RELATED BLOG

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05

-

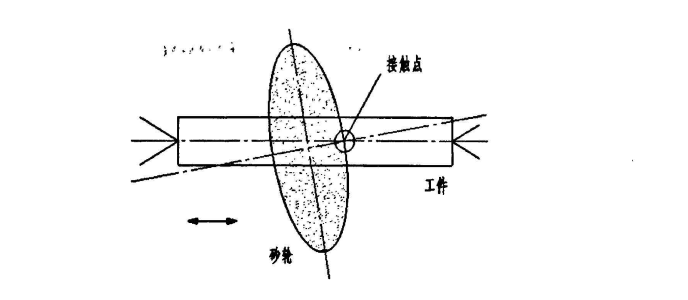

Quick-point Grinding Technique

2020-08-14Working principle of fast point grinding process: when grinding the outer circle of the workpiece, the grinding wheel is in point contact with the workpiece.

The grinding of a grinding wheel on the workpiece is similar to the turning of a tiny knife tip on the workpiece with very little grinding force and heat.

Learn More

-

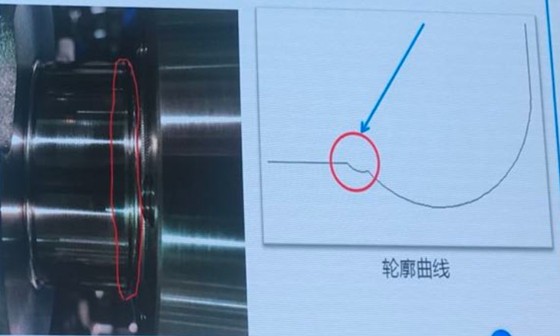

Why is there concavity or protrusion on the surface when grinding crankshafts?

2020-08-13Confirm the position of the grinding wheel and whether the grinding wheel is installed in place After replacing the vitrified CBN grinding wheel.

Learn More

-

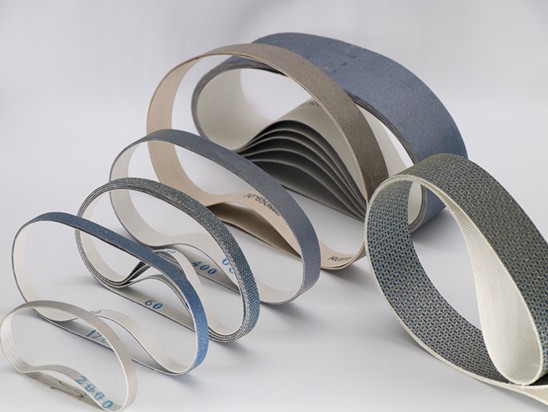

Grinding characteristics of electroplated diamond abrasive belt

2020-08-11Diamond solidified grinding wheel is a rigid abrasive. In the process of grinding, there are problems such as poor self-sharpness, easy edge breakage and high product rejection rate. Especially for hard and brittle material workpiece that needs to be processed into curved surface, such as automobile windshield, it is difficult to keep the processed surface in its original shape when grinding with rigid grinding wheel.

Learn More

-

The Grinding Process of Abrasive Belt

2020-08-10Abrasive belt is a kind of belt-shaped tool that can be ground and polished, which is made by bonding abrasives to flexible materials such as paper and cloth using adhesives. Its basic composition is : base material, abrasive and binder, collectively called the three elements of abrasive belt. Abrasives are mainly used for grinding and constitute the main body of abrasive tools. Diamond is selected as abrasive for diamond abrasive belt.

