RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

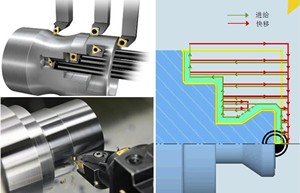

The difference between transverse turning and longitudinal turning

2020-12-10- Not all profiles can be transversely turned with a limited number of tools, and more tools may need to be replaced during machining

Learn More

-

Get our 2021 Calendar in your next order !

2020-12-09Electroplated diamond and CBN tools provide very sharp grinding ability, widely used in stone cutting, gems grinding, tungsten carbide and HSS tools sharpening. With the excellent machine work, Also, “More Super Hard” supplies very high-precision electroplated tools which are mainly used in gear, automobile industry and form grinding solution.

Learn More

-

What are the advantages of grinding compared with cutting?

2020-12-08Grinding can achieve surface finish under Ra=6um, dimensional tolerance under 5um, and can grind parts to a true roundness under 0.03um.

Learn More

-

Improve the processing stability of internal grinding

2020-12-07Main problem: the quality of internal grinding results is not stable.

Reason: Because the abrasive particle size of fine grit grinding wheel is small and the binder is not easy to adhere to in cause of the quality is different.

Learn More

-

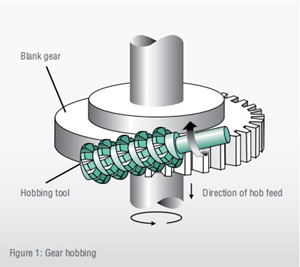

Gear Manufacturing

2020-12-03Hardening/Heat-Treating is a group of processes used to

alter the physical, and sometimes chemical, properties of a material.

Treatment involves the use of heating or chilling, normally to extreme

temperatures, to achieve to desired result such as hardening or

softening of a material. Heat-treatment techniques include annealing,

case hardening, precipitation strengthening (age hardening),

tempering and quenching.

Learn More

-

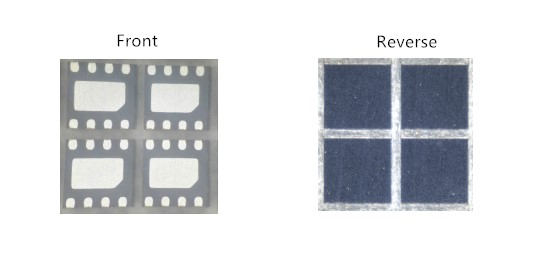

Diamond Dicing Blade for DFN Semiconductor packaging

2020-12-02The Diamond dicing blade is mounted on the soft blade flange of the cutting equipment’s spindle. Under high-speed rotation of the spindle at RPM 20,000 to 30,000, the workpiece to be cut are broken by fracturing way and the chip pocket to remove the chips in time to ensure the processing quality.

Learn More

-

Moresuperhard set off again — Attend International Forum & Exhibition on Precision Manufacturing at Kunshan

2020-12-02The forum will have the invited oral presentations from the engineering practitioners, leading researchers, industrialists and academics, and in parallel the industrial exhibitions from leading companies in the field. Both of them will try to show off the best practices, innovation ideas, products and services. Furthermore, there will be industrial round table discussions, demos and meetings with Venture Capitals in precision engineering and the companies’ tour.

Learn More

-

Semiconductor Packaging –The Cutting of DFN Finished Products

2020-12-01With the continuous progress of electronic information, the semiconductor industry is also changing with each passing day. In order to meet the market demand, the manufacturing process of all kinds of electronic control components is also developing towards the direction of small volume, excellent performance and low energy consumption. Such as IC packaging DFN, QFN, BGA and other process types.

Learn More

-

Why is it necessary to grind after hard turning?

2020-11-30The purpose of grinding as the finishing step is to obtain the surface quality which cannot be achieved by hard machining. Shaft products require high surface quality of bearing mounting position or sealing position. For example, some surfaces require a non-helical surface, which is not possible with hard cars. Some parts are severely discontinuous, and turning can be a quick way to remove the margin. The precision grinding process is then used in the same clamping process in order to precisely grind to the required size and surface quality. Because the margin of grinding after hard lathe machining is very small, the grinding wheel wears lightly, which can reduce the dressing times and improve the processing efficienc

Learn More

-

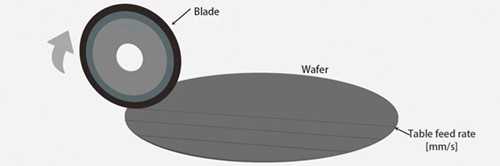

Diamond grinding Pad

2020-11-28Pre grinding, the cutting force will be very high, so the shorter grinding time is better.

Learn More