RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

Why do aircraft use carbon fiber composite materials?

2020-10-13In recent years, everyone must be familiar with carbon fiber composite materials. Carbon fiber composite material is ubiquitous in all kinds of science fiction, racing movies. Such as the 350Z body in the Tokyo Drift “The Fast and the Furious Ⅲ”, the wings of the falcon in “Avengers”, the torso of the Baymax in “Big Hero 6” are all made of carbon fiber materials.

Learn More

-

Grinding Out Bottleneck Diamond & CBN lapping plate

2020-10-09The dressing wheels are used for dressing diamond and CBN wheels. According to the different particle size, accuracy of the diamond and CBN grinding disc to choose the dressing wheel, making dressing easier and more time saving.

Learn More

-

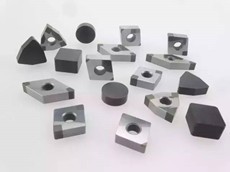

Super Hard Abrasive–Diamond

2020-10-08In addition to the standard, according to the American standard, the grit size ranges from 60 to 325, and the fine powder grade ranges from 400 to 14000. Please refer to the following table.

Learn More

-

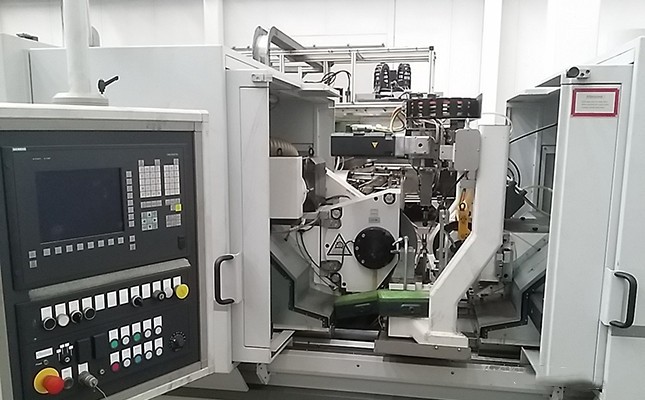

Application of CBN grinding wheel in grinding process

2020-10-07The camshaft on the automobile engine has multiple cams, and the rough grinding and fine grinding of the cam after quenching are the key processes that affect the quality of the cam. In general, imitative grinding is used, and the speed of the workpiece is limited, and the workpiece is prone to grinding burn cracks.

Learn More

-

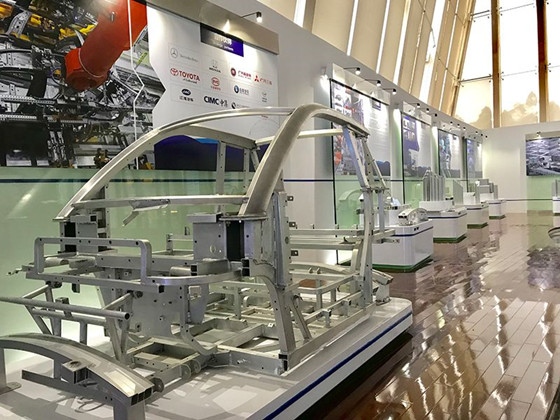

Application research of aluminum alloy in automotive lightweight field

2020-10-06It is possible to make auto parts with aluminum alloy instead of steel because of its advantages such as light weight, high specific strength, corrosion resistance, good formability and recycling.Learn More

-

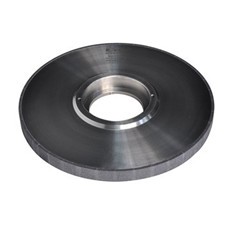

Rotary diamond dresser for dressing bearing LM guide grinding wheel

2020-09-24Grinding of guide parts often requires strict control of its profile and roughness. Whether in car pulleys or in complex bearings such as double guide ball bearings, the clearance accuracy and matching rate of the final product often directly affect the customer’s Production and user experience. However, it is clear in the industry that after the grinding wheel is manufactured, it is necessary to perform dressing to grind the workpiece to ensure the accuracy of the workpiece.

Learn More

-

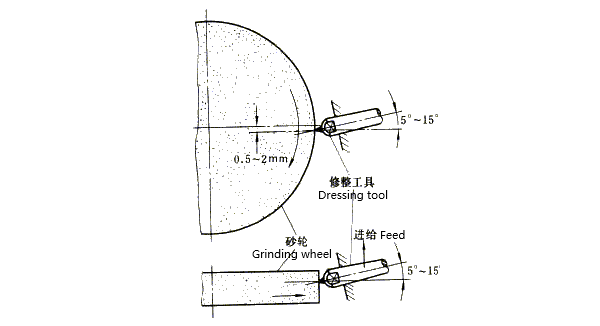

Grinding wheel dressing method

2020-09-23In the grinding process, under the action of friction and extrusion, the edges and corners of the grinding wheel gradually become blunt, or when grinding the ductile material, the grinding chips are easy to embedded in the pores of the grinding wheel surface, causing the surface of the grinding wheel to be blocked, and finally causing the grinding wheel to lose its cutting ability

Learn More

-

Analysis of Causes of Burning Workpieces on High Speed CBN Grinding Wheel

2020-09-22When the high-speed CBN grinding wheel is grinding the workpiece, we often find that there will be burns on the surface of the workpiece, which is related to the high-speed operation of the CBN grinding wheel. The main types of burns on the workpiece are linear or non-continuous linear; the grinding direction of the deformed grinding wheel shows two types of black spot-like burns.

Learn More

-

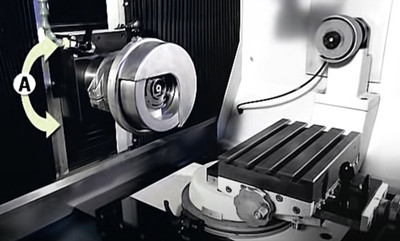

Ewag RS-15 Series Diamond Tool Grinder

2020-09-18The RS series manual universal grinding machine of Ewag have excellent performance in grinding superhard materials such as PCD tool edges for over 30 years. Ewag manual grinding machines are used to grind high-precision micro-tools made of carbide, steel or other materials. In addition, our machines can withstand the rational manufacturing and re-sharpening of polycrystalline diamond and carbide tools.

Learn More

-

Dressing skill of grinding wheel

2020-09-15Sharpening is a process of sharpening the grains of a super hard grinding wheel. In this process, it is necessary to form a sharp cutting edge in addition to the binding agent between the grinding grains and the grinding grain of blunt grinding wheel, so that the grinding grains with strong grinding properties can be highlighted with the binding agent. Trimming must also remove tiny materials from the pores on the surface of the grinding wheel to prevent the increase of grinding force acting on the grinding wheel, which will cause vibration and burn on the surface of the parts.

Learn More