Learn More

-

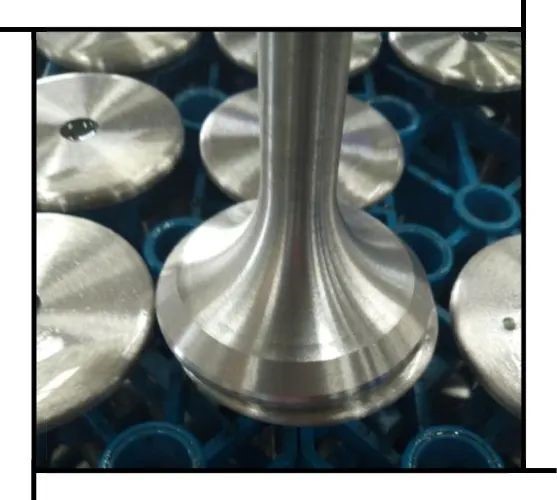

Example of New-type Six Valve Grinding

2020-08-07The grinding characteristics of valve material in grinding. The abrasive debris is easy to adhere to the surface of the grinding wheel, filling the pores between the abrasive grains, and the grinding wheel loses its grinding ability. This phenomenon is most obvious in high nickel materials, followed by austenitic stainless steel, and martensitic stainless steel is lighter.

Learn More

-

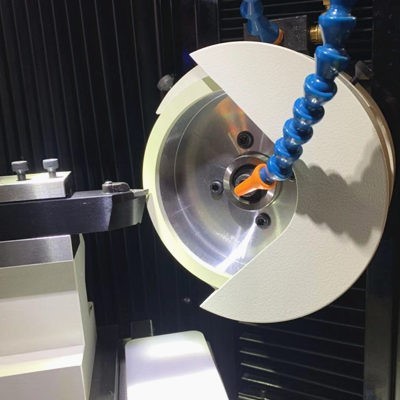

Tips for Agathon Grinding Machine

2020-08-06As is known to all, cermet inserts are widely used in the field of finish milling and turning with excellent performance. When use the Agathon machine to grind the small radius of cermet inserts, its precision, smoothness and the perfect degree of arc tangency still superior to others up to now.

Learn More

-

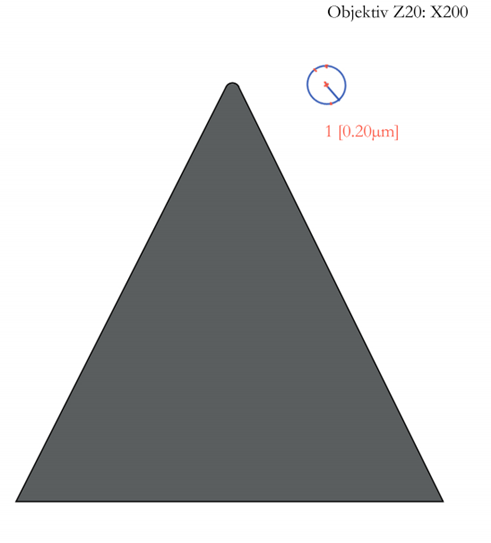

Selection and Characteristics of PCD and PCBN Cutting Tools

2020-08-05Fine-grained grinding wheel is used for fine processing, the contact area is small, the grinding force is low (100-200N), and the grinding heat is low, but the material removal rate is low. This stage is mainly through grinding and polishing to further improve the quality of the cutting edge. Finishing is among the two.

Learn More

-

Chongqing Extreme Grinding Processing Technology Seminar

2020-08-05On July 30th, the highly anticipated “2020 Extreme Grinding Processing Technology Seminar” ushered in the registration day. This meeting is the first large-scale event held in my country’s superhard materials industry since the epidemic. In response to the current domestic and international epidemic situation and Chongqing’s local prevention and control requirements, the organizers of the conference will ensure the health of the delegates during the conference in accordance with the basic principle of “internal control and external prevention”.

Learn More

-

Case of Diamond Belt for thermal spraying industry

2020-08-04Parameter

–MORE R&d and Testing Center

–Resin Bond Flexible diamond belt polishing of tungsten carbide thermal spraying coatings

-‐LEHIII/F: Variable speed cutter grinder

Learn More

-

Worm and gear grinding wheel

2020-07-31Worm grinding wheel is mainly used for high precision grinding of spur gear, helical gear, bevel gear, crankshaft, worm wheel and worm, etc. It has the characteristics of good shape retention, high gear grinding accuracy and high productivity. Worm grinding wheel is mainly used for high precision grinding of spur gear, helical gear, bevel gear, crankshaft, worm wheel and worm, etc. It has the characteristics of good shape retention, high gear grinding accuracy and high productivity.

Learn More