RELATED BLOG

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05

-

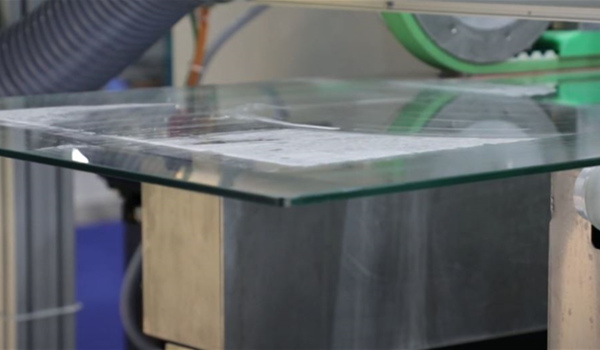

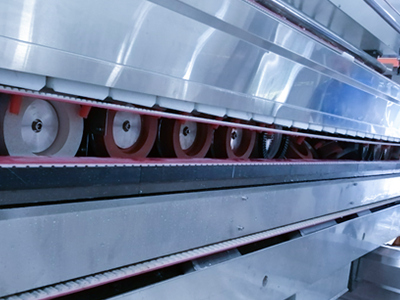

Solutions for glass edges grinding

2024-07-03More SuperHard has been in glass field for more than 10 years and supplies complete processing solutions for furniture and architecture glass.

We manufacture Glass Grinding and Polishing Wheels available for use on double straight-line edging machines, bevelling machines, high-speed seaming machines, Profiling machines etc.

After the original glass is produced, the edge of the glass is very sharp and generally needs to be edged. After edge grinding, the glass can play the following roles:

1. Grind off the sharp edges caused by cutting to prevent scratches during use.Learn More

-

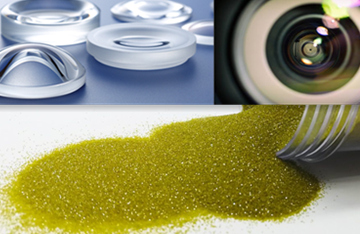

Problems and solution of diamond tools in optical glass processing

2024-05-20Optical glass substrates are usually processed by cutting, rolling, rough grinding, fine grinding, polishing, edge grinding, coating, gluing, and ink coating. After the optical lens is finely ground with abrasive fluid, there is still a thick crack layer on the surface. The method to eliminate this crack layer is polishing. In the edge grinding/grinding/polishing process, abrasive fluid and polishing powder are needed to assist the operation.

Learn More

-

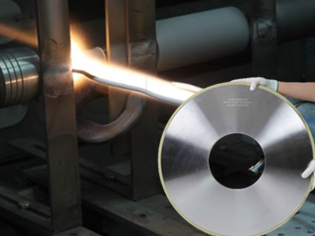

How are vacuum brazed diamond tools made?

2024-04-18Moresuperhard vacuum brazed diamond tools for cutting, grinding, drilling foundry, metal working, composites, automotive sector,cast iron, angle iron, ductile iron, carbon steel,etc.

Learn More

-

Moresuperhard at Grinding Hub 2024

2024-04-16Moresuperhard will take part Grinding Hub2024 with more products to show, Moresuperhard Booth is H10 B85. Know more details please follow us to know more wonderful knowledge.

Learn More

-

Diamond polishing powder for optical lenses polishing

2024-04-15There are three mainstream polishing methods for optical lenses: mechanical polishing, chemical polishing and chemical mechanical polishing. All three require grinding polishing fluid (powder), which can be divided into diamond polishing powder and diamond compound (the industry also calls polishing fluid abrasive fluid or grinding fluid abrasive fluid). Generally, diamond compound is used for rough grinding, and diamond polishing powder is used for precision grinding. diamond Polishing powder is usually used in the next step of the grinding fluid.

