RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

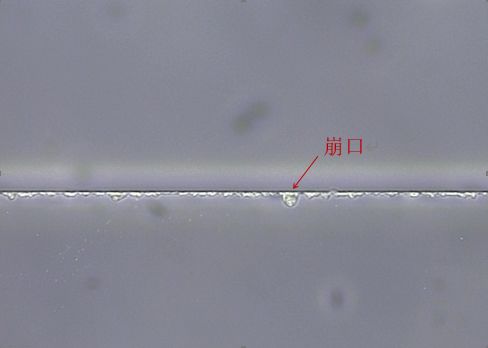

Control method of glass grinding edge chipping

2020-08-25The most common problem encountered when grinding glass is that the amount of edge chipping exceeds the range ,so why does edge chipping occur? The reason is that glass has an amorphous and irregular non-crystalline structure, which means that edge chipping is inevitable and random when grinding glass. The input determines the output effect in the grinding system. The four major input factors are equipment, tools, parameters, and workpieces. The edge chipping is the result of the combined effect of these factors.

Learn More

-

Honing is a three-in-one metalworking process

2020-08-24Honing is the ultra-precise machining process trusted by job shops and high-production manufacturers to create parts that perform at the highest levels of speed and efficiency. No boring or grinding process is capable of delivering such fine levels of roundness, straightness and surface detail. When integrated into your manufacturing process, honing is the difference between a part that works and a part that performs.

Learn More

-

Automobile box processing program-overall PCBN face milling insert and cutter

2020-08-21Learn More

-

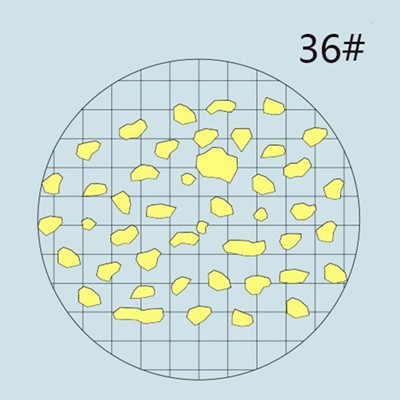

Diamond and CBN Abrasive Grain Size Control

2020-08-19Mesh refers to the number of holes on the screen per square inch, 50 mesh means 50 holes per square inch, 500 mesh is 500, the higher the mesh, the more the holes, and the smaller the abrasive particle size. The finer the granularity. The filter screen divides the abrasive grains into different sizes.

Learn More

-

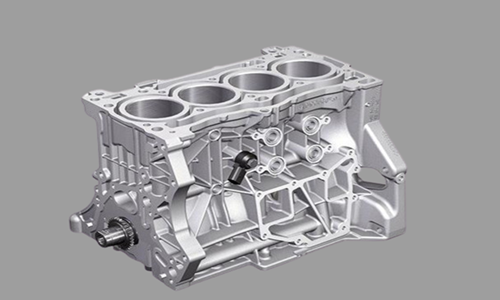

Metal Honing Stones Automotive Engine

2020-08-18Metal honing stones for Cylinder block and Connecting rod

Learn More

-

How to prevent vibration of grinding wheel machine?

2020-08-17The vibration of the grinding machine will directly affect the grinding quality of the workpiece. For example, due to the vibration will cause the workpiece ripple, roughness difference and vibration crack, etc.

Learn More

-

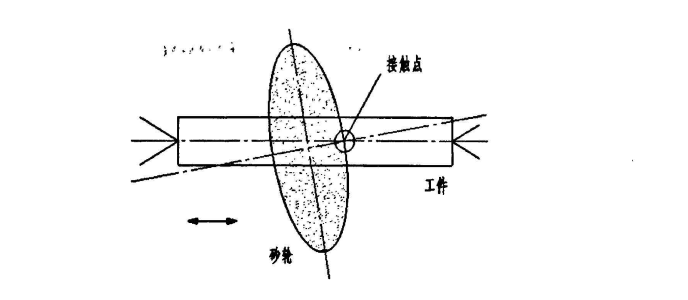

Quick-point Grinding Technique

2020-08-14Working principle of fast point grinding process: when grinding the outer circle of the workpiece, the grinding wheel is in point contact with the workpiece.

The grinding of a grinding wheel on the workpiece is similar to the turning of a tiny knife tip on the workpiece with very little grinding force and heat.

Learn More

-

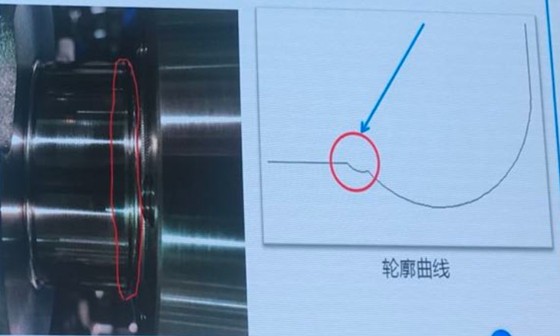

Why is there concavity or protrusion on the surface when grinding crankshafts?

2020-08-13Confirm the position of the grinding wheel and whether the grinding wheel is installed in place After replacing the vitrified CBN grinding wheel.

Learn More

-

Grinding characteristics of electroplated diamond abrasive belt

2020-08-11Diamond solidified grinding wheel is a rigid abrasive. In the process of grinding, there are problems such as poor self-sharpness, easy edge breakage and high product rejection rate. Especially for hard and brittle material workpiece that needs to be processed into curved surface, such as automobile windshield, it is difficult to keep the processed surface in its original shape when grinding with rigid grinding wheel.

Learn More

-

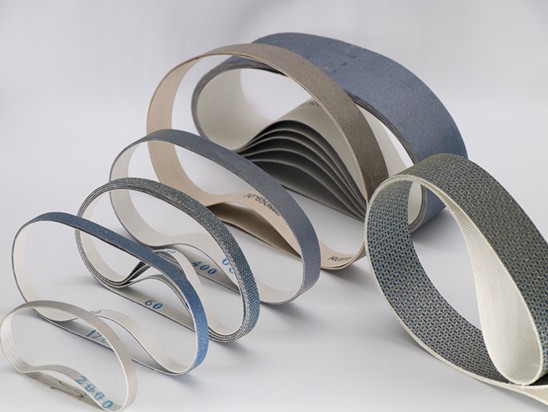

The Grinding Process of Abrasive Belt

2020-08-10Abrasive belt is a kind of belt-shaped tool that can be ground and polished, which is made by bonding abrasives to flexible materials such as paper and cloth using adhesives. Its basic composition is : base material, abrasive and binder, collectively called the three elements of abrasive belt. Abrasives are mainly used for grinding and constitute the main body of abrasive tools. Diamond is selected as abrasive for diamond abrasive belt.

Learn More