How to choose diamond grinding wheel for sharpening circular saw blade?

Carbide saw blade is usually used for wood products. How to sharpen the carbide saw blade correctly is related to the sharpness and service life of carbide saw blade. Therefore, it is important to choose suitable diamond grinding wheels for sharpening carbide saw blades except for technology.

Tungsten carbide saw blades are designed for cutting wood. however, the cutting effectiveness of a tungsten carbide saw is mostly determined by the geometry of the blade, the sharpness of the teeth, and the chip load per tooth. the process for manufacturing and maintaining the saw’s optimum geometry, sharpness, and load is referred to as circular carbide saw blades grinding.

Diamond grinding wheels for sharpening carbide saw blades consists of three distinct but inter-related processes.

Face grinding Side grinding Top grinding

How to choose Diamond grinding wheels for sharpening carbide saw blades?

Grinding wheels for the tooth face:Depending on the tooth pitch, differently shaped grinding wheels are needed to grind the tooth face. The greater the number of teeth around the circumference, the narrower the space between them and the thinner the grinding wheel has to be. Even the narrowest tooth gaps can be machined with our Tiger grinding wheels. For reasons of stability, conventional tooth gaps are mainly ground using 4A2, 12V2 or 12V9 grinding wheels.

Top grinding is also the peripheral grinding process of circular saw blades. The aim to top grinding is to ensure the circularity of the saw is optimized and defines the wedge and clearance angles, both of which are crucial for the cutting performance of circular saw. Usually using 6A2,6A9 and 12A2 grinding wheels.

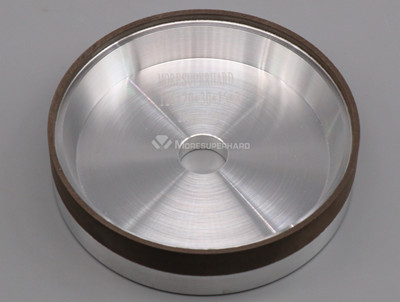

1. Resin bond diamond grinding wheels

The bond strength of this type of diamond grinding wheel is weaker than that of other wheels. The self-sharpening for carbide saw blade is better, no blocking. The grinding force and grinding temperature are low. Wear resistance is poor, and the wear of abrasive tools is high and is not suitable for heavy load grinding.

2. Vitrified bond diamond grinding wheels

The wear resistance and bonding strength of vitrified bond diamond grinding wheel is higher than that of resin bond diamond grinding wheel, and the cutting is sharper and efficiency is higher when grinding. It has better control for heating, blocking, thermal expansion and accuracy. But the surface of saw blade after sharpening is rough and the cost is higher than other wheels.

3. Metal bond diamond grinding wheels

Metal bond diamond grinding wheel has high bonding strength and good wear resistance, low wear ratio when sharpening, long service life, low cost, and withstand big loads. But self-sharpening is low and blocks easily.

Must keep the included angle between the grinding wheel and carbide saw blade unchanged during the re-grinding process, which is also the requirement of a feature of carbide saw blade.After sharpening the carbide saw blade, the angle between the front and rear keep unchanged. The included angle between the working face of the diamond grinding wheel and the front and back teeth of the required grinding face is the grinding angle. The movement distance of the diamond grinding wheel is stock removal.

The higher the grinding speed, the higher the grinding heat, the tooth edge burns easier. The higher the feed speed, the larger the grinding heat and residual stress of the tool, the larger the wear loss of the grinding wheel. To minimize the number of abrasive grains falling off and improve the surface grinding quality, it should reduce the feed speed. The grinding depth is 0.01-0.05mm in rough grinding and the feed speed is 1-2 m/min.

Dish diamond grinding wheels can grinding tooth back face and tooth front face. During grinding the tooth back face, the angle between the grinding wheel working face and the back teeth face is equal to the bevel angle of the back teeth, which should be sharpened staggered every other tooth. When sharpening the back of the flat teeth, the grinding wheel working face should be parallel to the back teeth face.

During grinding the tooth front face, when the front bevel angle is zero, the diamond grinding wheel working face and tooth front face is perpendicular to the horizontal surface. When sharpening the saw blade with a front bevel angle, the saw table or grinding wheel should be inclined at an angle equal to the front bevel angle. In addition, staggered sharpen every other tooth.

—EDITOR: Doris Hu

—POST: Doris H