How to choose the suitable grinding wheel when for fluting carbide tools on CNC tool grinder?

CNC tool grinder is widely used, how to choose the right grinding wheel to get a good grinding effect? The commonly used resin bond grinding wheel and metal bond grinding wheel and hybrid bond grinding wheel are used for cutting tool grooving.

Resin bond grinding wheel has a certain elasticity, can play a role in polishing, the finished tools are better. But the high temperature resistance of the resin is not very high, the temperature exceeds a certain temperature and the shape retention will decline, and the rounded corners are easy to appear.

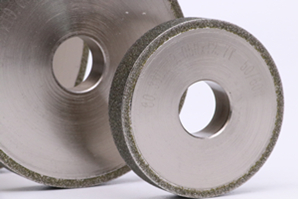

Metal bond grinding wheel has high strength, high temperature resistance, good shape preservation and high grinding efficiency. But the metal hardness is relatively high, not easy to trim.

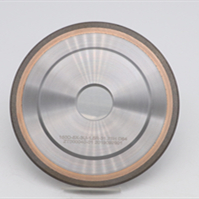

Hybrid bond diamond grinding wheel has the elasticity and good finish of resin bond, and has the wear resistance and good shape retention of metal bond, so it is a good choice for cutting tool powerful grooving.

The single side cutting depth of grooving can be up to 6mm and the feed speed can be up to 90-120mm/min. Due to the small grinding resistance and low grinding temperature, there will be no crack, burn and thermal deformation of the bar when the powerful slotting wheel is processed. At the same time, the powerful slotting grinding wheel has little wear and tear when it is used, and the dressing cycle and service life of the grinding wheel will be greatly improved