing the edges of flat glass, usually with automatic feeding and automatic switching

3. Curved edge grinding machine: Mainly used for grinding glass edges with larger arcs, such as glass crystal balls, etc. Its processing method is similar to cutting processing.4

4. Desktop edge grinding machine: commonly used to process the edges of large glass plates, it can perform a variety of processing, such as chamfering and polishing.Light, drilling, etc.

5. CNC edging machine: controlled by CNC technology, it can achieve precision processing of flat and curved glass work.

6. Rectangular edge grinding machine: Mainly used to process the edges of irregular glass, such as car rearview mirror glass, creative home glass, etc.

7. Water jet edge grinding machine: Using high-pressure water flow for glass edge processing can make the grinding more precise and more environmentally friendly.

Common glass types and uses

Ordinary glass:

Ordinary glass is a common construction and decorative material used to make glass windows, glass doors, Glass curtain wall, furniture glass, etc.

Optical glass

Optical glass is a special kind of glass used to manufacture optical devices, such as optical lenses, optical prisms, telescopes, microscopes, etc.

Photovoltaic glass: Photovoltaic glass is a special kind of glass used in the manufacture of solar panels and solar crystalline silicon. It requires high light transmittance and low light reflectivity, as well as anti-reflection, ultraviolet protection and shock absorption. etc. performance.

Cover glass

Cover glass is a kind of glass used for mobile electronic devices, such as mobile phone glass, tablet computer glass, smart watch glass, etc. It needs to have high strength, wear resistance and anti-pollution properties.

Automobile glass:

Automobile glass is usually divided into front windshield glass, rearview mirror glass and side window glass, etc. It needs to have high transparency, good impact resistance, UV protection and heat insulation properties.

Special glass: There are many types of special glass, including fluorescent glass, ceramic glass, glass for night vision instruments, etc.

Various varieties and uses. For example, fluorescent glass is used to make fluorescent signs and fluorescent lampshades, and ceramic glass is commonly used to make stoves and detergent bottles.

Case analysis of glass edge grinding problem

1. Glass cracking problem: During the glass edge grinding process, if the processing intensity or processing speed is too high, or there are hidden surface defects, it may cause glass cracking. Solutions include selecting appropriate grinding tools and grinding parameters, regular maintenance and upkeep of equipment, and avoiding defects on the glass surface

2. Surface defects such as wear marks and burrs: If inappropriate grinding tools or improper processing parameters are used, surface defects such as wear marks and burrs will appear on the glass surface. Solutions include optimizing processing parameters, regularly replacing grinding tools, and strengthening equipment maintenance and upkeep.

3. Insufficient precision problem: Insufficient precision means that production requirements cannot be met. Solutions include using higher-precision grinding tools and equipment, and strengthening the control and optimization of processing processes.

4. Cover glass processing technology issues, how to choose grinding wheels, grinding wheels and other abrasive tools: Cover glass processing requires the selection of grinding wheels, grinding wheels and other abrasive tools with appropriate grinding grains, and reasonable selection according to specific processing requirements. Proportioning to ensure processing quality and efficiency

5. Problems with defective items in glass processing, how to avoid surface defects such as wear marks and burrs: Avoiding surface defects requires good equipment maintenance and upkeep, strengthening the control and optimization of the processing technology, and Choose suitable abrasive tools for processing

6. Glass cracking problem,

causes and solutions:

There are usually two main reasons for glass cracking problem: excessive processing intensity or processing speed, or hidden surface defects. Solutions include optimizing processing parameters, regular replacement of grinding tools, maintenance and upkeep of equipment, and selection of high-quality glass raw materials.

Glass edge grinding machine is mainly suitable for processing furniture glass, architectural glass and craft glass. It is one of the cold processing equipment that was produced earlier and has a larger usage among glass mechanical deep processing equipment. Mainly used for grinding and polishing the bottom edge and chamfering of ordinary flat glass. Generally, there are manual, digital display control, PLC computer control and other configurations.

The glass edge grinding machine has three characteristics:

First, it has a relatively single use and can only grind various straight edges;

Second, continuous grinding is possible and production efficiency is high;

Third, it can grind larger flat glass.

Glass edging machines are mainly divided into: glass linear edging machines (glass straight edging machines), glass linear beveling machines (glass beveling machines), glass linear round edging machines (round edging machines), and glass special-shaped edging machines.

- The straight edge machine is used for grinding and polishing the bottom edge and edges of flat glass.

- The beveling machine is mainly used to process the straight bevel and round bottom edge of flat glass.

- The rounding machine is used to grind the straight round edges, duckbill edges, etc. of flat glass.

- Glass special-shaped edge grinding machine is used to grind round and some special-shaped flat glass.

More SuperHard has been in glass field for more than 10 years and supplies complete processing solutions for furniture and architecture glass. We manufacture Glass Grinding and Polishing Wheels available for use on double straight-line edging machines, bevelling machines, high-speed seaming machines, Profiling machines etc.

More Superhard can produce:

Rough Grinding: Metal bond, diamond cup wheel, Diamond profile wheels

Fine Grinding: Resin bond, diamond wheel for Edging, for Bevelling

Polishing: X3000, X5000,10s,BD,BK,CE3 and felt polishing wheels

—EDITOR: Doris Hu

—POST: Doris Hu