Influence of grinding wheel blockage on cutting force and grinding wheel vibration

Cutting Force: The cutting force of a grinding wheel is caused by two functions: chip formation and friction; It is generated by physical contact between the grinding wheel structural parts and the workpiece. Under the specified conditions, in the total cutting force, the cutting force related to friction is much larger than that related to chip formation. Because the two cutting forces are associated with each other during chip formation, they are not easily distinguished. Less friction can provide a freer cutting force and reduce surface heat and blockage of the grinding wheel. The cutting force determines the lifespan, abrasion resistance, energy and other grinding standards.

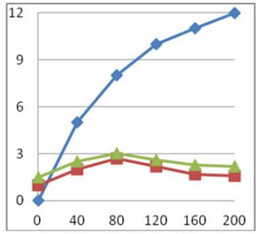

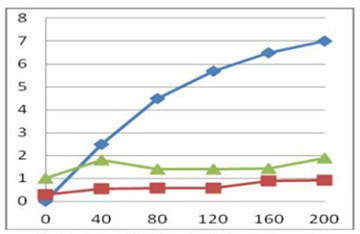

In this study, some experiments were conducted to analyze the influence of grinding wheel blockage on different materials. In the experiment, a single point diamond point was used to dress the grinding wheel. The radial and tangential forces are obtained by fixing the workpiece to the dynamometer. The plugging curve of grinding wheel and the corresponding radial force and tangential force variables are also obtained. The initial rapid blockage of the grinding wheel is due to the contact between the new cutting surface and the workpiece, resulting in holes on the grinding wheel and blockage by chip. As the grinding wheel wears away, the blocked particles slowly fall off, and the blocking rate gradually decreases. In the latter stage, it was found that there was a steady net increase in the amount of clogging, indicating a positive difference between the amount of new clogging chips and the amount of shedding chips. The increase rate of the plugging rate in aluminum processing is higher than that in mild steel and copper processing. FIG. 1 shows the grinding wheel blockage curve during the processing of mild steel by corundum grinding wheel; FIG. 2 shows the grinding wheel blockage curve when corundum grinding wheel processes copper.

The factors that lead to the increase of cutting force also lead to the increase of blockage of grinding wheel. The total cutting force determines the abrasion degree of the grinding wheel to a great extent, and the relationship between the tangential force and the orthogonality gives the measurement method of the cutting ability of the grinding wheel.

Cutting force measurement: In order to carry out qualitative analysis on metal cutting technology, corresponding observation should be made before, during and after cutting operation; One of the most important is the composition of the cutting force, for this purpose, the experiment used a dynamometer tool.

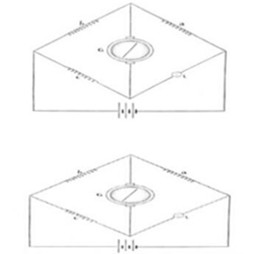

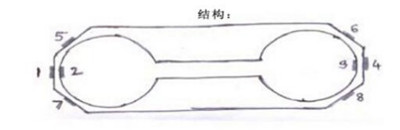

FIG. shows the distribution of strain gauges in Wheatstone bridge. The radial and tangential forces between the grinding wheel and the workpiece are measured with a dynamometer during surface grinding. Two octagon half-rings were fabricated from aluminum, and four strain gauges were fixed on each half-ring and connected to form two complete Wheatstone Bridges. Used to measure the vertical and horizontal components of the cutting force respectively.

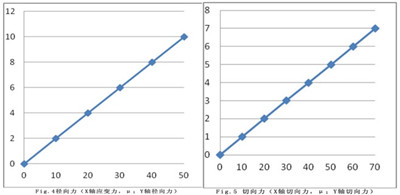

Calibration of dynamometer: The dynamometer is calibrated by radial and tangential coordinates. Vertical milling machine is used to complete the calibration of dynamometer in the experiment.

Radial force: tighten the bottom plate with a vise and fix it on the workbench. The stress ring is placed in the center of the box fixture and the vertical head is gradually lowered to load the dynamometer. Tensile readings of different stress rings can be read out. It is found that the calibration curve of stress and radial force is linear.

The dynamic calibration to evaluate the natural frequency of the dynamometer is accomplished by the vibrator. Load a certain load on the dynamometer and record the strain force; A load of the same size is kept for several minutes, and the value of the strain force is recorded at intervals. It was found that there was no change in the strain force.

Vibration: The vibration generated during the cutting process will usually cause the formation of ripples on the surface of the grinding wheel and around the workpiece. The main causes of vibration are cutting time, grinding wheel diameter and hardness.

Cutting vibration is divided into three types:

Machine tool forced vibration caused by excitation force; The source of forced vibration is mainly related to the unbalance of grinding wheel.

Passive vibration transmitted from other machine tools.

Self-excited vibration produced by internal force during cutting without any periodic external force.

The vibration of the grinding wheel has a certain influence on the cutting process, including the regular violent vibration of the grinding wheel and the workpiece. As the cutting time increases, the distance amplitude between the grinding wheel and the workpiece increases. When the amplitude reaches a certain level, traces of vibration remain on the workpiece. The vibration frequency caused by small grinding wheel is higher than that caused by large diameter grinding wheel.

When the grinding wheel is blocked, the magnitude of cutting force and vibration increases, and then decreases with the grinding wheel’s abrasion and blockage to some exte