RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

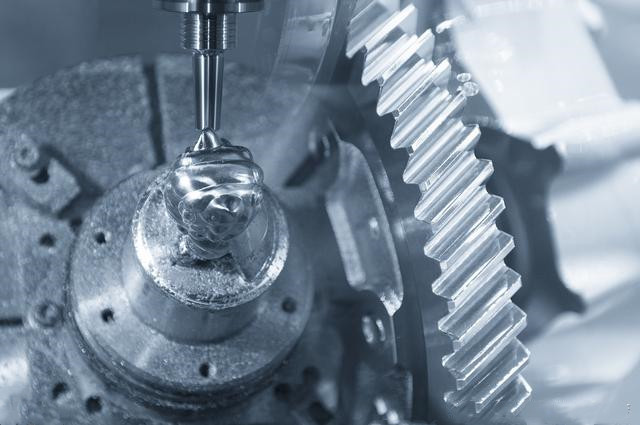

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

THE 15thCHINA INT’L MACHINE TOOL & TOOLS EXHIBITION

2020-09-14The China International Machine Tool & Tools Exhibition(CIMES) will be held at the Beijing International Exhibition Center from September 7 to 11, 2020. CIMES is the largest international machine tool and tools exhibition since EMO in Germany and IMTS in Chicago, USA. It has been held in Beijing biennially since 1992, which has won great favor and support in both domestic and foreign manufacturing industry, equipment users and foreign trade circulation enterprises. After nearly 30 years’ development, CIMES has made huge progress concerning internationalization. Over 1,300 manufacturers from 32 countries and regions take part in every session, with on-site reports from over 200 domestic and overseas media.

Learn More

-

Shaft Grinding Defects and Solutions

2020-09-11Through grinding of centerless grinding machine is a grinding process in which the workpiece is pushed into the grinding zone from the front of the machine tool onto the supporting plate and guide plate, and then through the grinding zone from the back of the machine tool. It is mainly suitable for processing cylindrical and disc-shaped parts, and other parts such as short cones can be processed through special changes. In this processing process, improper selection and adjustment of grinding wheels, guide wheels, pallets, guide plates, feed and lead rollers, and cutting fluid will cause grinding defects, which will affect the processing accuracy.

Learn More

-

Wear Mechanism of Diamond Grinding Wheel in Processing Hard and Brittle Materials

2020-09-10When using diamond tools to process hard and brittle materials, due to the effect of severe friction and high temperature, the tools will inevitably wear away, which is a very complicated process.

Learn More

-

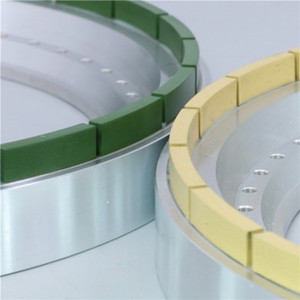

CBN wheel for Cylindrical external grinding

2020-09-09Application : Cylindrical external grinding

Wheel sizes:1A1 Ø500-50T-30U-6X-400J-203,2

Learn More

-

Different from the past grinding -HVOF grinding technology

2020-09-03The HVOF coating materials in aviation parts has had a positive impact on the aerospace industry. HVOF coating materials are not only more environmentally friendly but also more resistant to wear and tear and therefore last longer. During the migration, there is also a shift in the grinding process used to produce the parts. While resin-bonded diamond wheels are an old standard, vitrified bonded diamond wheels are now more popular because resin-bonded diamond wheels cannot be dressed in machines. This poses a challenge to maintaining consistency. By using a vitrified bonded diamond grinding wheel, one can use a rotary dresser and a rotary dressing diamond wheel on the spindle to dress the grinding wheel. This breaks the situation that diamond grains can only be bonded in the grinding wheel, creating a completely new cutting surface on the grinding wheel. Bonding operations can be done online and during the manufacturing process

Learn More

-

Magnesia grinding wheel

2020-09-02Calcined at 800 ~ 850℃, calcined with natural magnesite as raw material, magnesia is a kind of fine powdery gas rigid cementation material. The color is pure white, or gray, or near pale yellow, fresh material has a shimmering glassy sheen. Specific gravity 3.2, bulk density 800 ~ 900 kg/m3, magnesia content not less than 75%, coagulation time: initial coagulation no earlier than 40 minutes, final coagulation no later than 7 hours.

Learn More

-

Grinding process VS Rolling processing

2020-09-01Grinding process and rolling process can improve the dimensional accuracy of parts and reduce the surface roughness.But there are the following differences.

Learn More

-

The History and Types of Gear

2020-08-31A gear is a kind of machine element in which teeth are cut around cylindrical or cone shaped surfaces with equal spacing. It is widely used in mechanical transmission and the whole field of machinery.

Learn More

-

Four methods of grinding wheel dressing

2020-08-28The process of shaping or trimming the blunt surface of the grinding wheel with a dressing tool to restore the grinding performance and correct geometry of the working surface. Timely and correct dressing of grinding wheel is an indispensable link to improve grinding efficiency and ensure grinding quality. Grinding wheel dressing generally includes turning, diamond roller, grinding and rolling, etc.

Learn More

-

Analysis of blockage factors of grinding wheel

2020-08-26The influence of grinding wheel linear velocity is more complex, because of the increase in wheel linear velocity grinding grain of the maximum cutting depth is reduced, chip cross-sectional area is reduced, cutting and grinding heat increases at the same time, the two factors can make jam quantity increases, but when the grinding wheel linear velocity up to a certain extent, such as more than 50 m/s) grinding wheel blocking quantity drops greatly.

Learn More