RELATED BLOG

-

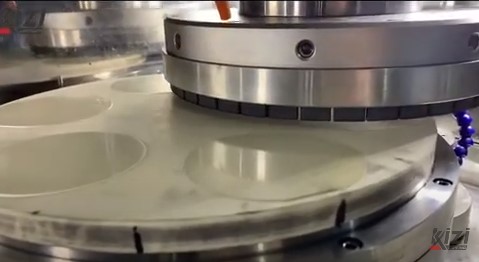

Good feedback of resin CBN grinding wheel for brake disc grinding

2025-02-18 -

What are the advantages of SG abrasives compared with ordinary corundum abrasives?

2025-01-09 -

How to choose polishing film for polishing different material ?

2024-12-26 -

Advantages of power honing for gear processing

2024-12-24 -

How to choose grinding wheel for grinding CNC cutting tools?

2024-12-07 -

How to choose diamond rotary dresser for dressing gear grinding wheel?

2024-09-25

-

CIMT 2023 Share

2023-04-20On April 10-15, 2023, the 18th China International Machine Tool Exhibition (CIMT 2023), sponsored by China Machine Tool Industry Association and co-organized with China International Exhibition Center Group Corporation, will be held in Beijing China International Exhibition Center ( Shunyi Pavilion) was held grandly.

Learn More

-

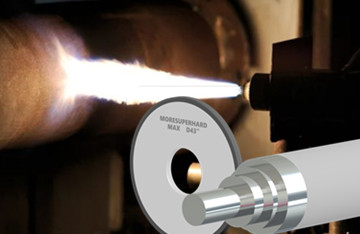

How to process thermal spray coating?

2023-03-30Choose the most suitable grinding wheel bonding type. There are two commonly used grinding wheel binders, vitrified bond diamond grinding wheel and resin bond diamond grinding wheel. The grinding wheel with vitrified bond can withstand high grinding speed and precise fit tolerance, and is not affected by water, acid, oil and temperature changes, but the grinding machine speed is required to be lower than the safe operating speed of the grinding wheel, generally less than 33 m/s. Grinding wheels with resin bonds, on the other hand, can be used for higher grinding speeds and produce higher finishes.

Learn More

-

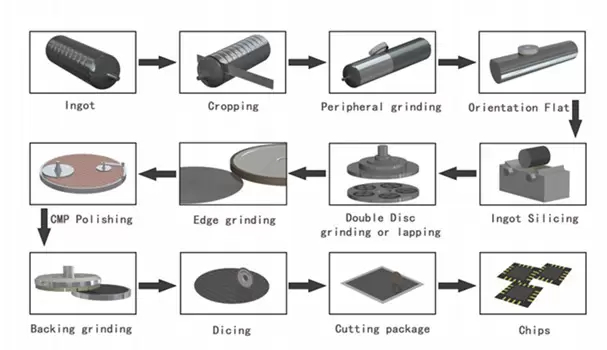

Processing technology of monocrystalline silicon wafer

2023-03-28The processing technology of monocrystalline silicon wafer is mainly as follows:

* Cutting

* Cylindrical grinding ingot

* Slicing

* Chamfering

* Grinding/lapping

* Corrosion, cleaning

Learn More

-

How to choose dressing speed?

2023-03-16During the grinding process, the state of the grinding wheel will directly affect the grinding result. The state of the grinding wheel includes changes in the cutting force and shape of the grinding wheel. These changes will affect the yield and reproducibility of the ground product.

Learn More

-

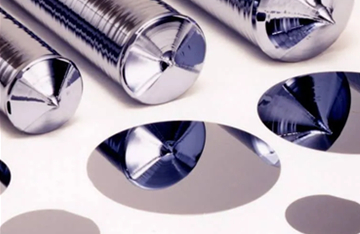

How are semiconductor wafer manufactured?

2023-03-13A wafer is a thin silicon wafer with a thickness of about 1 mm. Due to the very high requirements of the manufacturing process, the surface of the wafer has a very high flatness. The specific application of the wafer determines which crystal growth method needs to be adopted. Taking the Czochralski method as an example, after the polysilicon is melted, a pencil-sized seed crystal is immersed in the molten silicon, and then the seed crystal is slowly rotated and slowly pulled upward. So a very heavy monocrystalline silicon ingot was pulled out. In addition, targeted electrical properties of the wafer can be achieved by adding trace amounts of high-purity dopants to the molten silicon. Ingots are doped according to customer specifications, then sliced and polished. After several steps, customers receive wafers specially packaged to their specific specifications.

Learn More

-

What is the difference between electroplated diamond sanding belt and resin diamond sanding belt?

2023-03-10In terms of binder, the resin diamond abrasive belt mainly uses phenolic resin plus a small amount of metal powder as the binder, while the electroplated diamond abrasive belt is a kind of sand that deposits nickel-drill alloy on the surface of the metal substrate and fixes the diamond abrasive by electrodeposition. With production process.

In terms of processing efficiency, since the electroplated diamond abrasive belt uses higher-grade abrasives and has only one layer of abrasive, it has its own advantages in heat dissipation and other aspects, so the electroplated diamond abrasive belt has higher processing efficiency.

Learn More

-

How to choose the hardness of diamond grinding wheel?

2023-03-01When the hardness of the grinding wheel is selected properly, the diamond or CBN electroplated grinding wheel will automatically remove the blunt abrasive grains during the grinding process, exposing new sharp abrasive grains to continue grinding. If the selected grinding wheel is too soft, the abrasive grains will fall off prematurely before passivation, which will not only increase the consumption of the grinding wheel, but also cause the grinding wheel to lose its correct shape and affect the machining accuracy; if the selected grinding wheel is too hard, the abrasive grains will not fall off in time after passivation, which will cause The gap between the abrasives on the surface of the grinding wheel is blocked by grinding debris, resulting in increased grinding force, increased grinding heat, and increased grinding temperature, resulting in deformation or even burns of the workpiece, and increased surface roughness and reduced productivity.

Learn More

-

Application hybrid CBN grinding wheel for medical stainless cutting tools

2023-02-08Difficult-to-machine materials, complex workpiece shapes and frequent small-batch production place high demands on the tools used to process medical materials. The precision tools produced by Walter enjoy a high reputation in this field.

Medical materials, such as implant products and prosthetics, play an important role in successful surgical procedures, helping surgeons achieve optimal medical outcomes. Cutting tools for processing medical materials determine the quality of medical materials to a large extent. The use of cutting tools in the manufacture of medical materials is diverse and extensive. It can process relatively simple workpieces such as large-scale equipment (such as computerized tomography cameras), while the production of implanted products or workpieces used to repair the skull or treat fractures. more challenging.Learn More

-

What is the sapphire window and what is it used for?

2022-11-21Sapphire has high hardness and is a hard and brittle material at room temperature, which is difficult to process and has a low yield. Especially in the process of precision and ultra-precision processing, sapphire sheets often have cracks, scratches, edge breakage and other defects.

Learn More

-

Cylindrical grinding method and the choice of grinding allowance

2022-11-16Many shapes, sizes and types of bearings exist including: ball bearings, roller bearings, needle bearings, and tapered roller bearings.

Learn More