RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

DMP Greater Bay Area Industrial Expo

2020-11-26The “DMP Greater Bay Area Industrial Expo” will be held in Shenzhen International Convention and Exhibition Center (New Pavilion) from November 24 to 27, 2020, with an estimated scale of 320,000 square meters.

Learn More

-

Diamond Dressing Tools

2020-11-26Single-point cone tool – A single-stone diamond is embedded in one shank. This tool is good for complicated forms and radius dressing. As the diamond wears, a flat will develop, resulting in a dull grinding wheel. As a result, frequent rotation of the diamond tool is required.

Learn More

-

Analysis and solutions of the coating falling off of electroplated diamond tools

2020-11-25With the development of economy and the progress of science and technology, different industries have basically the same requirements for electroplated diamond tools, that is, high efficiency, long life, and high grinding precision. To ensure these characteristics, the coated metal must not only have higher hardness and wear resistance, but also must be evenly distributed in all parts of the substrate to prevent the coating from falling off and shorten the tool life. In some special industries, such as powerful grinding in the magnetic material industry, the feed rate is controlled at about 0.3mm.

Learn More

-

New research of ultra-sonic cleaning for diamond grinding wheels

2020-11-24Recently, we have a customer met a problem in his grinding work. He is using our resin bond diamond grinding wheel for this carbide workpiece grinding. The wheel works very good in the beginning, but later, he finds the wheel is blocked by the chippings. Grinding wheel losses grinding ability, becomes dull and grinding efficiency reduced very much. Under this circumstance, he asks me for help. This is a common issue during grinding work, not a big problem, and very easy to control.

Learn More

-

Why choose CBN Grinding Wheel For Gear Hob Grinding ?

2020-11-23The inner hole of high speed steel hob will be deformed after carburizing heat treatment. The unilateral deformation will range from 0.1 mm to 0.25 mm, and the surface hardness can reach above HRC60 degrees.

Learn More

-

Single stroke honing process VS multi-stroke honing process

2020-11-20Multi-stroke honing process and single-stroke honing process. Multi-stroke honing process means that the honing head can make several strokes during the processing of the workpiece. There are mainly horizontal and vertical honing machines to choose from.

Learn More

-

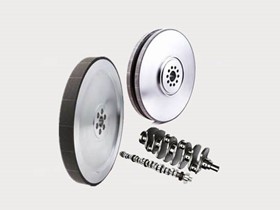

Comparative Study on the application of Vitrified CBN Wheel and Corundum Wheel in engine manufacturing

2020-11-19Vitrified CBN grinding wheel has the advantages of good thermal stability, good wear resistance, not easy and elements of iron group produces chemical reaction, suitable for processing hard and toughness of steel, the auto industry is the main vitrified CBN grinding wheel’s application domain, especially as the key parts of engine camshaft and crankshaft processing aspect, the camshaft and crankshaft machining quality directly affects the dynamic performance of the engine.

Learn More

-

What is the difference between high efficiency centerless cylindrical grinding and ordinary cylindrical grinding?

2020-11-18Ordinary cylindrical grinding uses the center holes at both ends of the workpiece to support the workpiece between the headstock and tailstock center of the grinder. During grinding, the workpiece rotates under the drive of the main shaft, and the grinding wheel makes lateral feed.

Learn More

-

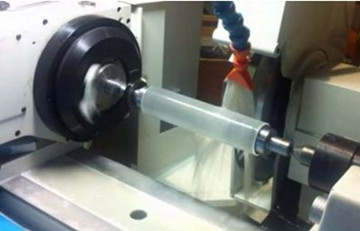

What Is Peel Grinding?

2020-11-17Two enabling technologies — superabrasive wheels and high precision servo control — come together to provide a contour grinding process that resembles an OD turning operation. For many medium volume OD grinding applications, this method may be a means to consolidate several manufacturing steps into a single setup.

Learn More

-

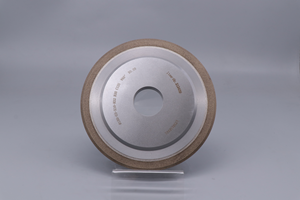

Manufacturing process of high precision diamond roller and fault cause during dressing

2020-11-13At present, sintering method is the main method in China. Compared with electroplating method, it has a longer life and more stable performance. On the contrary, electroplating method is more widely used than sintering method in foreign countries. The following figure shows the manufacturing methods and characteristics of sintered diamond rollers and electroplated diamond rollers.

Learn More