How to solve the white edge of glass grinding?

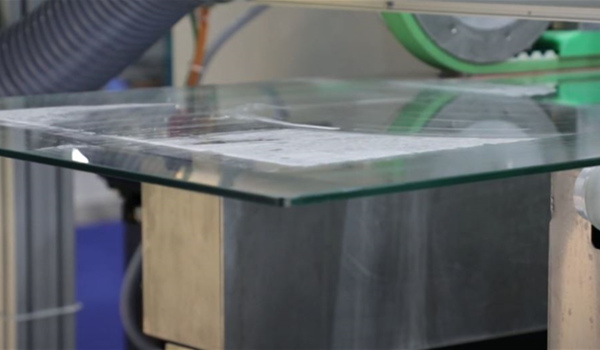

The edge grinding process can effectively improve the brittleness of the glass, making the glass more beautiful and safer. Generally speaking, it is enough to use a coarse grinding wheel to grind off the corners of the glass. However, the requirements for craft decorations are higher and require rough grinding and fine grinding to make the original glass of different shapes and sizes gradually close to the workpiece required by the customer. Size and surface roughness.

After the original glass is produced, the edges of the glass are very sharp and generally need to be edged. After the glass is edged, it can play the following roles:

1. Grind off the sharp edges and corners caused during cutting to prevent scratches during use.

2. The small cracks and microcracks formed by cutting on the edges of the original glass are ground away, eliminating local stress concentration and increasing the strength of the glass.

3. The geometric dimensional tolerance of the glass after edge grinding meets the requirements.

4. Carry out different levels of quality processing on the glass edge, that is, grind it into rough grinding, fine grinding and polishing.

Glass edge grinding method:

First use a metal-bonded diamond grinding wheel to grind, and use coarse, medium, and fine grit in order. It is normal for chipping to occur. Then use resin bonded diamond grinding wheel is ground into a frosted surface without chipping. Normally, it can be used after this.

Sometimes you want the edge to be polished like a mirror. This requires the use of a polishing wheel. Instead of diamond, use low-hardness polishing abrasives such as iron oxide and cerium oxide.

In the second step, if you use 300# for water grinding, it will basically be almost translucent.

Precautions for glass edge grinding

1. Edge grinding operators must wear protective equipment, gloves, and rubber before going to work. When grinding large pieces of glass, they must wear safety helmets. Read the production task order carefully.

2. Before processing, it is necessary to carefully recheck the dimensions of the semi-finished product to avoid continuation of errors in the previous process, and check the appearance quality of the glass to avoid scratches and scales, missing corners, etc. that cannot be cleaned by grinding.

3. During inspection, pay attention to whether the semi-finished product can be processed on the glass. If there are cracks, edge grinding cannot be performed to avoid damage to equipment and personnel.

4. To remove the glass, you must lift it from the outside to the inside, and you cannot remove any piece of glass inside.

5. For fine glass with high requirements on appearance quality, the appearance quality inspection should exceed or be equivalent to the quality and appearance requirements of automotive grade original glass.

6. Grinding amount control: grinding amount below 8mm﹤2.5mm, grinding amount below 10-19mm﹤1.5mm; feed speed: speed below 8mm﹤2.5m, speed 10-19mm﹤1.5m.

7. After the edge grinding machine is started and stopped every day, the operator must perform routine inspections. The inspections include whether the grinding wheel is loose, the degree of wear, whether the circulating water is clean, etc. When grinding glass of different thicknesses, trial grinding must be performed.

8. When grinding large sheets of glass with a layout exceeding 3 square meters, lifting hooks and suction cups must be used. Multiple people cannot run when lifting the glass onto the edge grinding machine, and the walking steps must be consistent.

9. The grinding wheel should be inspected, adjusted, and calibrated every day. The circulating water should be kept clean, the circulating pipe should be kept smooth, and the water must be changed frequently.

10. The replacement grinding wheel must be sharpened before the product can be processed.

How to solve the white edge of glass grinding?

1. Grinding mechanical problems:grinding machine wear serious, insufficient pressure and other problems will affect the grinding quality, resulting in glass white edge.

2. Inappropriate edge grinding wheel: When selecting edge grinding wheel,it is necessary according to the type or thickness or grinding method of glass to choose suitable edge grinding wheel, otherwise it will lead to the wheel and glass do not match, resulting in white glass edge.

3. Grinding fluid pollution: If the grinding fluid is not clean, the impurities and dirt will rub with the grinding wheel to produce scratches, resulting in the glass grinding edge is not smoothand white phenomenon.

4. Insufficient grinding times: glass requires a certain number of grinding times to achieve the desired grinding effect. If the number is not enough, the burrs and cracks on the grinding surface are not removed, which will also lead to white glass grinding edges.

4. Improper operation: If the worker does not grasp the grinding posture, strength and speed during the operation, it will lead to irregular grinding marks on the glass grinding surface.

Moresuperhard metal bond glass edging wheel has been continuously improved to solve the problem of white glass for many customers. The glass edges and corners are smooth without breakage and white edges.

—EDITOR: Doris Hu, Anna Wnag

—POST: Doris Hu