RELATED BLOG

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05

-

Bearing grinding knowledge: the secret of successful grinding wheel dressing

2020-05-27The key factors that can maximize the grinding performance of grinding wheels are good shaping and sharpening tools (commonly known as dressing) and skilled dressing skills. In fact, an operator with a high quality dressing tool and a good knowledge of dressing the grinding wheel can always maintain a high grinding performance of the wheel. Instead of just buying the so-called good grinding wheel. This is very important because the workshop cannot be equipped with special grinding wheels for everyone.

Learn More

-

Common grinding wheel dresser

2020-05-27A single point dresser is formed by placing a diamond rough or shaped diamond on the tip of a metal handle.

Learn More

-

What is grinding?

2020-05-08Grinding processing is a processing method that removes excess layers on the surface of the workpiece by means of the cutting effect of the abrasive tool, so that the surface quality of the workpiece reaches predetermined requirements.

Learn More

-

Abrasive belt grinding

2020-05-08Abrasive belt grinding is a process method in which the moving abrasive belt is brought into contact with the workpiece in a corresponding contact mode according to the shape of the workpiece.

Learn More

-

How to choose the appropriate grinding amount of grinding wheel?

2020-04-27The grinding speed of superhard abrasive wheel should be according to the grinding wheel type, grinding mode and cooling. The grinding efficiency and grinding ratio can be significantly improved by increasing the grinding speed of the grinding wheel (for example, the grinding speed of the grinding wheel can be increased by 40%, and the grinding ratio can be doubled) and the grinding cost can be reduced.Learn More

-

The production of synthetic diamond powders

2020-04-14That is the equipment offering pressure and temperature needed for synthesis of superhard material, which produce ultra-high pressure through hydraukic system and high temperature through high-power current. it is also the equipment widely used in national superhard material industry. The Super-hard material cubic hydraulic press can form 4-6Gpa,up to 2000ºC ultra high pressure, high temperature environment within 100cm³ area of the cell. it is the equipment which is widely usedin producing super-hard material, researching high pressure physics, limiting material and geophysics.

Learn More

-

Problems to be noticed in cylinder hole honing

2020-04-08The honing allowance should be suitable. Small allowance, can not fully eliminate the inherent error of cylinder bore, re-establish precision. Large allowance, long time of honing, low processing efficiency, fast wear of honing stone, high processing cost and poor processing accuracy, unstable quality.Learn More

-

Automotive engine casting aluminum alloy cylinder block processing

2020-04-08Cylinder block is the basic part of the engine, but also the key part. The upper surface is the mounting surface of the cylinder head, the lower surface is matched with the oil pan, the front cover is the front cover, the rear is the transmission, the left and right sides are respectively the intake and exhaust surface. Cylinder block reciprocating movement of piston cylinder hole and installation of crankshaft main bearing hole, more densely covered with oil channel, channel, large and small positioning holes and threaded holes.

Learn More

-

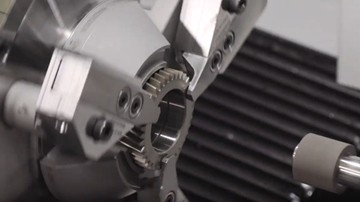

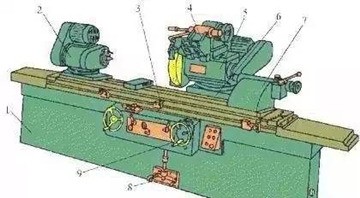

Cylindrical Grinder Structure

2020-04-08The following figure is the outline drawing of M1432A universal cylindrical grinder. The meaning of the M1432A number is: M—grinding machine class; 1—external cylindrical grinding machine group; 4—general code of universal cylindrical grinding machine; 32—1 / 10 of the maximum grinding diameter, the maximum grinding diameter of the machine is 320mm; A major improvement in performance and structure.

Learn More

-

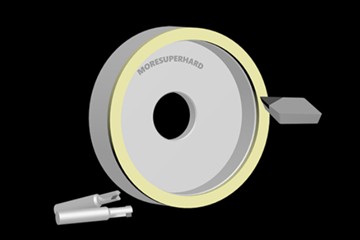

Vitrified CBN internal wheel for bearing bore

2020-03-30Vitrified CBN internal wheel for bearing bore

Learn More