Learn More

-

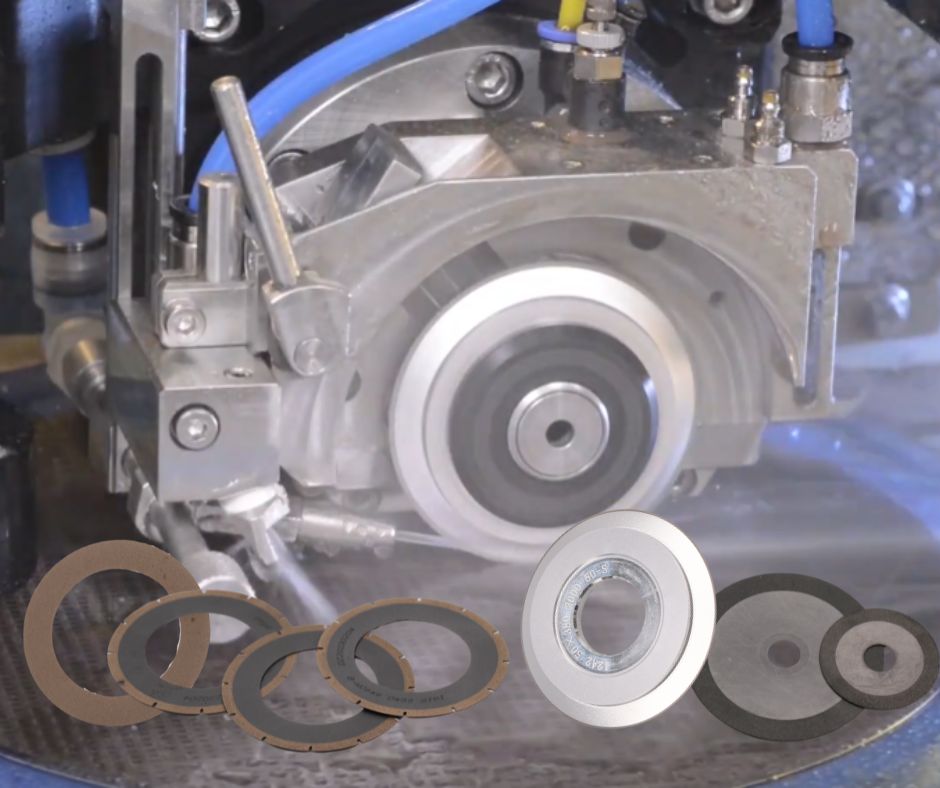

How to select diamond dicing blade for precision dicing ?

2024-04-09Resin bonded diamond dicing blades can be used to cut quartz, glass, lithium niobate, crystals and other brittle and hard materials, IC packages (QFN, DFN), etc.

Metal bond diamond dicing blades can be used to process optical devices, ceramics, ferrite, quartz, IC packaging (BGA), optical communications (Faraday), etc.

Learn More

-

What diamond tools are used to process glass lense?

2024-04-06Moresuperhard can provide grinding wheels(milling grinding wheel and centering wheel) and polishing tools(diamond pellets and polishing pad) for lense processing.

Learn More

-

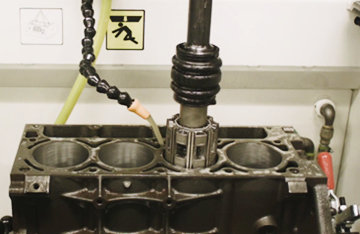

Honing process and its application in automobile parts manufacturing

2024-03-07Honing Process is a special form of grinding and an efficient processing method in finishing. This process can not only remove large machining allowances, but is also an effective processing method to improve the dimensional accuracy, geometric shape accuracy and surface roughness of parts. It is widely used in the manufacturing of automotive parts.

Learn More

-

How to grind plasma spray coating?

2024-01-09Grinding of the outer circle and inner hole: The circumferential surface of the grinding wheel is mainly used as the grinding working surface, which is tangent to the machined surface of the part, and the sprayed surface of the outer circle and inner hole is ground.

When the hardness of plasma spraying is relatively high and the processing volume is relatively small, the coating treatment is more suitable for grinding. Because plasma spraying has a special structure, it makes the coating material more difficult to grind. The selection of coating grinding methods and process specifications mainly depends on the structure and hardness of the coating. Reasonable selection of grinding methods and process specifications can not only improve the surface finish and grinding efficiency of the coating, but also reduce the stress at the interface between the coating and the substrate. According to the form of the grinding wheel working surface, there are basically two methods for plasma spraying.

Learn More

-

Grinding problems for the glass industry

2023-12-01The edge grinding process can effectively improve the brittleness of the glass, making the glass more beautiful and safer. Generally speaking, it is enough to use a coarse grinding wheel to grind off the corners of the glass. However, the requirements for craft decorations are higher and require rough grinding and fine grinding to make the original glass of different shapes and sizes gradually close to the workpiece required by the customer. size and surface roughness.

Learn More