How to process screw tap?

What is screw tap?

A screw tap is a tool for processing internal threads. According to the shape, it can be divided into spiral flute screw taps, edge angle screw taps, straight flute screw taps, and pipe thread screw taps. According to the use environment, it can be divided into hand screw taps and machine screw taps. According to specifications, it can be divided into For metric, American, and imperial screw taps, etc.

A tool for machining internal threads, with grooves along the axial direction. Also called screw screw screw tap. screw taps are divided into straight flute screw taps, spiral flute screw taps and spiral point screw taps (point screw taps) according to their shape. Straight groove screw taps are easy to process, with slightly lower precision and higher output. It is generally used for thread processing of ordinary lathes, drilling machines and screw tapping machines, and the cutting speed is relatively slow. Spiral flute screw taps are mostly used for drilling blind holes in CNC machining centers, with fast processing speed, high precision, good chip removal and good alignment. There is a flute at the front of the spiral point screw tap, which is used for the processing of through holes. Most of the screw taps provided by the tool factory are coated screw taps, which have greatly improved service life and cutting performance compared with uncoated screw taps. The cutting load distribution of screw taps with unequal diameter is reasonable, and the processing quality is high, but the manufacturing cost is also high. Trapezoidal thread screw taps are often designed with unequal diameters.

Machine and hand screw taps are the standard screw taps for cutting common threads. It is customary in China to call the high-speed steel molar screw screw taps with high manufacturing precision as machine screw screw taps, and the rolling (or incisor) screw screw taps of carbon tool steel or alloy tool steel as hand screw screw taps. In fact, the structures of the two are similar The working principle is basically the same. Generally, a screw tap consists of a working part and a shank. The working part is divided into a cutting part and a calibration part. The former is ground with a cutting cone for cutting work, and the latter is used to calibrate the size and shape of the thread.

In general, just as cemented carbide tools gradually replace high-speed steel tools in turning, cemented carbide screw taps are also used more for threaded hole processing. Compared with high-speed steel, cemented carbide has high hardness and high brittleness. Alloy screw tap screw tapping has the problem of chip handling. Even so, cemented carbide screw taps are very effective for processing cast iron and aluminum alloy materials, and the main form of screw tap damage is mechanical wear.

Classification of screw taps:

1. According to different drivers: hand screw taps and machine screw taps

2. According to the processing method: cutting screw tapand extrusion screw tap

3. According to the thread to be processed: metric coarse thread screw taps, metric fine thread screw taps, pipe thread screw taps, etc.

4. According to its shape, it is divided into straight flute screw taps, spiral flute screw taps and spiral point screw taps.

5. According to the screw tapping direction of the screw taps, they can be divided into straight screw taps and reverse screw taps.

Straight flute screw tap

Straight flute screw taps have the best versatility and the strongest rigidity. Therefore, straight flute screw taps are generally preferred when processing materials with higher hardness (such as: hardened steel above 40HRC) and chips that are in the form of powder particles (such as cast iron and cast aluminum).

Spiral flute screw tap

Spiral flute screw taps are more suitable for processing non-through hole threads (also called blind holes), and chips are discharged upward during processing. Due to the helix angle, the actual cutting rake angle of the screw tap will increase with the increase of the helix angle. Experience tells us that when processing materials with high hardness, the helix angle should be selected smaller, generally around 30 degrees, to ensure its own rigidity and to prolong the life of the screw tap. When processing non-ferrous metals such as copper, aluminum, magnesium, and zinc, which are not very hard materials, the helix angle should be selected larger, which can be around 45 degrees, and the cutting should be sharper, which is conducive to chip removal.

Angle screw tap

Chips are discharged forward when processing threads, and through-hole threads should preferably use edge angle screw taps. Since its design is based on the straight fluted screw tap, a hole is cut obliquely with a grinding wheel at the tip of the blade, so its rigidity is comparable to that of the straight fluted screw tap.

Extrusion screw tap

Different from the previous three types of cutting screw taps, the processing method of the extruding screw tap is to extrude the shape of the internal thread in the bottom hole by extrusion molding through the plastic deformation of the material itself. Therefore, the processed material should not be too hard. Its advantage is that it does not produce chips, which can eliminate 90% of machining problems. However, because it is extruded, there are fine grooves on the top of the processed internal thread, so it is not suitable for jobs with high airtightness requirements.

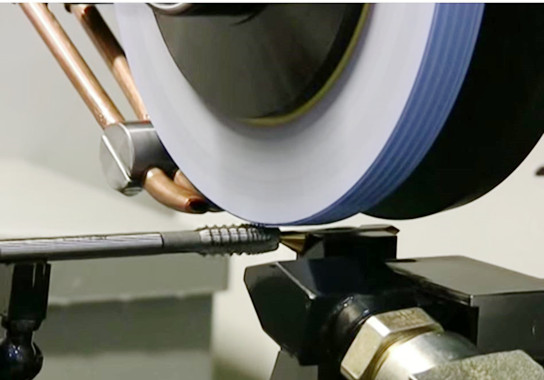

Thread grinding

Mainly used on thread grinding machines to process precision threads of hardened workpieces.

According to the shape of the cross-section of the grinding wheel, thread grinding can be divided into two types: single-line grinding wheel and multi-line grinding wheel. The pitch accuracy of the single-line grinding wheel grinding can be 5~6, the surface roughness is R1.25~0.08 microns, and the dressing of the grinding wheel is more convenient.

This method is suitable for grinding precision lead screws, thread gauges, worms, small batches of threaded workpieces and relief grinding precision hobs. Multi-line grinding wheel grinding is divided into two types: longitudinal grinding method and plunge grinding method. In the longitudinal grinding method, the width of the grinding wheel is smaller than the length of the thread to be ground, and the grinding wheel moves longitudinally once or several times to reverse the thread and grind to the final size. In the cut-in grinding method, the width of the grinding wheel is greater than the length of the thread to be ground. The grinding wheel cuts into the surface of the workpiece radially, and the workpiece can be ground after about 1.25 revolutions. The productivity is high, but the precision is slightly lower, and the dressing of the grinding wheel is more complicated. The plunge grinding method is suitable for relief grinding taps with large batches and grinding some threads for fastening.

—EDITOR: Doris Hu

—POST: Doris Hu