RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

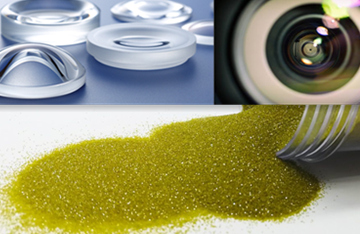

Diamond polishing powder for optical lenses polishing

2024-04-15There are three mainstream polishing methods for optical lenses: mechanical polishing, chemical polishing and chemical mechanical polishing. All three require grinding polishing fluid (powder), which can be divided into diamond polishing powder and diamond compound (the industry also calls polishing fluid abrasive fluid or grinding fluid abrasive fluid). Generally, diamond compound is used for rough grinding, and diamond polishing powder is used for precision grinding. diamond Polishing powder is usually used in the next step of the grinding fluid.

Learn More

-

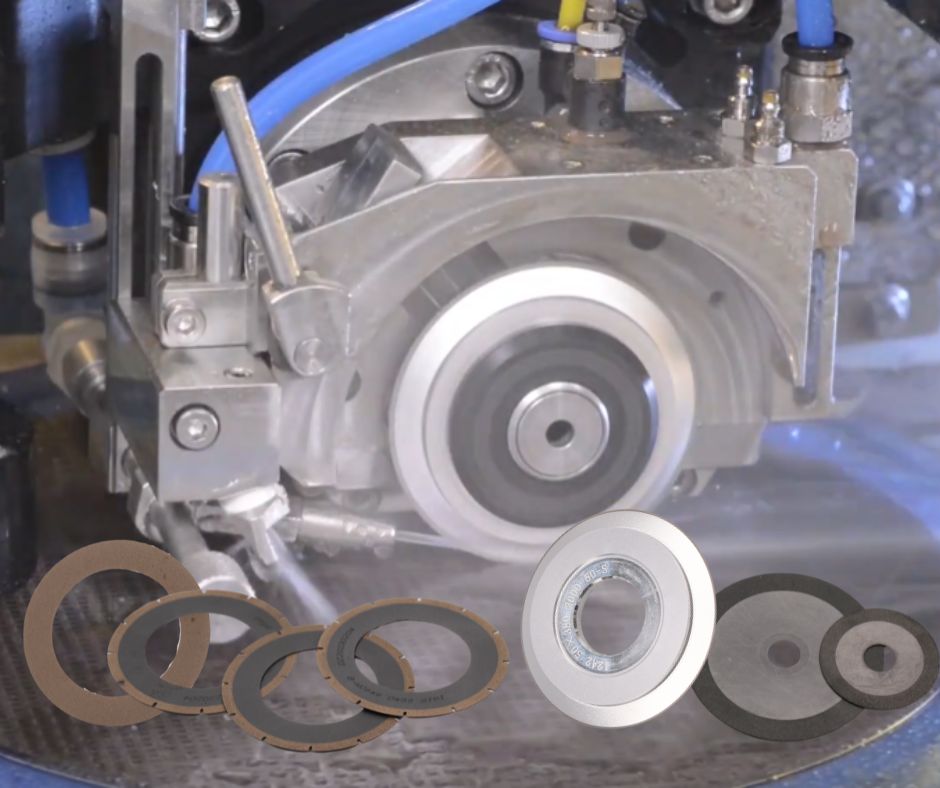

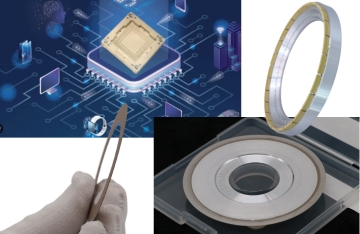

How to select diamond dicing blade for precision dicing ?

2024-04-09Resin bonded diamond dicing blades can be used to cut quartz, glass, lithium niobate, crystals and other brittle and hard materials, IC packages (QFN, DFN), etc.

Metal bond diamond dicing blades can be used to process optical devices, ceramics, ferrite, quartz, IC packaging (BGA), optical communications (Faraday), etc.

Learn More

-

What diamond tools are used to process glass lense?

2024-04-06Moresuperhard can provide grinding wheels(milling grinding wheel and centering wheel) and polishing tools(diamond pellets and polishing pad) for lense processing.

