How to truing and dressing CNC grinding wheel?

Truing is the process of changing the shape of the grinding wheel as it becomes worn from an original shape, owing to the breaking away of the abrasive and bond. This is done to make the wheel true and concentric with the bore or to change the face contour for form grinding. While The purpose of dressing is to restore the correct cutting action of the wheel. Dressing removes the clogs on the surface of the wheel and the blunt grains of the abrasive, exposing the new sharp abrasive grains of the wheel which can be cut and brought to shape efficiently.

In short, truing creates a smooth surface on the wheel periphery, and with no exposed grit the wheel won’t cut. Dressing sharpens the wheel by removing bond material and fracturing the superabrasive grit to expose fresh edges, so dressing always follows truing. The whole dressing process include truing and sharpening.

Truing is done by using a grinding machine and an abrasive wheel that the bond of the diamond wheel.

Recommended truing parameters:

| Grinding Wheel | Silicon Carbide (green) or Aluminum Oxide (White or Pink) |

| Grit size | 80-120 mesh ,also depend on grinding wheel grit |

| Hardness | E,G,H, J or K |

| Grit of Diamond/CBN wheel | Recommended grit and hardness of truing wheel |

| D/B 301 | 46#(M) |

| D/B 251 | 46#(M) |

| D/B 126-251 | 60#(K/J) |

| D/B 91-126 | 80#(J/H) |

| D/B 64-126 | 120#(H/G) |

| D/B 46-64 | 180-220#(H/G) |

| D/B 25-45 | 240#(H/G) |

| D/B 20-25 | 320#(G/E) |

| D/B 7-20 | 500#(E) |

| D/B 3-5 | 800#(E) |

| D/B 1-3 | 1000#(E) |

Cutting (rotating) speed

| Linear speed of Diamond/CBN wheel | 2-6m/s |

| Linear speed of Diamond/CBN wheel | 8-25m/s |

| Oscillation rate | 200-1000mm/min |

| Feed rate for roughing | 0.02-0.08mm |

| Feed rate for finishing | 0.005-0.02mm |

| * Use coolant whenever possible

* When dressing fine grain grinding wheel, the corresponding speed and feed should also be reduced |

|

In addition, increasing the wheel rotation speed or decreasing the feed speed can increase the surface finish.

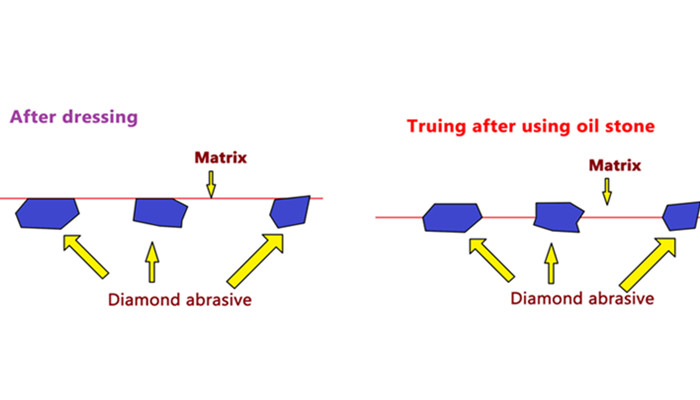

After truing, the grinding wheel has almost no free abrasive particles with cutting ability and needs to be sharpened via dressing to obtain exposed abrasive particles.

Dressing is usually done by using a soft dressing stick with fine grits. It is done by pushing the dressing stick firmly into the diamond wheel, few times, until the wheel sinks into the stick

Attention tips when dressing:

1. Soak the dressingsticks with coolant

2. During the dressing process the diamond wheel should rotate in the same direction and speed as it is normally used.

3. Dressing should be done right after the truing and in any time that the wheel is clogged and generating more load

Recommended dressing stick:

– Aluminum Oxide (White)

– General grit size, 240-320 mesh

– Hardness G or H

| Grit of Diamond/CBN wheel | Recommended grit of dressing sticks |

| ≥D/B 76 | WA 120# |

| D/B 46-64 | WA 240# |

| D/B 25-46 | WA 320# |

| ≤D/B 20 | WA 500# |

General selection guide for dressing wheel/stick

“Truing” primarily means to create a perfectly round and true running grinding wheel

| Truing Data – Truing Wheel | |||

| Hardness | Grain size | Abrasive | Grain Size of diamond |

| J~L | #30~46 | GC,C | #~80 |

| I~K | #45~80 | GC,C | #100~180 |

| I~K | #80~120 | GC,C | #220~360 |

| H~J | #120~220 | GC,C | #400~ |

| Dressing Data – Dressing Stick | |||

| Hardness | Grain size | Abrasive | Grain Size of diamond |

| G~H | #80~220 | GC,WA | #100~180 |

| G~H | #150~600 | GC,WA | #220~400 |

| G~H | #280~1200 | GC,WA | #500~1000 |

| F~G | #600~2000 | GC,WA | #120~2000 |

—-EDITOR: Doris Hu, Julia Zhang

—-POST: Doris Hu