RELATED BLOG

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05

-

Safety Manual when use cutting tools

2021-03-11Cutting tools have sharp cutting edges. Handling them with bare hands may cause injuries

Learn More

-

Advantages and disadvantages of indexable tools

2021-03-10One of the most significant benefits of using indexable tools is that cutting edges can be updated don’t need remove the tool from the production site.

Learn More

-

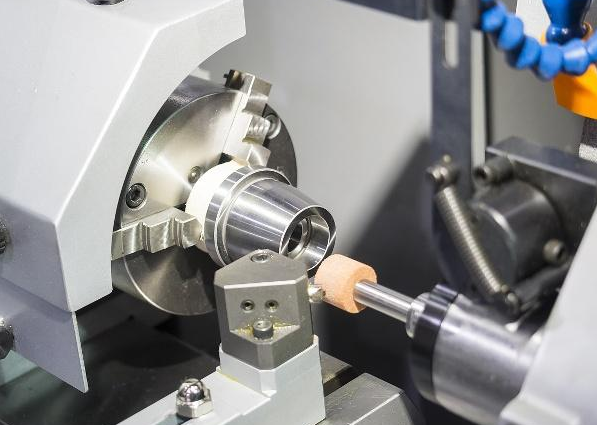

The function of honing cylinder holes

2021-03-09Coarse honing, it is also the first step of honing the cylinder hole. It is mainly used to remove the allowance, eliminate the tool mark in fine boring process, form cylindrical hole with correct geometry and basic surface roughness suitable for subsequent honing process.

Learn More

-

How to do mirror finish grinding by a grinder

2021-03-08Mirror grinding is a grinding that the surface roughness of the workpiece is Ra< 0.01μm, and the light is like a mirror after grinding, so it can be clearly photographed. The flatness of the grinding surface is not greater than 3μm /1000mm. The surface machining of high precision and high added value parts requires mirror grinding.

Learn More

-

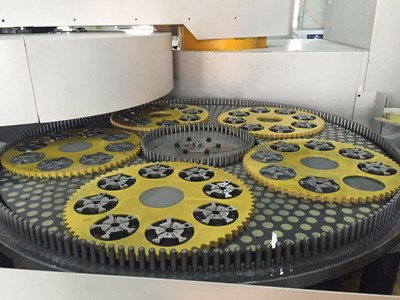

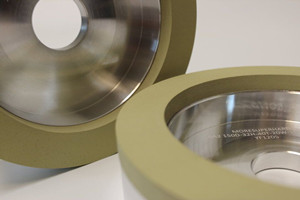

Machining PCD/PCBN tools with vitrified bonded diamond grinding wheel

2021-03-08Polycrystalline diamond (PCD) material, polycrystalline cubic boron nitride (PCBN) material, diamond or CBN micro powder under high temperature and high pressure synthesis on the cemented carbide matrix, it overcomes the anisotropy characteristics of diamond and cubic boron nitride single crystal, has high hardness and high wear resistance, it is an ideal tool material, and widely used in automotive, aviation, aerospace, building materials and other fields of processing.

Learn More

-

How to solve DDG Grinding Wheel problems?

2021-03-04During the grinding process, the CBN grinding wheel burns workpiece

- The hardness of the CBN wheel is on the high side, should replace the proper grinding wheel

- Coolant nozzle direction is wrong or the flow is not sufficient: Adjust the direction of the nozzle of the coolant and increase the flow

- The dressing of CBN wheel is not sufficient: Replace CBN grinding wheel dresser and carry out new grinding wheel dressing

- The feed rate of workpiece is too high: Reduce the amount of feed appropriately

Learn More

-

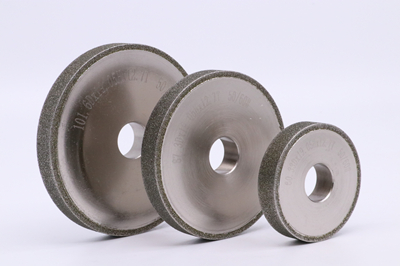

Analysis of the advantages of electroplating bond grinding wheel

2021-03-02Electroplated grinding wheels usually use electroplated nickel or nickel-cobalt alloy as binder. Itself has high hardness and high strength, coupled with compact structure and strong binding force, so that the overall hardness of the working layer is significantly higher than that of bronze and resin binder.

Learn More

-

14 Important Parts of Centerless Grinder

2021-03-01The base is a solid heavy cast iron structure that supports other parts of the machine. It contaThe base is a solid heavy cast iron structure that supports other parts of the machine. It contains the hydraulic oil tank and the grinding wheel head assembly.

Tip: A machine with a solid base will increase the rigidity of the machine and reduce vibration.

2. Swivel Plains the hydraulic oil tank and the grinding wheel head assembly.

Tip: A machine with a solid base will increase the rigidity of the machine and reduce vibration.The base is a solid heavy cast iron structure that supports other parts of the machine. It contains the hydraulic oil tank and the grinding wheel head assembly.

Tip: A machine with a solid base will increase the rigidity of the machine and reduce vibration.

2. Swivel Pla

Learn More

-

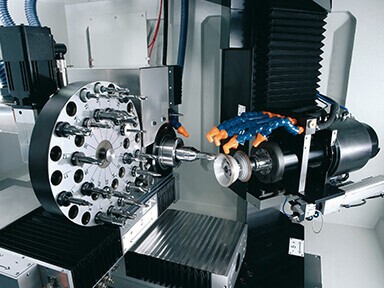

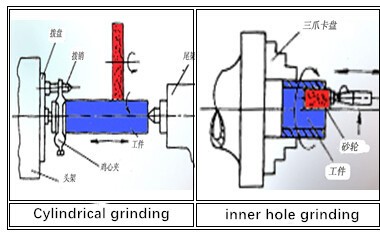

Grinding technology of diamond wheel

2021-02-07Compared with outer circular grinding, inner circular grinding mainly has the following characteristics.

Learn More

-

The Relationship between RPM and Surface Finish of Wheel

2021-02-03There is a direct relationship between the rpm of a wheel , and the surface finish achieved from the tool. The principle is centered over the size of the chip generated from the cutting tool.

Learn More