Grinding Wheel for Automobile Crankshaft

From February 26th to March 1st, the four-day’s CME has an exhibition area of 90,000 square meters. It has five functional exhibition areas including metal cutting machine tools, metal forming machine tools, cutting tools, smart factories and international brands. Makino, Mitsubishi and THK Doosan, FANUC, Jinshang, Baichao Di, Hyundai WIA, Aachen, Shangyin, Lili, Gaofeng, Citizen, Jinyan and other more than 1,000 well-known brand companies from all over the world participated in the exhibition, showing the whole world The latest equipment and cutting-edge technology.

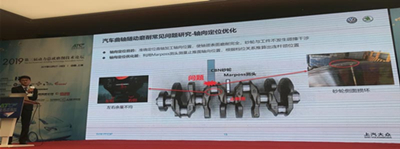

What is the crankshaft?

The main rotating mechanism of the engine, after the connecting rod is installed, can take up and down (reciprocating) movement of the connecting rod into a cyclic (rotating) motion. It is an important part of the engine. Its material is made of carbon structural steel or ductile iron. It has two important parts: the main journal, the connecting rod neck, and (among others).

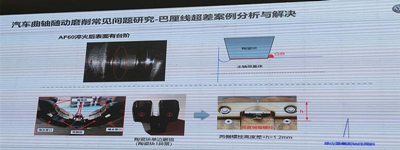

Process Analysis – When grinding the quenched steel crankshaft thrust surface, the following three types of burns may occur

*Tempering burn: If the temperature of the grinding zone does not exceed the phase transition temperature of the hardened steel, but exceeds the transformation temperature of the martensite, the tempered martensite structure of the surface metal of the thrust surface will be converted into a tempering with lower hardness. Tissue (Sorst or orthodont), this burn is called temper burn.

*Quenching burn: In addition to the quenching effect of the coolant, the surface metal is quenched twice, causing the surface metal to have a secondary quenched martensite structure, the hardness of which is higher than that of the original tempered martensite, in its lower layer, due to cooling Slower, there is a tempering structure with a lower hardness than the original tempered martensite. This type of burn is called quenching burn.

Annealing burn: If the temperature of the grinding zone exceeds the phase transition temperature, and no coolant enters in the grinding zone, the surface metal will produce annealed structure, and the surface hardness will drop sharply. This burn is called annealing burn. In the crankshaft forming grinding, it is mostly such a burn.

Crankshaft grinding wheel

Vitrified CBN grinding wheel is used for grinding the end face, piston ring, gasket, filling piece, compressor part, semiconductor material, magnetic material, cutter, the stator of vane pump, rotor, blade end, precision spring, etc.

The crankshaft grinding process is a subdivision of external cylindrical plunge grinding. In this application, both the journals and pins are ground to size. The pin bearings are generally ground with a single grinding wheel. This is used to machine the individual pin bearings in sequence. As the journals are all located on one axis, these can be machined in a single pass with a set of grinding wheels