RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

Resin CBN grinding wheel for tool steel processing

2021-08-25Tool steel refers to a variety of carbon steel and alloy steel that are particularly well-suited to be made into tools. Their suitability comes from their distinctive hardness, resistance to abrasion and deformation, and their ability to hold a cutting edge at elevated temperatures.

Learn More

-

Grinding parameters of plasma sprayed coating

2021-08-25The circumferential velocity of grinding wheel and parts can directly affect the grinding efficiency.

The grinding wheel linear velocity is generally between 30-40 m/s when grinding the surface of the outer circle coating.

Learn More

-

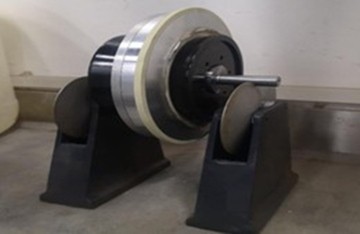

What Do You Know About Dynamic Balance of Grinding Wheel?

2021-08-25Learn More

-

The relationship between grinding wheel wear and feeding speed

2021-08-25Usually, as customer said “anything” is not changed, same grinding wheel, same work piece, same grinding machine, same stuff and same grinding condition. We think they change a very small thing “feeding speed”. Because they want to improve the grinding efficiency, increase the feeding speed is an easy way.

Learn More

-

SNEC PV POWER EXPO 2021

2021-08-25The exhibition scale of SNEC has evolved from 15,000sqm in 2007 to over 150,000sqm in 2020 when it attracted over 1400 exhibiting companies from 95 countries and regions all over the world and the overseas exhibitor ratio is over 30%. SNEC has become the biggest international PV tradeshow with incomparable influence in China, in Asia and even in the world.

Learn More

-

Why use vitrified bond for grinding wheels?

2021-08-25Grinding wheels are often referred to as “industrial teeth”. It generally refers to a solid round object (mostly round with a through hole in the center) formed by bonding coarse abrasive compounds together, which can be used on the outer edge. Numerous hard, sharp, and temperature-resistant small abrasive grains continuously cut and remove the surface of various materials, so they have a pivotal position in industrial production.

Learn More

-

How to grind camshafts of different sizes?

2021-08-25However, There will be a phenomenon of sticking on the surface of the grinding wheel when the grinding wheel is grinding a 22/25mm camshaft, resulting in a decrease in efficiency and an increase in the frequency of dressing.

Learn More

-

Synthetic diamond dressing tool for grinding wheel

2021-08-25Synthetic diamond tools are a more stable quality product because the structure can be controlled more precisely through the manufacturing process and the quality can be predicted in advance.

Learn More

-

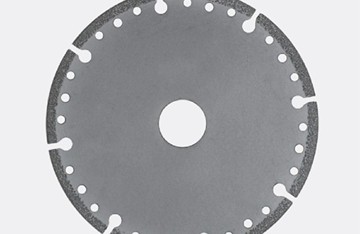

Analysis on the reason of edge broken of diamond saw blade

2021-08-25The strength of diamond is an important index to ensure the cutting performance. High strength will make the crystal is not easy to break, the abrasive particles are polished in use, sharpness decreased, resulting in deterioration of tool performance. When the strength of diamond is not enough, it is easy to be broken after impact and difficult to undertake the heavy cutting task. Therefore, the strength should be between 130 and 140N.

Learn More

-

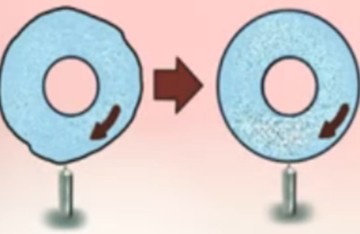

Why should the grinding wheel be dynamically balanced?

2021-08-25The grinding wheel is a necessary tool for the grinding machine. To make the grinding wheel grind to an accurate size and smooth surface, it is necessary to prevent vibration during the grinding process.

Learn More