RELATED BLOG

-

How to Choose the Right Vacuum Brazed Diamond Tool

2025-12-17 -

How to Select the Right Polishing Pad Material for Different Sapphire CMP Stages

2025-12-07 -

Which Grit Wheel Should You Choose for Wood Turning Tools?

2025-12-04 -

Difference Between CVD Diamond Roller Dresser and Electroplated Diamond Roller Dresser

2025-11-18 -

How to grind suspension springs?

2025-11-11 -

How to machining carbon-ceramic brake disc?

2025-11-05

-

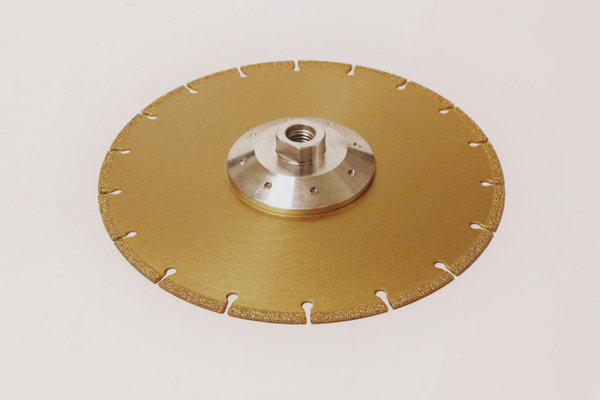

Vacuum blazed diamond grinding wheel

2019-12-05Advantages of brazing process: Ni-Cr alloy itself has high strength, and higher bonding strength can be obtained after brazing than silver base alloy, Ni-cr alloy has high melting point and good grinding resistance. However, it still has certain limitations. Due to the high brazing temperature (1080℃), it is easy to cause thermal damage to the diamond and reduce the strength of the diamond. Brazing under vacuum or argon protection ensures that the bonding strength between the alloy layer and the diamond and the steel matrix can be higher and the thermal damage oxidation of diamond can be minimized.

Learn More

-

What Other Properties of CBN Make it Superior for Sharpening Woodturning Tools

2019-12-05One of the objectives of metallurgists as they are developing better HSS (high-speed steels) is to get a more uniform distribution of fine microcrystalline carbides throughout the HSS. This makes the steel far more wear resistant, so the time between tool sharpening is greatly extended. But it is not without its attendant difficulties, namely the sharpening of the carbide grains distributed throughout the HSS

Learn More

-

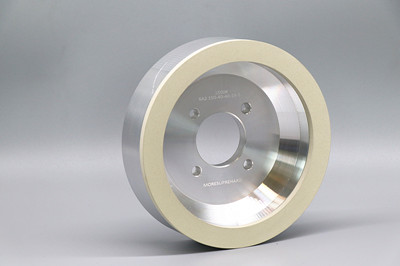

Carbide HVOF coated cylindrical external grinding

2019-12-05Application : HVOF coated cylindrical external grindingWheel sizes: 3A1 Ø500-30T-20U-6X-400J-203 H7Learn More

-

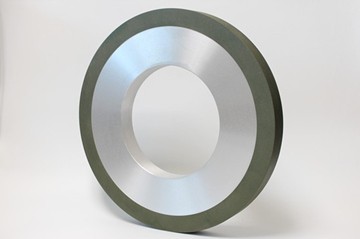

Vitrified bond diamond grinding wheel for PCD saw blade grinding

2019-11-29Vitrified bond diamond grinding wheel for PCD saw blade grinding

Learn More

-

Grinding crack generation and solution

2019-11-29The causes of grinding cracks may be as follows: the surface stress of the workpiece exceeds the fracture limit, that is, the workpiece has residual mechanical stress and thermal stress in the surface part due to previous grinding or heat treatment. Because this part of the grinding just to maintain the balance of the stress, resulting in its residual stress over the strength of the workpiece, from some will produce a grinding crack.

Learn More

-

Natural/single crystal diamond tools

2019-11-28Sing crystal diamond tools Suitable for finish machining copper, aluminum and its alloy materials, made in, jewelry, clocks, instruments and meters, LED products, acrylic products, aluminum products, aerospace, automotive and other fields are widely used, such as: motorcycle wheel, turning the camera, cell phone components highlight parts, precious metals, all kinds of hardware highlights shell, table hub, surface calendar window, pen, fishing gear, contact lenses, etc.It has the features of low loss, long life and easy to use and can guarantee high machining precision and mirror finish.Learn More

-

What are the characteristics of glass grinding

2019-11-28The glass is wind-proof, light-permeable, stable in performance, various types have different characteristics due to the use of different occasions, the scope of application is very wide. When we are choosing glass, besides paying attention to price, still answer its kind and performance to have certain understanding, make full use of strong points to avoid weak points, just can find the material that suits to use m

Learn More

-

End face CBN Grinding Wheel For Powder Metallurgy

2019-11-27Powder metallurgy is widely used in automobile, motorcycle and other parts. the work piece precision can reach Ra 0.003mm, the dressing cycle can reach More than 10,000 pieces by using More super hard company’s end face CBN grinding wheel.

Learn More

-

Choose the right dresser for your tools

2019-11-23Dressing stones for grinding wheels are available in many different shapes. Choose from a single point diamond dresser with layered clusters, blade-type dressers with hand set diamonds, and grit dressers with uniform distribution of diamonds. Each dresser will give you a distinct finish. As you apply the grinding wheel dressing stick to the surface of your wheel, you’ll remove the top layer of the wheel and reveal a clean, sharp surface for future projects.

Learn More

-

Which Blade Is Right For You?

2019-11-23Diamond blade saws are more than capable of cutting a variety of materials, so begin by thinking about your needs. For instance, do you want a saw that will work with different things or one that works best with something specific, such as stone or granite.

Learn More