Learn More

-

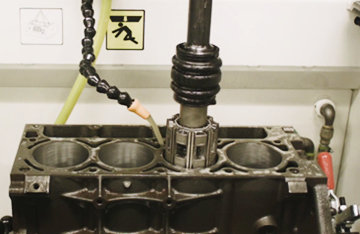

Honing process and its application in automobile parts manufacturing

2024-03-07Honing Process is a special form of grinding and an efficient processing method in finishing. This process can not only remove large machining allowances, but is also an effective processing method to improve the dimensional accuracy, geometric shape accuracy and surface roughness of parts. It is widely used in the manufacturing of automotive parts.

Learn More

-

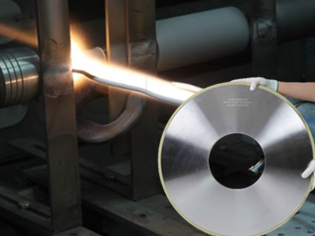

How to grind plasma spray coating?

2024-01-09Grinding of the outer circle and inner hole: The circumferential surface of the grinding wheel is mainly used as the grinding working surface, which is tangent to the machined surface of the part, and the sprayed surface of the outer circle and inner hole is ground.

When the hardness of plasma spraying is relatively high and the processing volume is relatively small, the coating treatment is more suitable for grinding. Because plasma spraying has a special structure, it makes the coating material more difficult to grind. The selection of coating grinding methods and process specifications mainly depends on the structure and hardness of the coating. Reasonable selection of grinding methods and process specifications can not only improve the surface finish and grinding efficiency of the coating, but also reduce the stress at the interface between the coating and the substrate. According to the form of the grinding wheel working surface, there are basically two methods for plasma spraying.

Learn More

-

Grinding problems for the glass industry

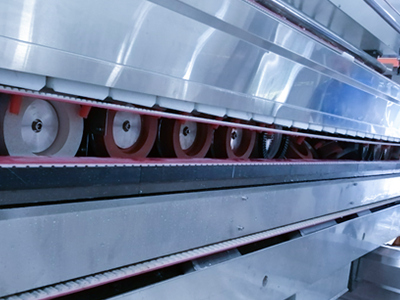

2023-12-01The edge grinding process can effectively improve the brittleness of the glass, making the glass more beautiful and safer. Generally speaking, it is enough to use a coarse grinding wheel to grind off the corners of the glass. However, the requirements for craft decorations are higher and require rough grinding and fine grinding to make the original glass of different shapes and sizes gradually close to the workpiece required by the customer. size and surface roughness.

Learn More

-

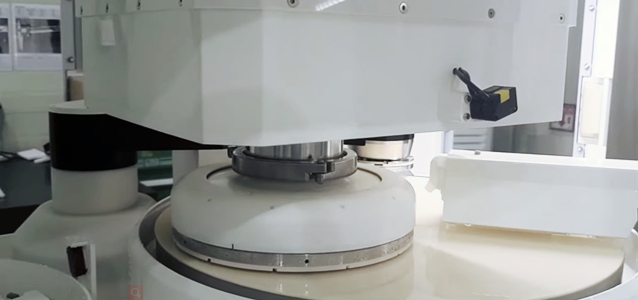

CMP Conditioner for dressing polishing pad in semiconductor industry

2023-11-26CMP Pad Conditioner uses advanced diamond planting technology to fix diamond abrasive grains on the substrate in an orderly manner according to the designed pattern. It uses precision electroplating to match diamonds of different sizes, shapes, and pattern designs to provide different A series of polishing pad removal rate products can be widely used in various scenarios that require planarization.

Learn More

-

The key materials used for semiconductor advanced packaging and testing

2023-11-10Power semiconductor packaging paste (power semiconductor chip packaging sintered silver, ceramic copper clad plate brazing paste, etc.)

This study is also a field of deep digging and extension, need to slowly digest, packaging is an important step during the semiconductor process, also involves the packaging grinding products used, Moresuperhard have many customers in the the current packaging grinding, and cutting but also need to expand.

Learn More

-

How to solve the white edge of glass grinding?

2023-11-01The edge grinding process can effectively improve the brittleness of the glass, making the glass more beautiful and safer. Generally speaking, it is enough to use a coarse grinding wheel to grind off the corners of the glass. However, the requirements for craft decorations are higher and require rough grinding and fine grinding to make the original glass of different shapes and sizes gradually close to the workpiece required by the customer. Size and surface roughness.

Learn More

-

Comparison of honing and internal grinding

2023-10-26Different grinding methods

Honing is the workpiece does not move, honing head for rotation and up and down reciprocating movement. Internal grinding requires that the grinding pin rotates and reciprocates after the workpiece is clamped.

Grinding different holes

Honing is mainly suitable for some longer and deeper through holes and blind holes. Internal grinding generally works short holes.

Learn More