RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

Diamond tools for stone industry

2021-08-25Application: processing ceramic tile, granite, marble, limestone, quartz stone, sandstone, basalt, bluestone, shale and other natural stone, or concrete, refractory materials, ceramics, asphalt, cement pipe, microcrystalline stone, vitrified brick and other artificial imitation stone materials.

Learn More

-

Aluminum Alloy Hole Machining Tool

2021-08-25PCD reamer has unparalleled processing advantages in cutting force and surface roughness. The tool has a long service life, which effectively reduces the number of tool changes and tool adjustment time, and can realize multiple grinding, which significantly improves the accuracy and smoothness of the machined surface.

Learn More

-

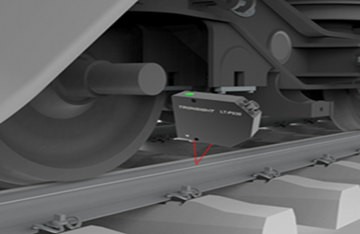

Resin CBN grinding wheel for grinding the train track

2021-08-25CBN grinding wheel is feasible in the field of processing the fat edge of railway track, which can improve the processing efficiency by 15 ~ 20 times

Learn More

-

The importance of binder

2021-08-25Abrasive is generally composed of abrasive, bond and porosity, these three parts are often called the three elements of the consolidated abrasive. Abrasives have a cutting effect in abrasives. A bond is a material that cements loose abrasives into abrasives.

Learn More

-

The process of backside grinding of silicon wafer

2021-08-25Learn More

-

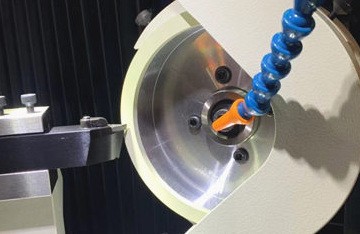

Grinding quality of PCD tool with diamond wheel

2021-08-25PCD tool must ensure good cutting edge before machining workpiece. Diamond grinding wheel is the most widely used method. The higher the quality of the cutting edge, the finer the tool mark left at the junction of the geometric reflection region of the workpiece surface, and the higher the surface finish of the workpiece. Because cutting edge collapse or expansion easily cause tool wear or damage, reduce tool life. Edge collapse is a key index of edge quality of diamond tools.

Learn More

-

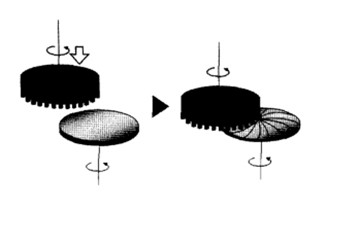

Technology of dressing grinding wheel with diamond roller

2021-08-25The grain size of diamond grinding wheel should be one point coarser than that of the dressing grinding wheel, and the size of diamond particles should be close to the same, and the shape of diamond particles is approximately spherical. The commonly used particle size is 36# ~100#.

Learn More

-

2021 Formnext+PM South China

2021-08-25EXPO will cover a series of advanced materials, technologies, equipment and products such as materials, powder metallurgy, additive manufacturing and post-processing, bringing new business opportunities to the manufacturing industry in China and even Asia.

Learn More

-

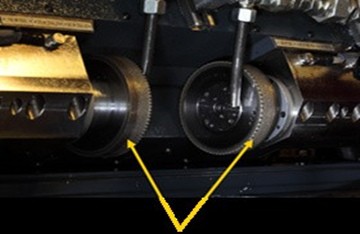

Peripheral Diamond Grinding Wheel Test

2021-08-25Peripheral Diamond Grinding wheels are used for indexable inserts grinding. Peripheral Diamond Grinding wheels for indexable inserts, must be of a high level of geometrical accuracy, with ability of significant material removal.

Learn More

-

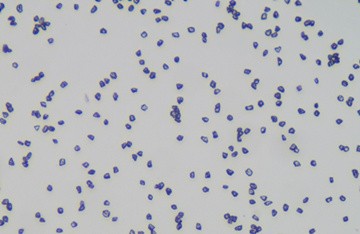

Diamond Powder Test

2021-08-25Diamond powder is mainly used for grinding and polishing, the control of particle size is particularly important. As long as there are oversized coarse particles will cause workpiece scratches so that preceding operation come to naught. So the quality inspection of powder is an important link to ensure the quality of powder products.

Learn More