RELATED BLOG

-

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05 -

Application of CBN Superfinishing Oilstones in Bearing Raceways

2025-10-16

-

What factors affect the blockage of grinding wheel?

2020-07-28Here let’s talk about some important factors which affect the blockage of grinding wheel. Generally we consider the following aspects:the Influence of Grinding Wheel Itself, the Influence of Machining Parameters, Grinding Fluid and Grinding Way.

Learn More

-

Diamond rotary dresser for crankshaft grinding wheel

2020-07-28Dressing with rotating diamond tools has been found to be a reliable technique in series and performance grinding processes, especially those applications using vitrified bonded grinding wheels.

The automotive and -supply industry for grinding crankshafts.

Learn More

-

Common Safety Knowledge of Grinding Wheel

2020-07-21Before starting the machine, check the protective device of the machine and the reset switch of various movements, to see whether it is adjusted in place firmly.

Learn More

-

Deformation control test of integral blade disc CNC abrasive belt grinding

2020-07-17The test uses a certain type of aero engine titanium alloy integral disc, as shown in Figure 14. The precision milling process has been completed before the abrasive belt grinding.

Learn More

-

Research on the deformation behavior of CNC abrasive belt grinding of integral blade disc

2020-07-17In the grinding of the blade surface of the whole blade disc, the thickness of the thinnest part of the blade is less than 1 mm, which is a typical thin-walled weak rigid part. At the same time, due to the narrow channel between the blades of the whole blade disc, it is difficult to design a tooling fixture that balances the grinding positive pressure for the grinding object, so that the workpiece undergoes weak rigid bending deformation of the ground part under the action of the grinding positive pressure.

Learn More

-

Grinding process analysis of integral blade disc CNC abrasive belt

2020-07-15The grinding process of the abrasive belt on the blade surface of the integral blade disk is shown in Figure 2: The contact rod of the grinding head forms a constant angle φ with the surface of the workpiece, and the contact wheel supports the abrasive belt and clings to the integral blade under the action of the grinding contact pressure Fa The disc blade profile; the belt drive roller drives the belt at a constant linear speed vs. at the same time, the grinding head performs a feed motion at a speed vf to realize the grinding of the belt on the blade surface.

Learn More

-

Diamond dicing blade cutting PCB

2020-07-10PCB is printed circuit board, short for printed board, is one of the basic components of the electronic industry. PCB is used in almost all electronic devices, from electronic watches and calculators to computers, communication electronic devices and military weapon systems. As long as there are integrated circuits and other electronic components, PCB should be used in order to make the electrical interconnection between each component.

Learn More

-

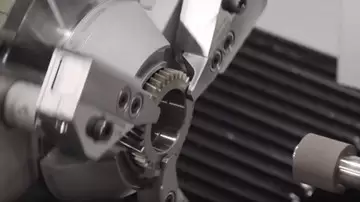

Gear Processing

2020-05-27The use of a disc-shaped modular milling cutter or a finger milling cutter to mill teeth belongs to the forming method. The cross-sectional shape of the milling cutter teeth corresponds to the shape of the gear teeth. This method has low processing efficiency and processing accuracy, and is only suitable for single-piece small batch production.

Learn More

-

Segmented edge and continuous edge diamond coated band saw blades

2020-05-27Diamond Band Saw Blades have proven the be an effective diamond machining tools on a large variety of materials and applications. With diamonds firmly attached to ultra-thin metal body, Diamond Band Saw Blades remain the tool of choice for many diamond cutting and machining jobs. Only the highest quality raw materials are used in the manufacturing process. Manufacturing process is carefully controlled, matching your application with the right bond type, grit size, bond hardness and composition.Learn More

-

Bearing grinding knowledge: the secret of successful grinding wheel dressing

2020-05-27The key factors that can maximize the grinding performance of grinding wheels are good shaping and sharpening tools (commonly known as dressing) and skilled dressing skills. In fact, an operator with a high quality dressing tool and a good knowledge of dressing the grinding wheel can always maintain a high grinding performance of the wheel. Instead of just buying the so-called good grinding wheel. This is very important because the workshop cannot be equipped with special grinding wheels for everyone.

Learn More