RELATED BLOG

-

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

Maintenance And Use Requirements Of Diamond Saw Blade

2019-11-08Learn More

-

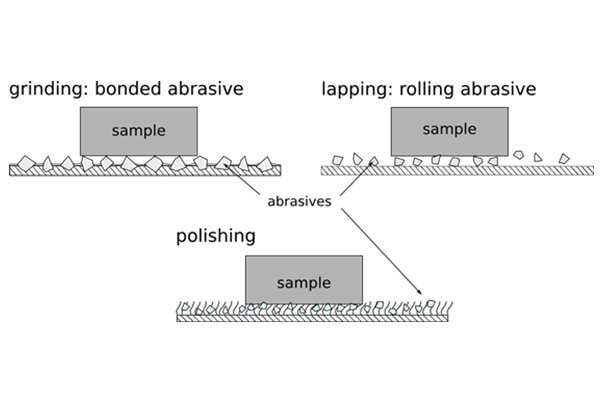

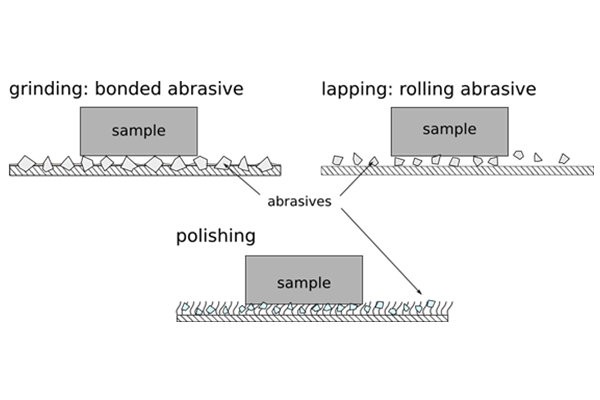

High Precision Ceramic Grinding Lapping

2019-09-27The general purpose of Lapping is to arrange parallelism and flatness and to get accurate alignment of parts. This is grinding method to get flat finished surface with accurate size by cutting the extremely small amount from the surface of workpiece with abrasive’s working after adding abrasive and lapping fluid between the surface of workpiece and surface plate for lapping and moving them relatively to workpiece and lap. However, the existing lapping method is not eco-friendly, difficult to be cleaned and has long working time because it needs lots of abrasive and polishing fluid. More SuperHard makes abrasive of the wheel fixed grain and attaches it to the base for lapping workpiece with wet corrosion to improve the existing lapping method. Abrasive and lapping fluid to be used are reduced with fixed abrasive grain, and eco-friendly, and easily cleaned fresh working environment is available decreasing working time and maintenance cost.Learn More

-

Difference between Lapping and Polishing

2019-09-27Learn More

-

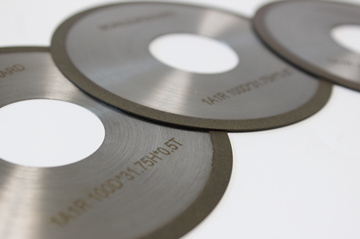

Quality Control For Resin Diamond Wheel for Cylindrical Grinding

2019-09-27Resin Diamond Wheel for Cylindrical Grinding of Thermal Spraying Coatings (915D*50.8T*304.8H*10U ,915D*40T*304.8H*10U )were sent to the UK and dubai. The quality inspection team is testing the size and weight of the grinding wheel.

Learn More

-

EMO Hannover -The world of metalworking

2019-09-24With a share of foreign exhibitors running at approximately 60%, EMO Hannover is the world’s most international metalworking trade fair. As the leading fair of its kind, it serves as a networking hub epitomizing the highest level of expertise among providers and users. EMO Hannover is the only trade fair to tap into the world’s globalized markets – at the heart of Germany, one of the world’s leading machine tool sales markets.

Learn More

-

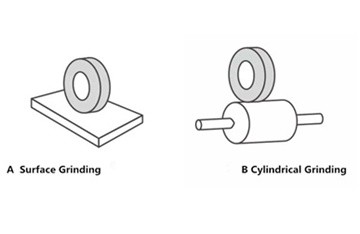

Relationship between grinding resistance and contact area

2019-09-22Therefore, differences in grinding conditions can affect the choice of grinding wheel.

Therefore, the contact area of the face grinding is larger, and the grinding resistance is also larger than that of the cylindrical grinding. (Only see the contact area, all other conditions are the same).

Learn More

-

China International Industry Fair

2019-09-21The China international industry expo (ciie) is the largest exhibition in China’s manufacturing industry.

Learn More

-

Grinding Wheels In The Medical Industry

2019-09-12Diamond plated wheels are used extensively in the creation of dental burs and other tools. Only with the best wheels can you get the best possible dental equipment. Additionally, diamond wheels are used for bone sawing in the mouth too as a way of reaching areas that require serious oral surgery.

Learn More

-

More SuperHard Meet You In CIOE 2019

2019-09-07China International Optoelectronic Exposition (CIOE) was held in shenzheng international convention and exhibition center from September 4 to 7, 2019.More super Hard were invited to attend the exhibition.

Learn More

-

Tips For Selecting The Right Diamond Grinding Cup Wheel

2019-08-25Diamond grinding cup wheels come with a variety of specifications, each meant for different use types. It is thus important to at first identify the nature of the job and then selecting the diamond cup wheel accordingly. For example, in case the workload is going to be pretty heavy (such as grinding of stones and concrete) you will have to get the diamond grinding cups with large diamond segments. The smaller diamond segments are perfect for lighter works, such as epoxy coatings, glues, paints, and other such surface coatings.

Learn More