RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

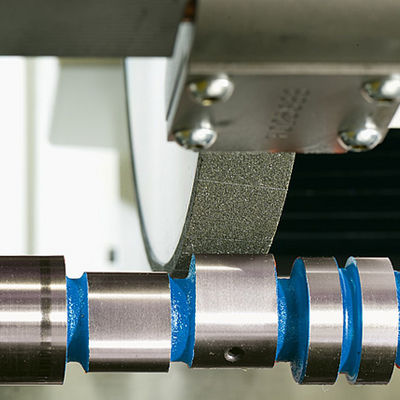

Vitrified bond CBN wheel for grinding camshaft of Motorcycle with low speed

2021-03-19Vitified CBN grinding wheel is mainly used in automobile, motorcycle, diesel, gasoline and other camshafts and crankshafts.Materials include cast iron, carbon steel, alloy steel, bearing steel, etc.It is suitable for Japanese Toyota, German Junker and Schott grinder.

Learn More

-

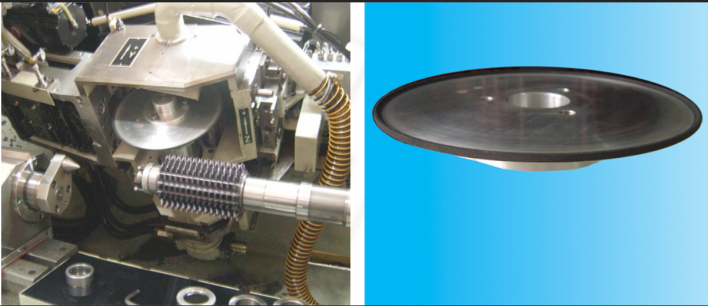

The case of Dressing Hob Cutter

2021-03-18Learn More

-

Spatial Positioning of Diamond Composite Plates

2021-03-17The spatial positioning of the composite is the spatial position where the composite is placed on the drill bit. The spatial positioning of the composite chip is the key point of the design of the composite chip bit, which has a great influence on the drilling performance of the bit.

Learn More

-

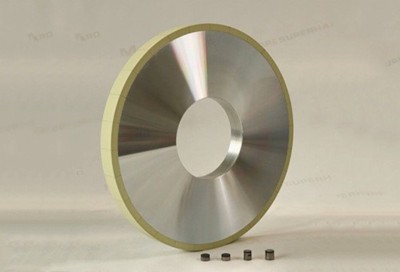

The advantages of vitrified bond diamond wheel for grinding PDC

2021-03-16Vitrified diamond grinding wheels are mainly used in the grinding and processing of PCD tools, CBN tools, carbide, cermets, ferrites, cast iron, gemstones, traditional ceramics and new engineering ceramic materials, and can also be used for chromium-quenched steel bearing rollers, Precision grinding of crankshafts of automobiles and tractors, gear necks of hydraulic pumps, etc.

Learn More

-

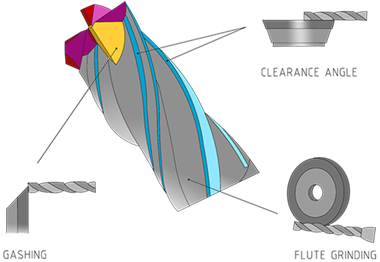

How to grind a Mill Cutter?

2021-03-15Before grinding, should check the grinding wheel. If the grinding wheel is beating, the cylindrical surface is irregular, and the fillet corner is too large, it needs to be dressed. Generally can use grinding wheel dresser(diamond dresser, dentate dresser) to dress the cylindrical surface of grinding wheel; also can use used grinding wheel with relatively large hardness for dressing. If the grinding wheel profile is not smooth, you can replace the grinding wheel.

Learn More

-

How does the Porous Ceramic Vacuum Work?

2021-03-13Ceramic vacuum chuck is a kind of uniform solid or vacuum body made of nano powder. A large number of connected or closed ceramic materials are produced in the material by sintering at high temperatures.

Learn More

-

Safety Manual when use cutting tools

2021-03-11Cutting tools have sharp cutting edges. Handling them with bare hands may cause injuries

Learn More

-

Advantages and disadvantages of indexable tools

2021-03-10One of the most significant benefits of using indexable tools is that cutting edges can be updated don’t need remove the tool from the production site.

Learn More

-

The function of honing cylinder holes

2021-03-09Coarse honing, it is also the first step of honing the cylinder hole. It is mainly used to remove the allowance, eliminate the tool mark in fine boring process, form cylindrical hole with correct geometry and basic surface roughness suitable for subsequent honing process.

Learn More

-

How to do mirror finish grinding by a grinder

2021-03-08Mirror grinding is a grinding that the surface roughness of the workpiece is Ra< 0.01μm, and the light is like a mirror after grinding, so it can be clearly photographed. The flatness of the grinding surface is not greater than 3μm /1000mm. The surface machining of high precision and high added value parts requires mirror grinding.

Learn More