RELATED BLOG

-

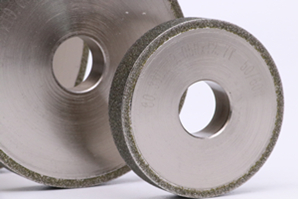

How to choose edge grinding wheel for chamfering wafer

2025-05-10 -

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07

-

How to solve the grinding vibration veins ?

2021-08-24The production of grinding vibration not only affects the machining accuracy, but also causes the workpiece surface roughness can not meet the requirements, so that many problems occur in the working state of the workpiece.

Learn More

-

Selection of grinding parameters of solid carbide tools with diamond grinding wheels

2021-08-23Cemented carbide is tungsten carbide, titanium carbide and other metal carbide as hard phase, with cobalt and other metal as adhesive, made by powder metallurgy method, has a high hardness (up to HRA89-93, Microhardness of 1300-1800N/mm2), low thermal conductivity (16.75-79.55W/m·K), low bending strength (3.0-4.5gpa) and large elastic wear (540-650gpa).

Learn More

-

Hybrid fluting test

2021-08-20Test tool specifications: integral HM twist drill D10.1*61*103*SD10.

Learn More

-

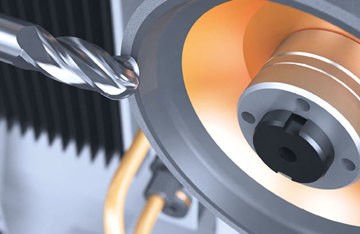

How to choose the suitable grinding wheel when for fluting carbide tools on CNC tool grinder?

2021-08-20CNC tool grinder is widely used, how to choose the right grinding wheel to get a good grinding effect? The commonly used resin bond grinding wheel and metal bond grinding wheel and hybrid bond grinding wheel are used for cutting tool grooving.

Learn More

-

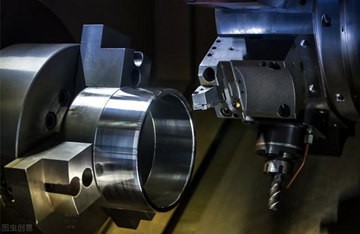

Matters and problems of small aperture internal processing

2021-08-20Because it is often restricted by the diameter of the inner hole of the workpiece, the diameter of the inner circle processing is usually low, the speed is often affected by the speed of the inner spindle of the equipment, and the circumferential speed of the ceramic diamond grinding wheel is often lower than 30-35 m/s. Therefore, vitrified diamond grinding wheels are usually more efficient in machining roughness and cylindrical grinding.

Learn More

-

Moresuperhard will participate in CIOE 2021

2021-08-16CIOE 2021 (The 23rd China International Optoelectronic Exposition), as the world’s leading optoelectronic exhibition, will be held at Shenzhen World Exhibition & Convention Center on September 16-18, 2021. The exhibition focuses on precision optics,chip materials,infrared materials and components and other fields.

Learn More

-

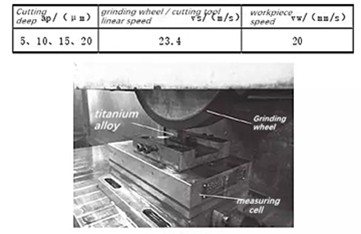

Comparison between CBN and SiC Grinding Wheel for Titanium Alloy

2021-08-04When use silicon carbide grinding wheel or other mixed-abrasive grinding wheels based on green silicon carbide for titanium alloy, the grinding wheel adheres to titanium alloy seriously, which leads to large grinding force and poor processing quality.

Learn More

-

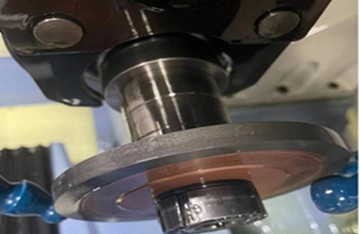

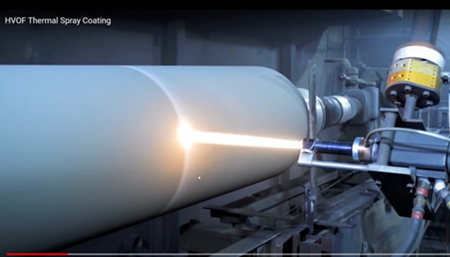

Thermal spraying (tungsten carbide)

2021-08-03Thermal spraying does not mean that how thick can be sprayed, the thicker the thickness, the more difficult the spraying, because it is to be sprayed on the spraying surface again, the sprayed particles are not easy to adhere to it, resulting in loss of waste, so the cost will increase exponentially.The spray thickness is generally 40 wires.

Learn More

-

How to choose internal grinding Wheel?

2021-08-03Diameter of the grinding wheel is too large, the contact arc between the grinding wheel and the workpiece will increase, which will increase the grinding heat and make cooling and row cutting difficult. If the diameter of the grinding wheel is too small, it is difficult to achieve the ideal grinding speed (30m/s~50m/s), which increases the grinding thickness, increases the conformity of the grinding grains, and is easy to blunt, which increases the surface roughness of the inner hole and reduces the production efficiency when grinding the hole of workpiece.

Learn More

-

Dicing Blade selection for wafer cutting

2021-04-13At present, most of the wafer cutting is using high precision scribing machine, which is mainly mechanical processing.

Under the action of mechanical stress, the wafer is prone to quality abnormalities after cutting. Common quality abnormalities include: product surface, back Chipping, PAD oxidation, delamination, missing Angle and other abnormalities.

Learn More