How to perform“mirror grinding” ?

what is mirror grinding?

The surface roughness Ra< 0.01µm and the flatness plane is< 3µm/1000mm after the workpiece grinding.

Method of mirror grinding

1. Balance and dressing grinding wheel

1) Balance the grinding wheel. After the grinding wheel is installed with the flange, the first static balance is performed, and then the end face and outer circle are trimmed on the grinding wheel shaft and then the precise static balance is performed.

(2) Dressing the grinding wheel.

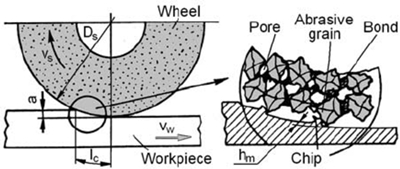

The dressing of the grinding wheel directly affects the smoothness of the grinding surface.

Pay attention to the following matters when dressing the grinding wheel:

1) The general fine grinding allowance is 0.015~0.02mm. When the workpiece is coarsely ground to Ra0.8, the fine grinding allowance is 0.005~0.015mm (the remaining grinding allowance must be determined according to the nature and hardness of the steel. The steel with high hardness and easy to be polished should have less grinding allowance), then the grinding wheel needs to be refined.

2) When fine processing the grinding wheel, first grind off the thickness of 0.1mm, then dressing it twice with 0.02mm depth of cut , then dressing three times with 0.01mm depth of cut, and finally reciprocate twice without the depth of cut.

During fine processing, the lateral feed speed is 20~30mm/min. For mild steel workpieces, it is better to slow the lateral feed when grinding the grinding wheel, and the opposite is true when processing hardened high-speed steel.

3) While dressing the grinding wheel, sufficient grinding fluid must be used to flush away the grinding wheel debris in time to avoid affecting the grinding quality.

4) The diamond tools used in finishing does not need to be very sharp, because the grain size of the grinding wheel is relatively coarse. The diameter of the diamond tip can be within 0.8mm. When dressing with sharper diamond tools, the traverse feed speed must be slowed down.

5) When the newly-dressed grinding wheel is used, the surface roughness is slightly worse, and it will stabilize after a while.

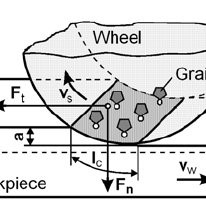

2. Grinding amount

1) The amount of tools on the back of the grinding wheel is about 0.005 mm. Appropriate increase or decrease according to the nature and hardness of the workpiece steel. For example, hardened steel with high hardness can easily cause burns with more cutting feed.

2) The single stroke of the horizontal feed is 0.2~0.4mm. The speed of the lateral feed has a greater influence on the surface roughness, because the grinding wheel for mirror grinding has poor cutting ability. If the lateral feed speed increases, the surface of the grinding wheel will be damaged, so very smooth surface cannot be obtained.

3) The longitudinal feed rate is 12~15 m/min. The longitudinal feed has a relatively small effect on the surface roughness, but if it is too slow, the surface of the workpiece will produce ripples or patterns.

4) No-cut deep polishing. The tool marks often appear due to the poor cutting ability of the grinding wheel during mirror grinding, which reflect the uneven surface of the workpiece, so no-feed smooth grinding is required about two minutes.